LUBRICATION

A

WARNING: NEVER attempt to lubricate the

NOTE: Replace the Hydrostatic/Hydraulic Oil

•

Skid Steer Loader with the engine running. and Filter after the first 10 hours of operation

Remove the Ignition Key to prevent

unauthorized or unexpected starting.

NOTE: Log the date of Lubrication in the Main-

•

tenance Schedule.

GENERAL INFORMATION

NOTE: Properly lubricate the entire Loader

•

and replace engine

011

after the first 25 hours of

operation. Repeat lubrication and

011

replacement at

regular 50 hour intervals thereafter. Under more

strenuous operation and/or

in

extremely cold

weather conditions or dusty conditions, change oil

and lubricate the Loader more often

as

necessary.

It

is

well

to

remember that a sufficient amount

of

oil and

grease will prevent excessive component wear and early

failure.

ENGINE OIL

Refer to Engine Manual provided for engine oil

requirements and type recommendations.

On

a daily

basi

s,

check the Oil Dipstick for level indication and

replenish

as

necessary.

HYDRAULIC & HYDROSTATIC OIL

The Hydraulic and Hydrostatic systems share the same

fluid and Reservoir. Reservoir capacity

is

5

V.S.

gallons

(19 liters). Maintain the oil level

at

approximately 2"

from the top

of

the Reservoir; do

NOT

overfill

as

this will

force oil out the Vent Cap.

