913218/CP0307 54 PRINTED IN U.S.A.

CHECKING AND TORQUING BOOM LEAF

CHAINS

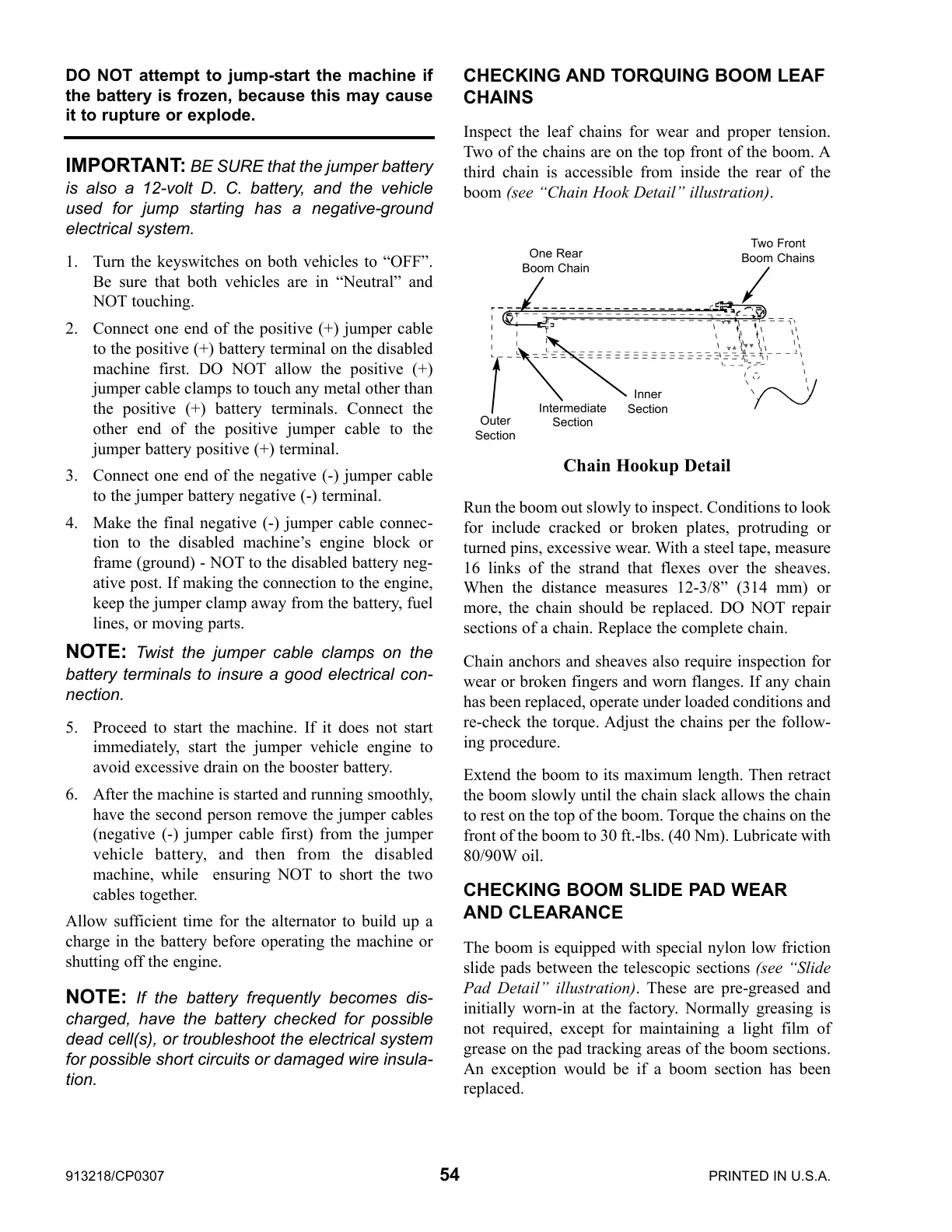

Inspect the leaf chains for wear and proper tension.

Two of the chains are on the top front of the boom. A

third chain is accessible from inside the rear of the

boom (see “Chain Hook Detail” illustration).

Run the boom out slowly to inspect. Conditions to look

for include cracked or broken plates, protruding or

turned pins, excessive wear. With a steel tape, measure

16 links of the strand that flexes over the sheaves.

When the distance measures 12-3/8” (314 mm) or

more, the chain should be replaced. DO NOT repair

sections of a chain. Replace the complete chain.

Chain anchors and sheaves also require inspection for

wear or broken fingers and worn flanges. If any chain

has been replaced, operate under loaded conditions and

re-check the torque. Adjust the chains per the follow-

ing procedure.

Extend the boom to its maximum length. Then retract

the boom slowly until the chain slack allows the chain

to rest on the top of the boom. Torque the chains on the

front of the boom to 30 ft.-lbs. (40 Nm). Lubricate with

80/90W oil.

CHECKING BOOM SLIDE PAD WEAR

AND CLEARANCE

The boom is equipped with special nylon low friction

slide pads between the telescopic sections (see “Slide

Pad Detail” illustration). These are pre-greased and

initially worn-in at the factory. Normally greasing is

not required, except for maintaining a light film of

grease on the pad tracking areas of the boom sections.

An exception would be if a boom section has been

replaced.

IMPORTANT: BE SURE that the jumper battery

is also a 12-volt D. C. battery, and the vehicle

used for jump starting has a negative-ground

electrical system.

1. Turn the keyswitches on both vehicles to “OFF”.

Be sure that both vehicles are in “Neutral” and

NOT touching.

2. Connect one end of the positive (+) jumper cable

to the positive (+) battery terminal on the disabled

machine first. DO NOT allow the positive (+)

jumper cable clamps to touch any metal other than

the positive (+) battery terminals. Connect the

other end of the positive jumper cable to the

jumper battery positive (+) terminal.

3. Connect one end of the negative (-) jumper cable

to the jumper battery negative (-) terminal.

4. Make the final negative (-) jumper cable connec-

tion to the disabled machine’s engine block or

frame (ground) - NOT to the disabled battery neg-

ative post. If making the connection to the engine,

keep the jumper clamp away from the battery, fuel

lines, or moving parts.

NOTE: Twist the jumper cable clamps on the

battery terminals to insure a good electrical con-

nection.

5. Proceed to start the machine. If it does not start

immediately, start the jumper vehicle engine to

avoid excessive drain on the booster battery.

6. After the machine is started and running smoothly,

have the second person remove the jumper cables

(negative (-) jumper cable first) from the jumper

vehicle battery, and then from the disabled

machine, while ensuring NOT to short the two

cables together.

Allow sufficient time for the alternator to build up a

charge in the battery before operating the machine or

shutting off the engine.

NOTE: If the battery frequently becomes dis-

charged, have the battery checked for possible

dead cell(s), or troubleshoot the electrical system

for possible short circuits or damaged wire insula-

tion.

Chain Hookup Detail

Inner

Section

Outer

Section

Intermediate

Section

Two Front

Boom Chains

One Rear

Boom Chain

DO NOT attempt to jump-start the machine if

the battery is frozen, because this may cause

it to rupture or explode.

Loading...

Loading...