NOTE:

BE SURE

thatthejumperbattery

is also

. a 12 volt battery.

•

1.

Turn

off both ignition keys before making

jumper

cable connections.

2.

Make sure

that

both vehicles are in neutral

and

NOT

touching each other.

3.

Remove the Filler Caps from

both

batteries

and

check and replenish the Electrolyte levels before

proceeding.

4.

Place a clean cloth over the uncapped Vent Holes

of

both

batteries

to

prevent boil-over and acid splash.

A

WARNING: If acid contacts your skin, eyes

or clothing, flush the area immediately with

large amounts of water.

5.

Interconnect the positive terminals (+)

of

both

batteries with one

jumper

cable.

6.

Interconnect the negative terminal

of

the booster

battery to

an

unpainted portion

of

the

Loader

Frame

or

engine block.

NOTE:

Twist the jumper cable clamps a couple

•

of times to make a good electrical contact.

DO

NOT

short the jumper cables or cross them.

The

negative

(-)

jumper cable connection should

NOT

be made directly to the Loader Battery to insure that

potential sparks are kept well away from the open

Filler Caps on the discharged Battery which will

tend to produce hydrogen gas.

7.

Proceed to start the Loader.

If

it does

NOT

start im-

mediately, start the engine

of

the booster vehicle to

avoid excessive drain on the booster battery.

8.

After the Loader

is

started

and

running smoothly,

remove the

jumper

cable from the Loader

Frame

member first. Then, detach the opposite end from

the booster battery. Then, remove the other

jumper

cable from the booster battery and the Loader

positive

(+) Terminal. .

Allow the Loader

to

recharge the Battery for approxi-

mately

10

minutes before attempting to operate the

Loader.

BE SURE

to

discard the cloths and replace the

Vent Caps on both batteries .

NOTE:

If Loader Battery discharging becomes

•

a reoccurring problem, have Battery checked

for possible dead cell

and/or

troubleshoot Electrical

System for possible shorted wire or damaged

insulation.

Recharging Weak Battery

If

Loader Battery becomes run-down

and

weak, it may be

desirable

to

recharge it with a plug-in 120 volt

AC

battery

charger unit. Follow operating instructions given with re-

charger unit and exercise all prescribed precautions.

BE

SURE

also to remove the

Loader

Battery Vent Caps

and

cover the uncapped Vent Holes and check the Electrolyte

level before starting the charger.

A

WARNING:

DO

NOT

attempt to recharge a

frozen Battery; this may cause it to rupture

or explode.

DO

NOT

attempt to recharge the

Battery in an area of sparks or near

an

open flame.