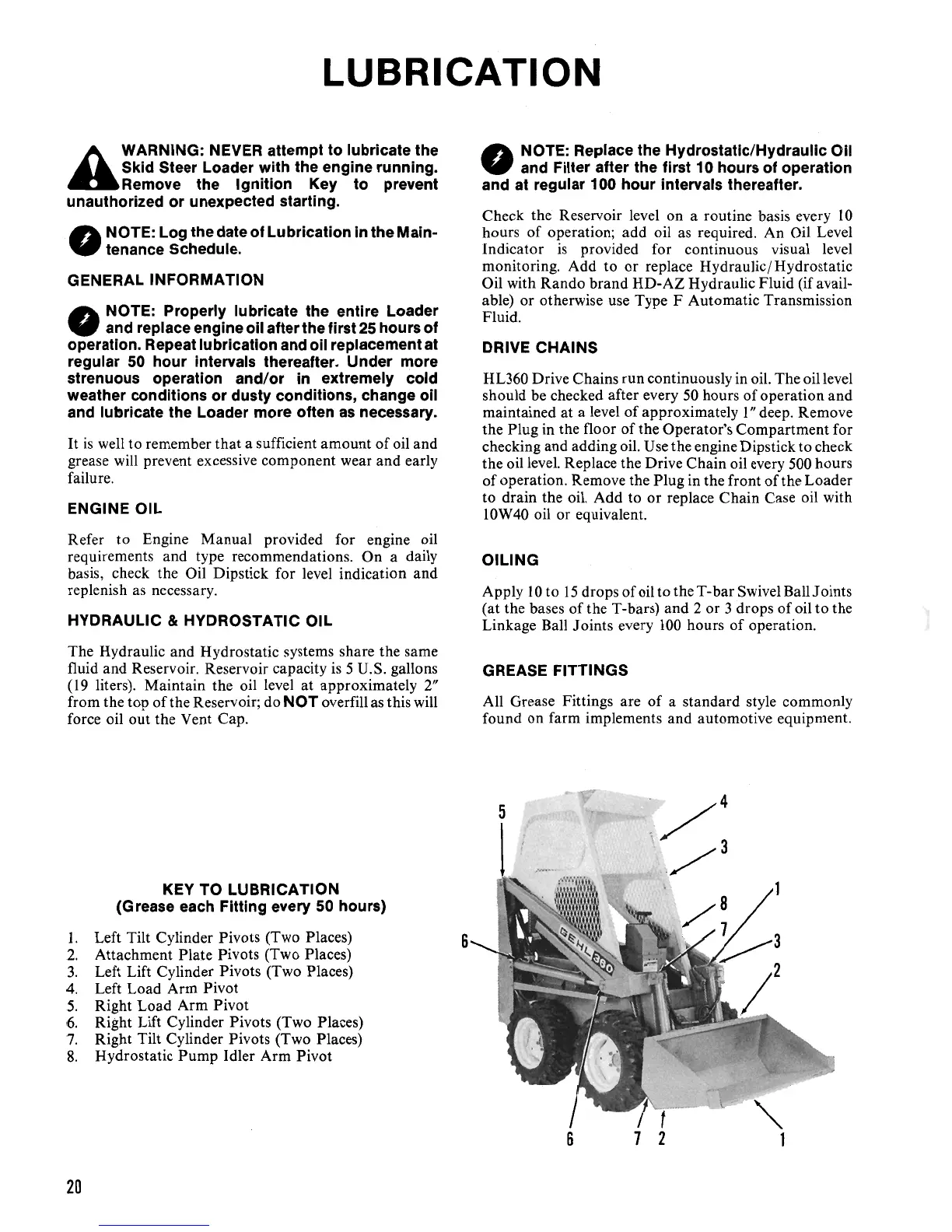

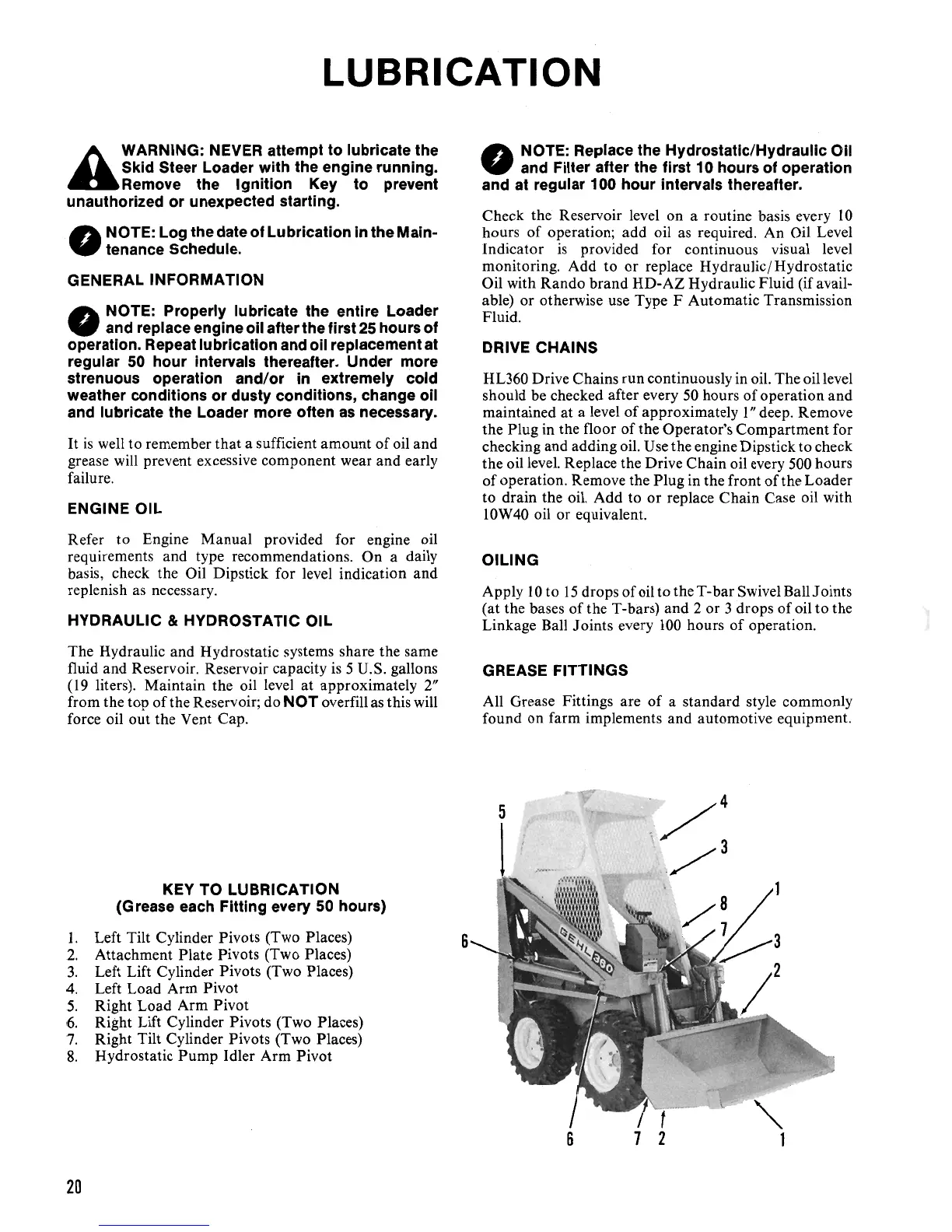

KEY

TO

LUBRICATION

(Grease each Fitting every 50 hours)

1.

Left Tilt Cylinder Pivots (Two Places)

2.

Attachment Plate Pivots (Two Places)

3.

Left Lift Cylinder Pivots (Two Places)

4.

Left Load Arm Pivot

5.

Right Load Arm Pivot

6. Right Lift Cylinder Pivots (Two Places)

7.

Right Tilt Cylinder Pivots (Two Places)

8.

Hydrostatic

Pump

Idler Arm Pivot

and at regular 100 hour intervals thereafter.

Check the Reservoir level on a routine basis every

10

hours

of

operation; add oil as required. An Oil Level

Indicator

is

provided for continuous visual level

monitoring. Add to or replace Hydraulic/ Hydrostatic

Oil with Rando brand HD-AZ Hydraulic Fluid (if avail-

able) or otherwise use Type F Automatic Transmission

Fluid.

DRIVE CHAINS

HL360 Drive Chains run continuously in oil. The oil level

should be checked after every

50

hours of operation

and

maintained

at

a level

of

approximately I" deep. Remove

the Plug in the floor

of

the Operator's Compartment for

checking and adding oil.

V

se

the engine Dipstick to check

the oil level. Replace the Drive Chain oil every

500

hours

of operation. Remove the Plug in the front

of

the Loader

to drain the oil. Add to

or

replace Chain Case oil with

lOW

40 oil or equivalent.

OILING

Apply

10

to

15

drops

of

oil to the T-bar Swivel

Ball]

oints

(at the bases

of

the T -bars) and 2 or 3 drops

of

oil

to

the

Linkage

Ball]

oints every

100

hours of operation.

GREASE

FITTINGS

All Grease Fittings are

of

a standard style commonly

found on farm implements and automotive equipment.

5

6

6 7

20

Loading...

Loading...