ADJ

U

STME

NTS

Simplicity

of

HL360 design and functions makes for a

A

WARNING: The above procedure

for

raising

minimum

amount

of

readjustment required to maintain

the Loader should only

be

used for

ju

st

that.

proper Loader operation.

DO

NOT

leave the Operator's Compartment

NOTE:

If

the Loader

is

operated

on

a "day-to-

•

day" basis and since

NO

gasoline gauge

is

provided, it

is

advisable to refuel before starting the

day.

A

WARNING: Refuel

in

a safe place away from

open flames and potential sparks. NEVER

refuel the Loader while the engine

is

running

or when it

is

HOT.

ENGINE

All information related

to

engine adjustments and

operating settings

is

detailed in the separate Engine

Manual

furnished with the Loader.

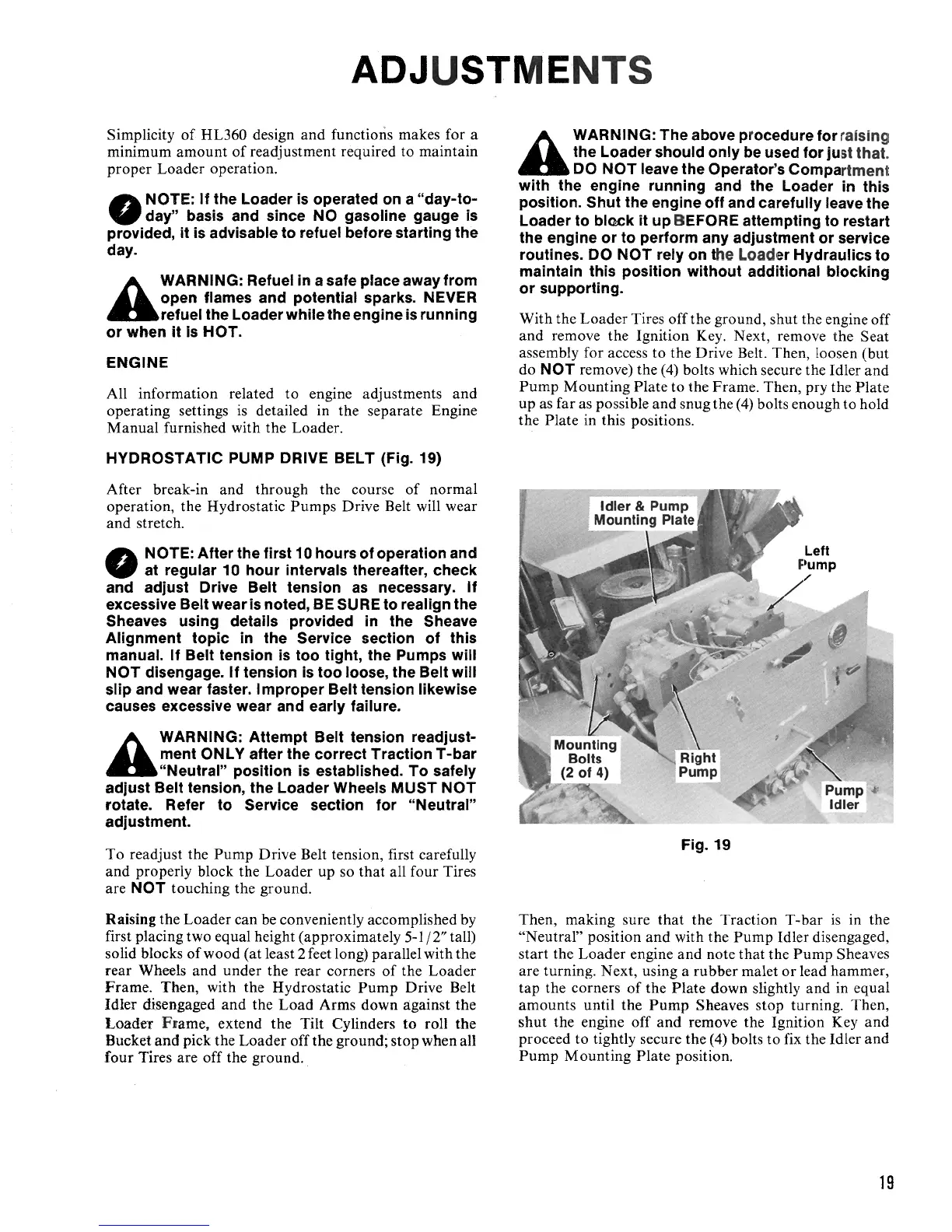

HYDROSTATIC

PUMP

DRIVE BELT (Fig. 19)

After break-in and through the course

of

normal

operation, the Hydrostatic

Pumps

Drive Belt will wear

and stretch .

NOTE: After the first 10 hours of operation and

•

at regular 10 hour intervals thereafter, check

and adjust Drive Belt tension

as

necessary.

If

excessive Belt wear

is

noted,

BE

SU

RE

to

realign the

Sheaves using details provided

in

the Sheave

Alignment topic

in

the Service section of this

manual. If Belt tension

is

too tight, the Pumps will

NOT

disengage. If tension

is

too loose, the Belt will

slip and wear faster. I mproper Belt tension likewise

causes excessive wear and early failure.

A

WARNING: Attempt Belt tension readjust-

ment ONLY after the correct Traction T -bar

"Neutral" position

is

established.

To

safely

adjust Belt tension, the Loader Wheels

MUST

NOT

rotate. Refer to Service section for "Neutral"

adjustment.

To readjust the

Pump

Drive Belt tension, first carefully

and properly block the Loader up so

that

all

four

Tires

are

NOT

touching the ground.

Raising the Loader can

be

conveniently accomplished by

first placing two equal height (approximately

5-1

/

2"

tall)

solid blocks

of

wood (at least 2 feet long) parallel with the

rear Wheels and under the rear corners

of

the Loader

Frame

. Then, with the Hydrostatic

Pump

Drive Belt

Idler disengaged

and

the

Load

Arms down against the

Loader

Fr

ame, extend the Tilt Cylinders to roll the

Bucket and pick the Loader off the ground; stop when all

four

Tires are off the ground.

with the engine running and the Loader

in

this

position. Shut the engine off and carefully leave the

Loader to block it up BEFORE attempting

to

restart

the engine or to perform any adjustment or service

routines. DO

NOT

rely on the Loader Hydraulics to

maintain this position without additional blocking

or supporting.

With the Loader Tires off the ground, shut the engine off

and remove the Ignition Key. Next, remove the Seat

assembly for access to the Drive Belt. Then, loosen (but

do

NOT

remove) the (4) bolts which secure the Idler and

Pump

Mounting Plate to the

Frame

. Then, pry the Plate

up as far as possible and snug the

(4)

bolts enough to hold

the Plate in this positions.

Fig. 19

Then, making sure

that

the Traction T-bar

is

in the

"Neutral" position

and

with the

Pump

Idler disengaged,

start the Loader engine and note

that

the

Pump

Sheaves

are turning. Next, using a rubber malet

or

lead hammer,

tap the corners

of

the Plate down slightly and in equal

amounts until the

Pump

Sheaves stop turning. Then,

shut

the engine off and remove the Ignition Key and

proceed to tightly secure the (4) bolts to fix the Idler and

Pump

Mounting Plate position.

19

Loading...

Loading...