SERVICE

A

WARNING: Perform

all

loader

Service

routines with the engine shut off, except

where noted within certain procedures

outlined.

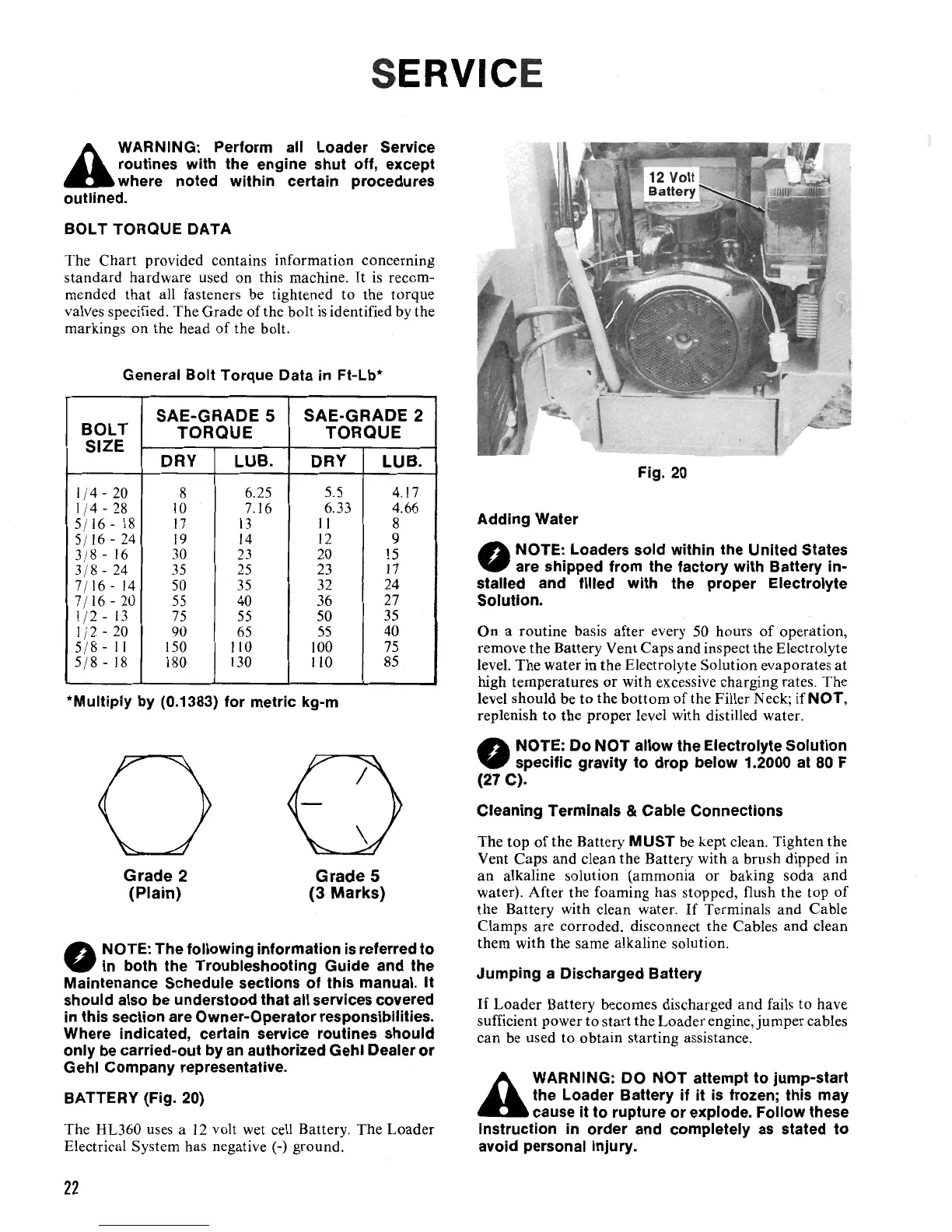

BOLT TORQUE DATA

The

Chart

provided contains information concerning

standard

hardware used on this machine.

It

is

recom-

mended

that

all fasteners be tightened to the torque

valVes

specified. The Grade

of

the bolt

is

identified by the

markings on the head

of

the bolt.

General Bolt Torque Data

in

Ft-lb*

SAE-GRADE 5

SAE-GRADE 2

BOLT

TORQUE TORQUE

SIZE

DRY LUB.

DRY LUB.

1/4 -

20

8

6.25

5.5 4.17

1/4 -

28

10

7.

16

6.33 4.66

5/16

-

18

17

13

II 8

5/

16

-

24

19

14

12

9

3/8 -

16

30

23

20

15

3! 8 -

24

35

25

23

17

7/16-14

50

35

32

24

7/

16

-

20

55

40

36

27

1/2 -

13

75

55

50

35

1/2 -

20

90

65

55

40

5/8 - II

150 110

100

75

5/ 8 -

18

180

130

110

85

*Multiply

by

(0.1383) for metric kg-m

Grade

2

Grade

5

(Plain)

(3

Marks)

O

NOTE: The following information

is

referred

to

in

both the Troubleshooting Guide and the

Maintenance Schedule sections of this manual. It

should

also

be

understood that all services covered

in

this

section are Owner-Operator responsibilities.

Where indicated, certain service routines should

only

be

carried-out

by

an

authorized Gehl Dealer or

Gehl Company representative.

