913218/CP0307 32 PRINTED IN U.S.A.

Engine Coolant Temperature

There are two coolant temperature features: High

Coolant Temperature WARNING, and High Coolant

Temperature SHUTDOWN.

At the High Coolant Temperature WARNING set-

point, the warning lamp in the engine override switch

will flash and a slow engine power derate will begin.

But if the coolant temperature drops below the High

Coolant Temperature WARNING set-point, the power

will increase slowly until the engine is back to full

power. The lamp will continue to flash until the power

has returned to normal even if the fault condition has

been corrected and the recovery is in process.

At the High Coolant Temperature SHUTDOWN set-

point, the lamp in the engine override switch will light

continously, and a fast engine power derate will begin.

If the coolant temperature does not drop below the

SHUTDOWN set-point within 30 seconds, the engine

will shut down. Howerver, if the coolant temperature

drops below the High Coolant Temperature SHUT-

DOWN set-point within 30 seconds, then the power

derate speed will revert to the High Coolant

Temperature WARNING speed of reaction.

PARKING BRAKE

NOTE: The parking brake mechanism within the

front axle is NOT designed for, OR intended to be

used as, the primary means of stopping move-

ment of the machine. Hydraulic braking provided

through the service brakes within the axles is the

primary means for stopping movement. The axle-

by-axle split brake system is the secondary

means of stopping movement.

The proper sequence for correct machine operation is

to always engage the parking brake switch before shut-

ting off the engine; and to disengage the parking brake

ONLY after the engine is running. In an EMER-

GENCY, if it becomes necessary to STOP movement,

activate the parking brake switch to “ON.”

