210 ONE MAN HOLE DIGGER, FORM GOM-1061-1189, VERSION 2.0, AUTHORIZATION: DVR, PAGE: 15

becomes fully disengaged with no horsepower and

torque is being transmitted to the auger. In the slipping

mode, a centrifugal clutch still transmits a specific

amount of horsepower and torque to the auger. This

specific amount of horsepower and torque directly

proportional to many factors including: the mechanical

condition of the centrifugal clutch assembly and the

rotational speed of the centrifugal clutch assembly

when the initial slippage occurs. The response time for

the centrifugal clutch assembly to react to an overload

condition is directly proportional to its rotational speed.

The higher the rotational speed (RPM) of the

centrifugal clutch at the time of overload, the greater

amount of time it requires to react and actually slip.

This phenomenon is inherent with all centrifugal clutch

assemblies. It is also inherent with all powered

equipment incorporating such a device.

STRIKING BURIED OBSTRUCTIONS SUCH AS

TREE ROOTS, ROCKS AND OTHER DEBRIS AT

ANY SPECIFIC ENGINE OPERATING SPEED CAN

CAUSE THE HOLE DIGGER TO TRANSMIT

REACTIONARY TYPE "IMPACT" LOADS TO THE

OPERATOR. THESE TYPES OF LOADS ARE

CHARACTERIZED BY A SHARP, PULSATING

MOVEMENT OF THE HOLE DIGGER IN A

COUNTERCLOCKWISE DIRECTION (AS VIEWED

BY THE OPERATOR). SUCH LOADS CAN LEAD TO

THE LOSS OF OPERATOR CONTROL AND RESULT

IN PERSONAL INJURY. THE OPERATIONAL

EFFECTS ARE ALIKE TO THAT OF UTILIZING A

COMMON ELECTRIC DRILL AND OTHER,

ROTATION TYPE, POWERED EQUIPMENT. THE

RELATED PHENOMENON IS INHERENT WITH ALL

SUCH TYPES OF ROTATION TYPE, POWERED

EQUIPMENT AND IS TERMED AS KICKBACK.

UNDERSTANDING KICKBACK.

The operation of the Hole Digger involves engine

torque being transmitted and multiplied by the

transmission to the auger. The energy is then used to

dig holes. But to every force (action), there is always a

reaction force in the opposite direction. Thus, if the

auger contacts a buried obstruction, the operator will

feel the left side of the handle of the Hole Digger being

"thrusted" toward him. This "thrusting" force

experienced by the operator is called kickback. The

speed that the handle moves (and magnitude of the

resulting impact force) is directly proportional to the

amount/speed of the kickback force experienced by

the operator. The torque and kickback generated by

the digging process is inherent with a portable, one

man Hole Digger of this type. The operational effects

are alike to that of utilizing a common, electric drill and

other, rotation type, powered tools.

MINIMIZING KICKBACK FROM AN OPERATIONAL

STANDPOINT.

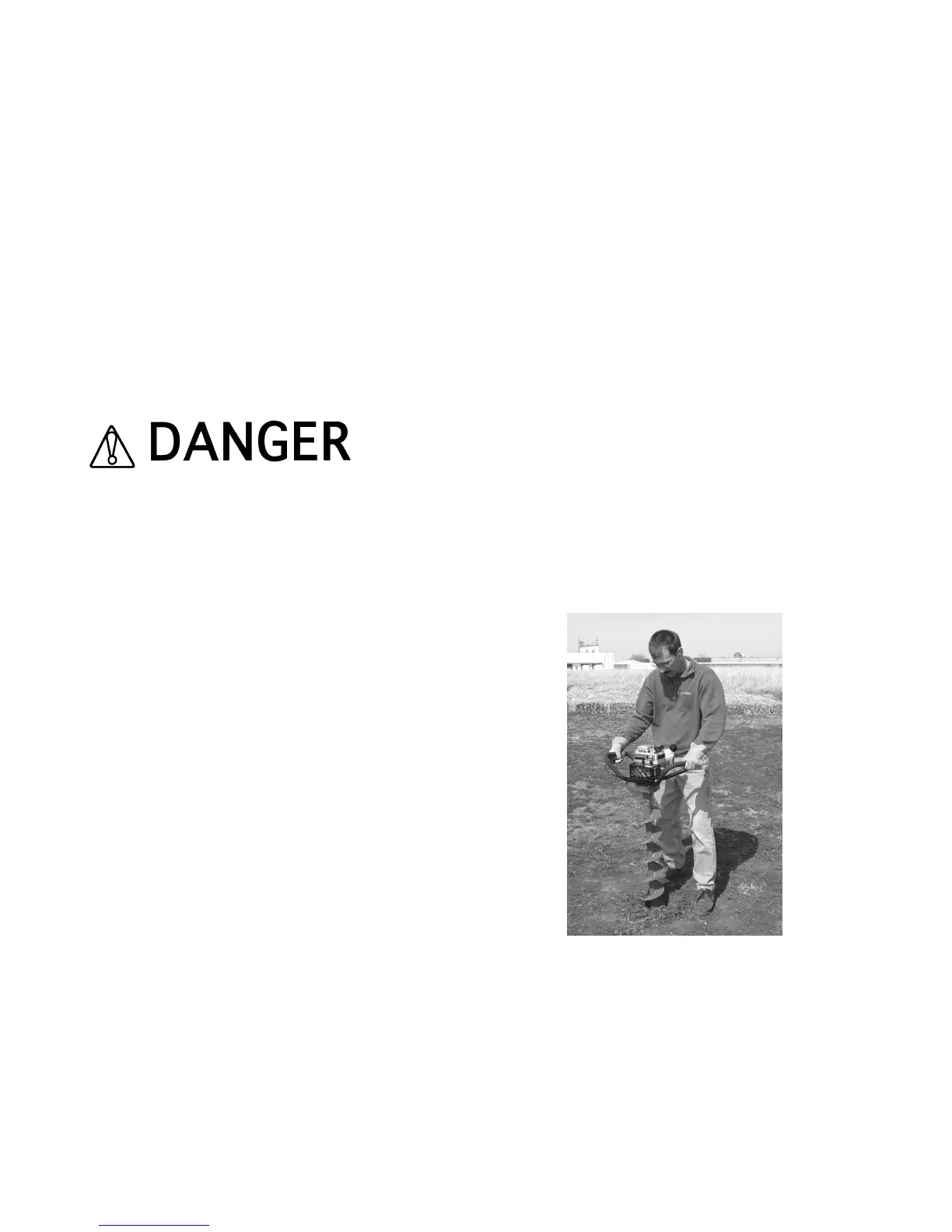

The operator should keep the left side of the handle as

close to his body (left hip and leg areas) as possible to

minimize machine "kickback" when a buried

obstruction is encountered by the auger. Assume

operating positions that allow exercising reactive "body

english" against the torque sensation created by the

digging process. Keep upper arms as close to the

upper body as possible to maximize mechanical

leverage. An operator should position his back as

vertical as possible by bending the legs as required

during the digging process. Positioning the left foot

ahead of the right foot at a confortable distance will

enhance proper body position. Maintaining proper

operating position is one of the most IMPORTANT and

EFFECTIVE procedures for controlling kickback.

Improper operating positions only aggrevate the effects

of kickback upon the operator. FIGURE 8 depicts a

proper operator position. FIGURE 9 depicts an

improper operator position.

FIGURE 8

Loading...

Loading...