PRINTED IN U.S.A. 55 913218/CP0307

transmission oil. Shut down the engine. Access to filter

and drain plug is from underneath the machine.

Proceed as follows:

1. Remove the drain plug and drain old oil. Replace

the drain plug.

IMPORTANT: DO NOT discharge oil onto

ground. Catch and dispose of per local waste dis-

posal regulations.

2. Remove and discard the oil filter. Wipe the sealing

surface on the transmission with a clean cloth.

Apply a thin coat of clean oil to the new oil filter

gasket. Hand tighten.

3. Refill the transmission with new oil as shown in

the LUBRICATION chapter of this manual.

IMPORTANT: DO NOT OVERFILL! lf the oil

level is too high, oil foaming, excessively high oil

temperature and oil leakage at the seals could

result.

4. Start and run the machine long enough for the oil

to circulate and warm slightly. Recheck the level

with the dipstick.

CHANGING RADIATOR COOLANT

Drain, flush and refill the cooling system as follows:

IMPORTANT: DO NOT discharge coolant onto

ground. Catch and dispose of per local waste dis-

posal regulations.

1. Loosen the radiator cap to its stop. This will

release any system pressure. Remove the cap when

all pressure is bled off.

2. Open the radiator drain cock. Remove the water

jacket drain plug from the engine block. When all

coolant is drained, flush the system with clean

fresh water. Allow the flush to drain completely.

3. Replace all drain plugs and tighten the radiator

drain cock. Clean the cooling fins in the radiator

with water pressure or steam.

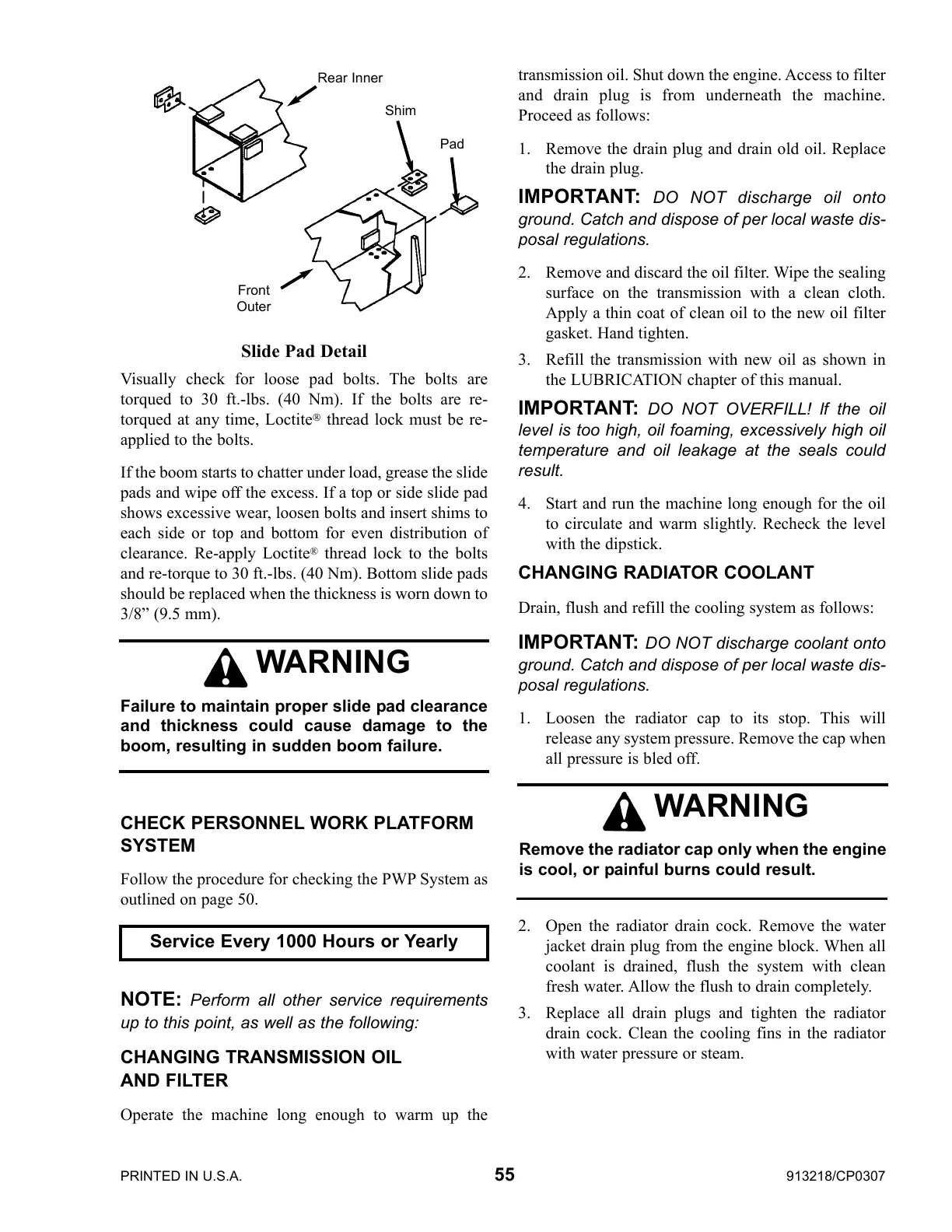

Visually check for loose pad bolts. The bolts are

torqued to 30 ft.-lbs. (40 Nm). If the bolts are re-

torqued at any time, Loctite

thread lock must be re-

applied to the bolts.

If the boom starts to chatter under load, grease the slide

pads and wipe off the excess. If a top or side slide pad

shows excessive wear, loosen bolts and insert shims to

each side or top and bottom for even distribution of

clearance. Re-apply Loctite

®

thread lock to the bolts

and re-torque to 30 ft.-lbs. (40 Nm). Bottom slide pads

should be replaced when the thickness is worn down to

3/8” (9.5 mm).

CHECK PERSONNEL WORK PLATFORM

SYSTEM

Follow the procedure for checking the PWP System as

outlined on page 50.

NOTE: Perform all other service requirements

up to this point, as well as the following:

CHANGING TRANSMISSION OIL

AND FILTER

Operate the machine long enough to warm up the

WARNING

Remove the radiator cap only when the engine

is cool, or painful burns could result.

Service Every 1000 Hours or Yearly

Slide Pad Detail

Rear Inner

Shim

Pad

Front

Outer

WARNING

Failure to maintain proper slide pad clearance

and thickness could cause damage to the

boom, resulting in sudden boom failure.

Loading...

Loading...