50960066/AP0813 50 PRINTED IN U.S.A.

Inflate as necessary per the chart below:

12-16.5 NHS 10 PR: 65 psi (450 kPa)

NOTE: If the tires have been filled with water or

calcium chloride for ballast, a calcium chloride tire

pressure gauge MUST be used to check the tire

pressure.

To ensure proper load carrying capability, original

equipment tires comply with the specifications pub-

lished in the Tire and Rim Association Yearbook.

Replacement tires MUST meet the same specifica-

tions. When replacing tires, be sure all tires are of the

same type, quality and load rating, and the same size as

the original equipment. When removing tires, follow

industry safety practices. Deflate completely prior to

removal. After assembly of the tire on the rim, use a

safety cage or restraining device while inflating.

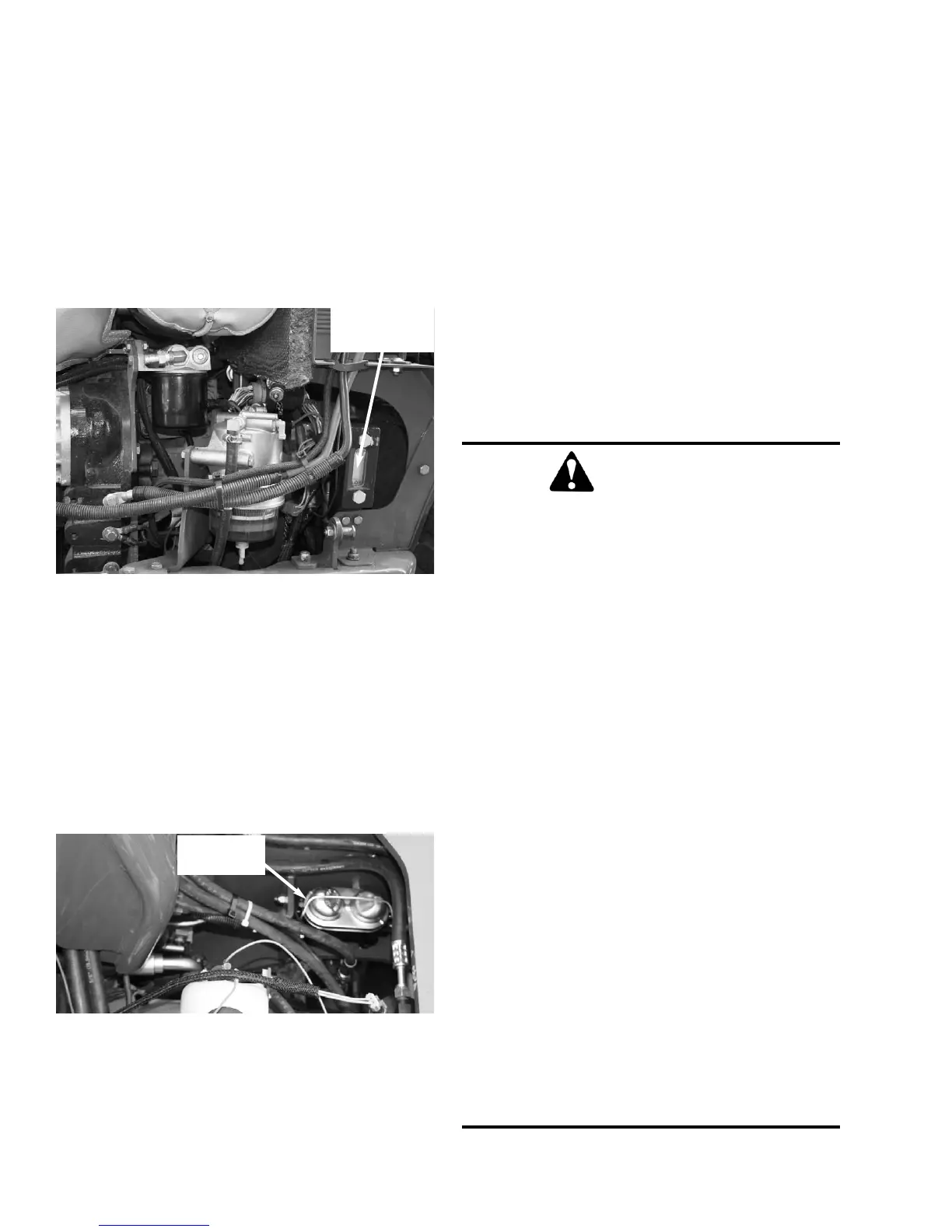

CHECKING HYDRAULIC OIL LEVEL

The machine must be on level ground with boom low-

ered and completely retracted. The fluid MUST be cool

when checking the reservoir level, to reduce the possi-

bility of overfilling the hydraulic system.

Open the right side engine cover and locate the sight

gauge below the battery compartment. The oil level

should be at the midpoint of the sight gauge. If the oil

level is down, or below the sight gauge, fill with the

required amount of oil. See the Lubrication chapter for

the type of oil to use.

IMPORTANT: Be careful when removing the

reservoir filler cap so that no dirt or other foreign

matter enters the hydraulic system. DO NOT

OVERFILL.