CHANGING ATTACHMENT TOOLS

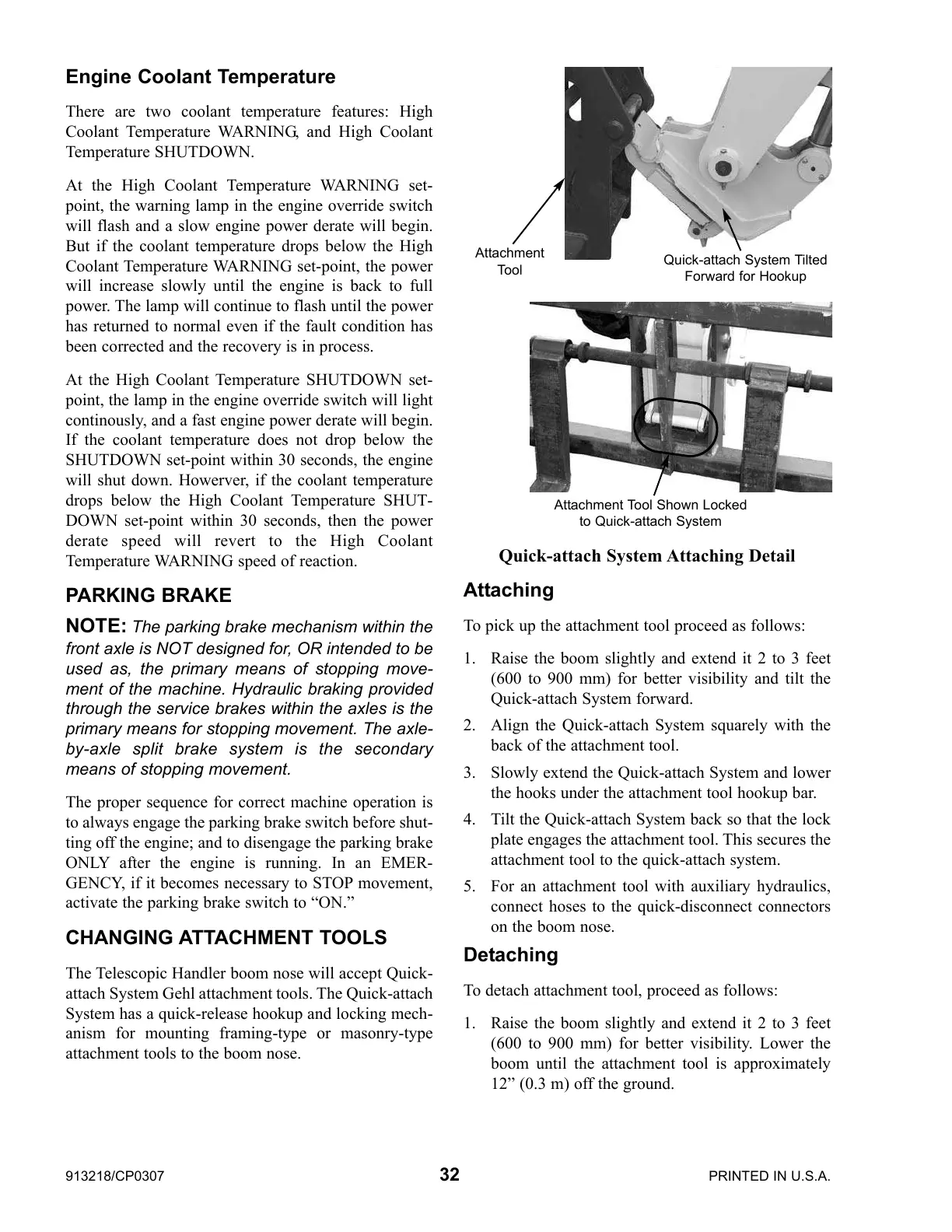

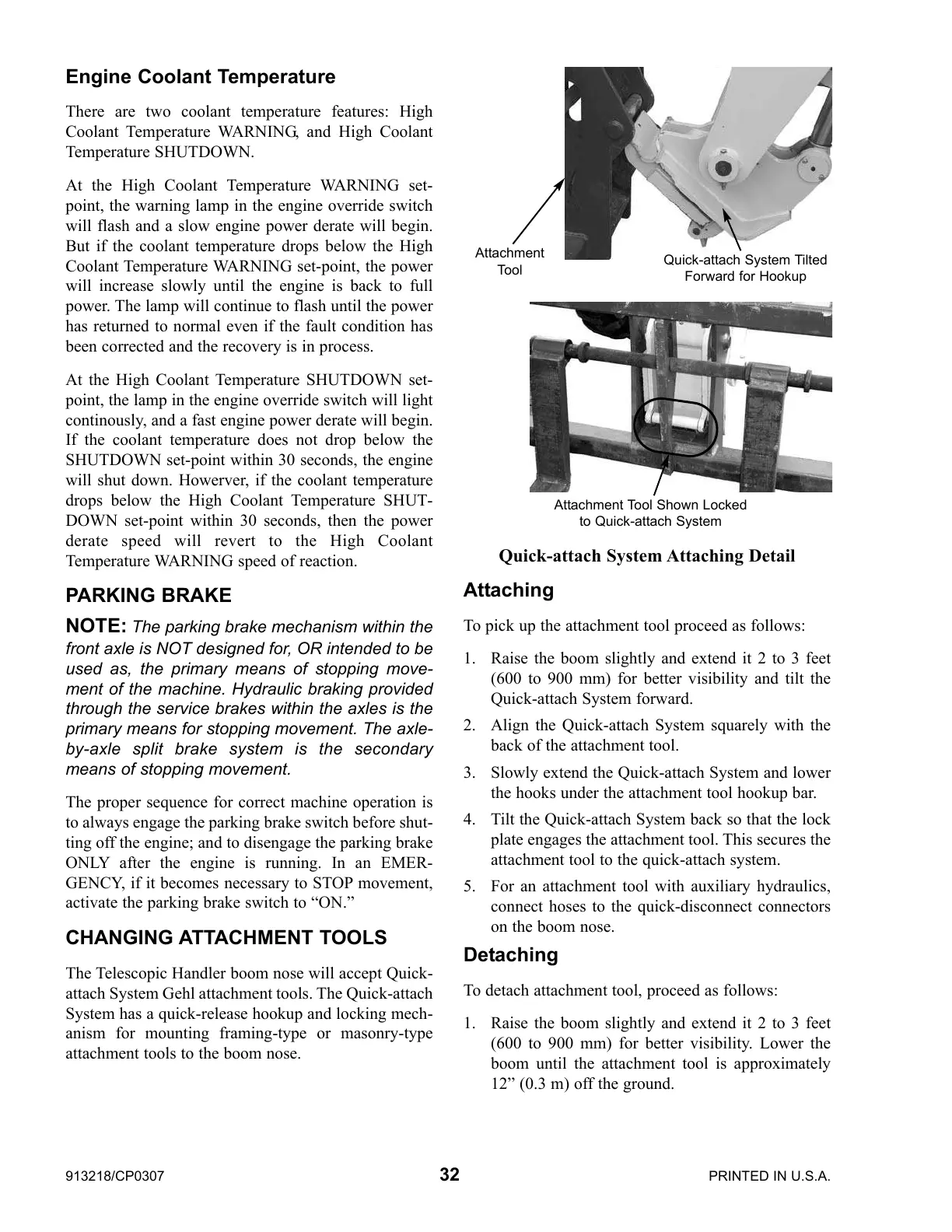

The Telescopic Handler boom nose will accept Quick-

attach System Gehl attachment tools. The Quick-attach

System has a quick-release hookup and locking mech-

anism for mounting framing-type or masonry-type

attachment tools to the boom nose.

Attaching

To pick up the attachment tool proceed as follows:

1. Raise the boom slightly and extend it 2 to 3 feet

(600 to 900 mm) for better visibility and tilt the

Quick-attach System forward.

2. Align the Quick-attach System squarely with the

back of the attachment tool.

3. Slowly extend the Quick-attach System and lower

the hooks under the attachment tool hookup bar.

4. Tilt the Quick-attach System back so that the lock

plate engages the attachment tool. This secures the

attachment tool to the quick-attach system.

5. For an attachment tool with auxiliary hydraulics,

connect hoses to the quick-disconnect connectors

on the boom nose.

Detaching

To detach attachment tool, proceed as follows:

1. Raise the boom slightly and extend it 2 to 3 feet

(600 to 900 mm) for better visibility. Lower the

boom until the attachment tool is approximately

12” (0.3 m) off the ground.

Quick-attach System Attaching Detail

Attachment Tool Shown Locked

to Quick-attach System

Quick-attach System Tilted

Forward for Hookup

Attachment

Tool

Loading...

Loading...