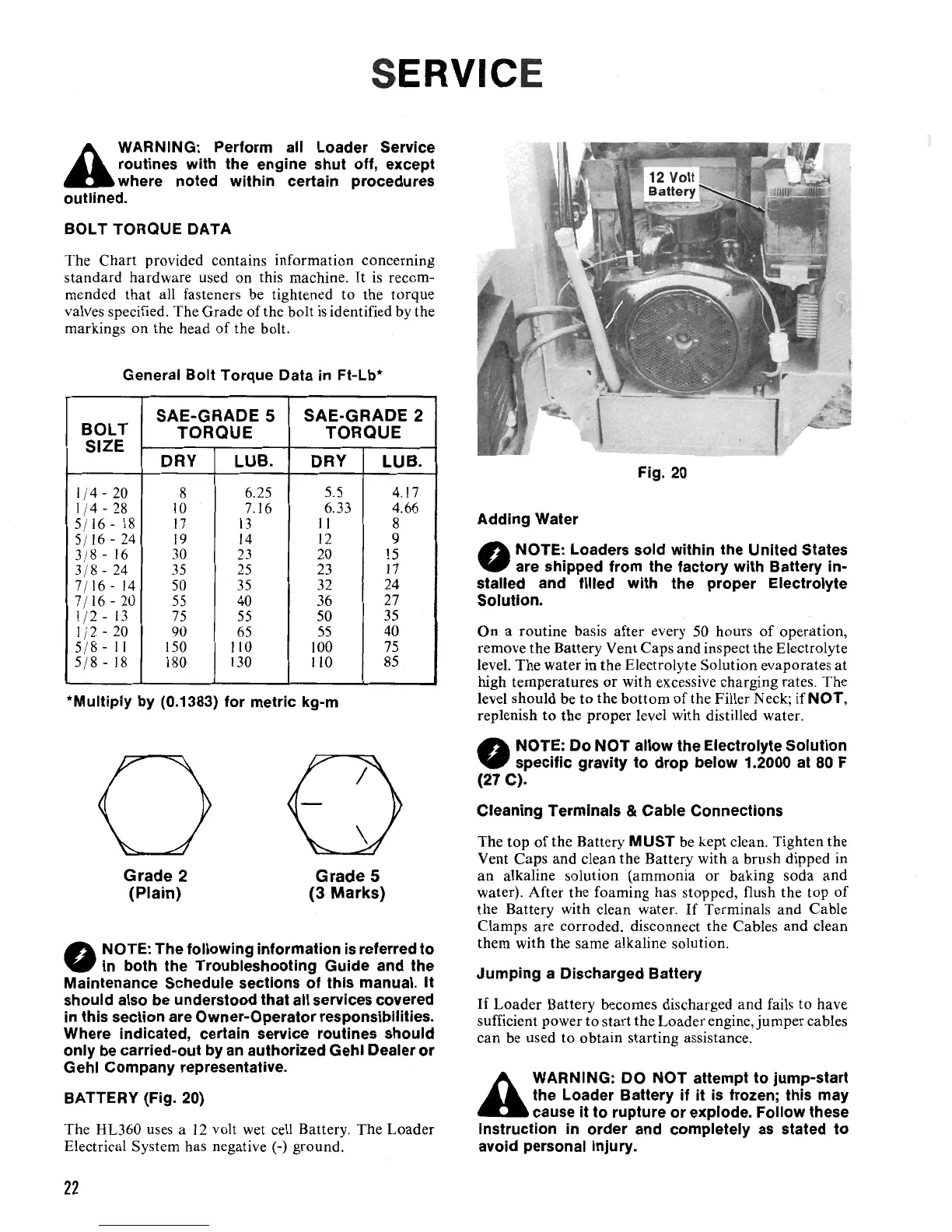

BATTERY (Fig.

20)

Fig. 20

Adding Water

O

NOTE: loaders sold within

th

.e United States

are shipped

from

the factory with Battery in-

stalled and filled with the proper Electrolyte

Solution.

On

a routine basis after every

50

hours

of

operation,

remove the Battery Vent Caps

and

inspect the Electrolyte

level. The water

in

the

Electrolyte Solution evaporates

at

high temperatures

or

with excessive charging rates.

The

level should be

to

the

bottom

of

the Filler Neck; if NOT,

replenish

to

the

proper

level with distilled water.

O

NOTE: Do

NOT

allow the Electrolyte Solution

specific gravity to drop below

1.2000

at

80 F

(27 C).

Cleaning Terminals &Cable Connections

The

top

of

the Battery MUST be kept clean. Tighten

the

Vent Caps

and

clean the Battery with a brush dipped in

an alkaline solution

(ammonia

or baking soda

and

water). After the foaming has stopped, flush the

top

of

the Battery with clean water.

If

Terminals

and

Cable

Clamps are corroded, disconnect the Cables and clean

them with the same alkaline solution.

Jumping a Discharged Battery

If

Loader

Battery becomes discharged and fails to have

sufficient power

to

start the

Loader

engine,

jumper

cables

can

be used

to

obtain starting assistance.

A

WARNING: DO

NOT

attempt

to

jump-start

the

loader

Battery if it

is

frozen; this may

cause

it

to

rupture

or

explode. Follow these

The HL360 uses a

12

volt wet cell Battery. The

Loader

instruction

in

order and completely

as

stated to

Electrical System has negative (-) ground.

avoid personal injury.

22

Loading...

Loading...