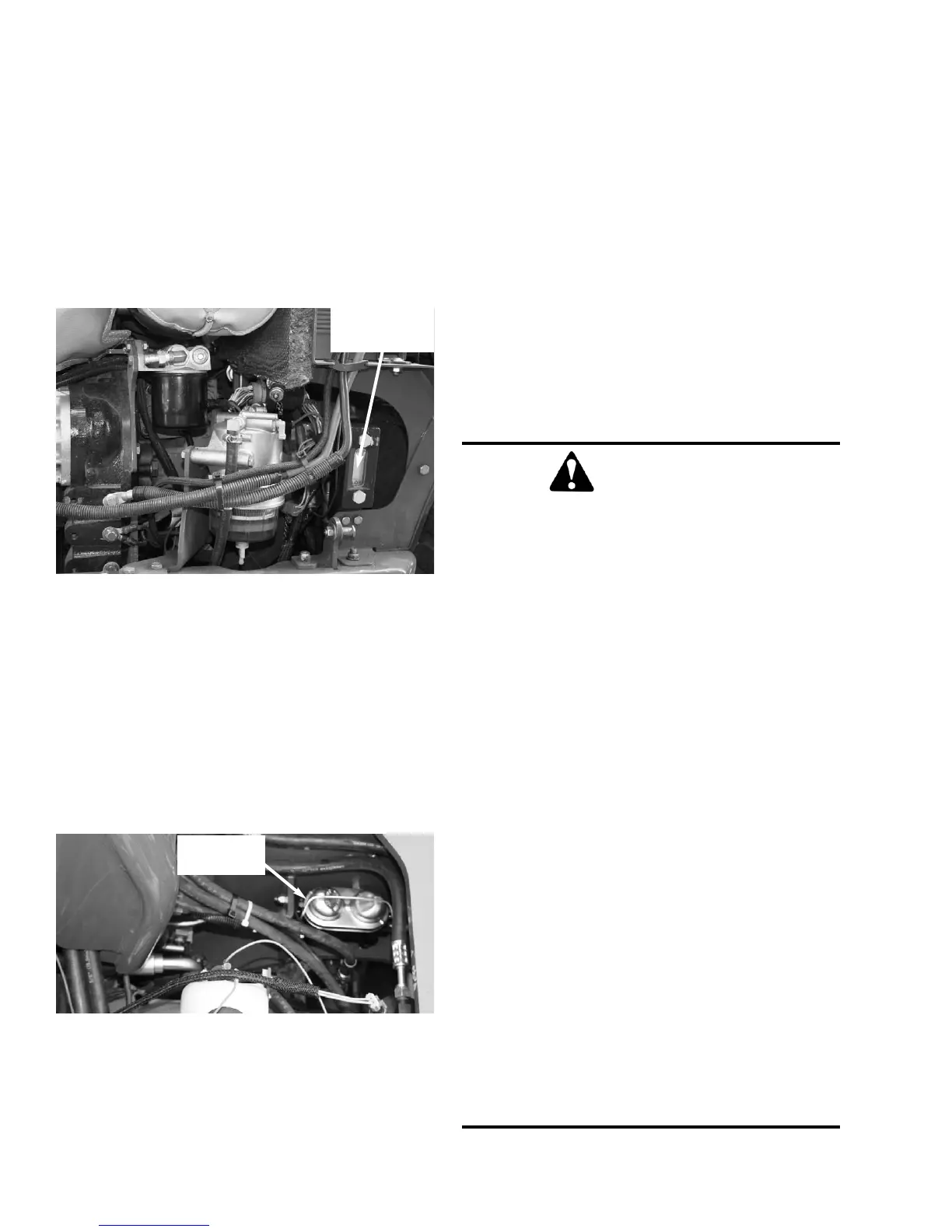

CHECKING BRAKE RESERVOIR

LEVEL

Remove the cover on the front of the frame. Remove

the reservoir cover to check the fluid level. If low, fill

to the proper level with the correct fluid. See the

Lubrication chapter for the type of fluid to use.

CHECKING TIRE PRESSURES

To ensure proper operating stability and extend tire

life, proper and equal tire pressure should be main-

tained in all four tires. Check tire pressures “cold.”

WARNING

Inflating or servicing tires can be dangerous.

Whenever possible, trained personnel should

service and mount tires. To avoid possible

death or serious injury, follow the safety pre-

cautions below:

1. BE SURE the rim is clean and free of rust.

2. Lubricate both the tire beads and rim

flanges with a soap solution. DO NOT use

oil or grease.

3. DO NOT place your fingers on the tire bead

or rim during inflation. Use a clip-on tire

chuck with a remote hose and gauge,

which allows you to stand clear of the tire

while inflating it.

4. NEVER inflate beyond 35 psi (240 kPa) to

seat the beads. If the beads have not seat-

ed by the time the pressure reaches 35 psi

(240 kPa), deflate the assembly, reposition

the tire on the rim, relubricate both parts

and re-inflate. Inflation pressure beyond 35

psi (240 kPa) with unseated beads may

break the bead or rim with explosive force

sufficient to cause death or serious injury.

5. After seating the beads, adjust the inflation

pressure to the recommended operating

pressure listed.

6. DO NOT weld, braze, or otherwise attempt

to repair and use a damaged rim.

Brake Fluid

Reservoir

Hydraulic Oil

Sight Gauge

Loading...

Loading...