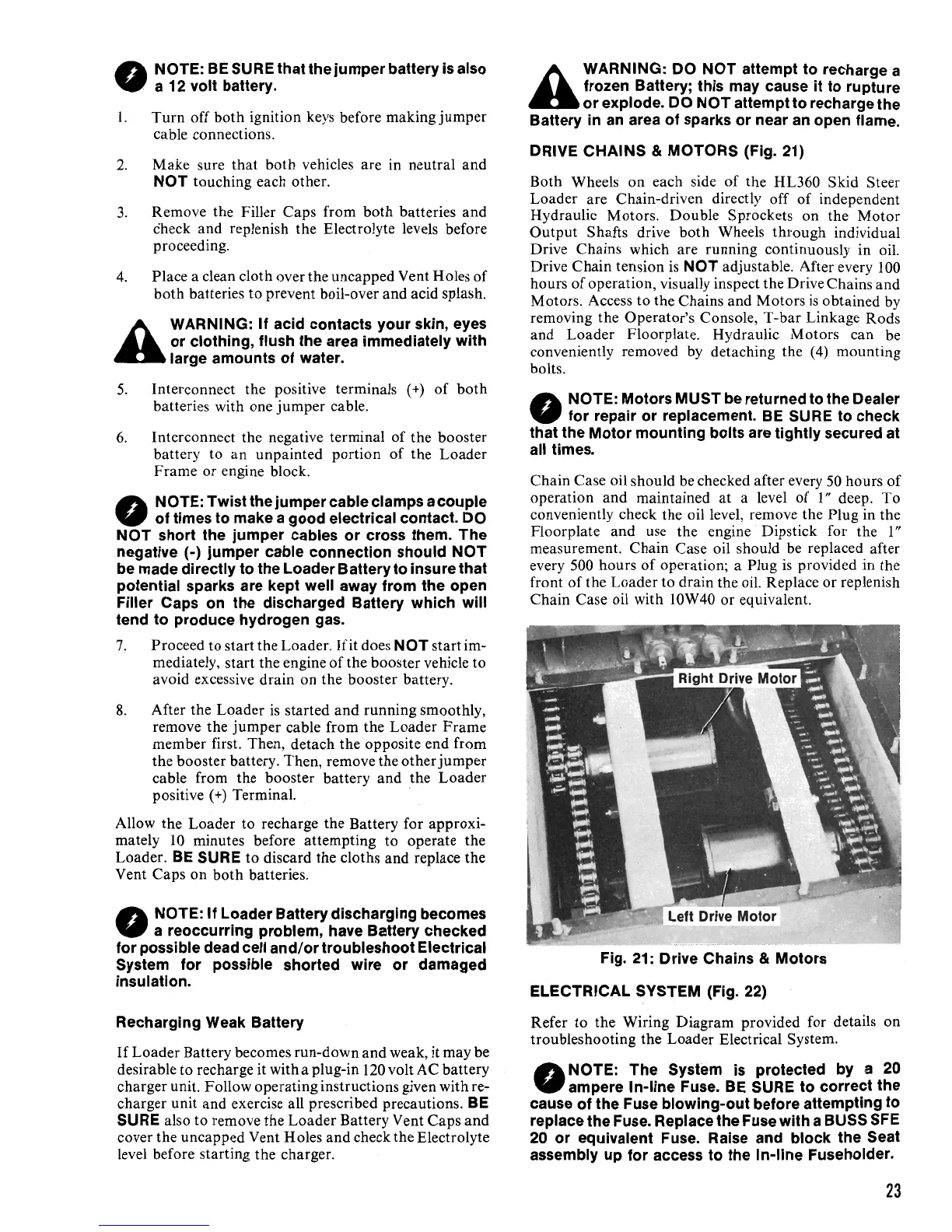

DRIVE

CHAINS

&

MOTORS

(Fig. 21)

Both Wheels

on

each side

of

the HL360 Skid Steer

Loader are Chain-driven directly off

of

independent

Hydraulic Motors. Double Sprockets on the

Motor

Output

Shafts drive

both

Wheels through individual

Drive Chains which are running continuously in oil.

Drive Chain tension

is

NOT

adjustable. After every

100

hours

of

operation, visually inspect the Drive Chains and

Motors. Access

to

the Chains and Motors

is

obtained by

removing the Operator's Console, T-bar Linkage Rods

and

Loader Floorplate. Hydraulic Motors can be

conveniently removed by detaching the (4) mounting

bolts.

NOTE:

Motors

MUST

be returned to the Dealer

•

for repair or replacement. BE SURE to check

that

the

Motor

mounting bolts are tightly secured at

all times.

Chain Case oil should be checked after every 50 hours

of

operation and maintained at a level

of

1"

deep.

To

conveniently check the oil level, remove the Plug in the

Floorplate and use the engine · Dipstick for the

1"

measurement. Chain Case oil should be replaced after

every 500 hours

of

operation; a Plug

is

provided in the

front

of

the Loader to drain the oil. Replace

or

replenish

Chain Case oil with lOW40 or equivalent.

Fig. 21: Drive Chains & Motors

ELECTRICAL

SYSTEM (Fig. 22)

Refer to the Wiring Diagram provided for details on

troubleshooting the Loader Electrical System.

NOTE:

The

System

is

protected

by

a 20

•

ampere In-line Fuse. BE SURE to correct the

cause of the Fuse blowing-out before attempting to

replace the Fuse. Replace the Fuse with a BUSS SFE

20 or equivalent Fuse. Raise and block the Seat

assembly up for access to the In-line Fuseholder.

23

Loading...

Loading...