Do you have a question about the GEZE Slimdrive SC and is the answer not in the manual?

Read manual carefully and comply with safety instructions for safe operation.

Details glass and framed door leaves compatible with the drive system.

Description of the DC motor, control system, and operational features of the drive.

Weekly safety check list for users to ensure safe operation of powered sliding doors.

Testing of sensors, including activation distance and closing delay.

Testing of presence sensing devices and hold open beams for obstruction detection.

Checks for tripping hazards, glass integrity, signage, and activation controls.

Extracts detailing test procedures, test objects, and frequency from BS 7036.

Details modes like Automatic, Hold Open, Night, and Exit Only for door operation.

Overview of the programme switch functions and indicator lights.

Important notice regarding manual locks and switching drive unit modes.

List of 2-digit fault codes and their descriptions for SL 1.7 to SL 1.9 systems.

List of 2-digit fault codes and their descriptions for SL DCU 1 systems.

Procedure for power failure, battery presence, and manual operation.

Behavior of doors during fire alarm activation in Automatic and Night modes.

Explanation of the service indicator LED and its meaning.

Instructions for cleaning drive unit cover, activation and safety sensors.

Recommendations for preventative maintenance programs and authorized technicians.

Cleaning and care instructions for various door materials including aluminium, steel, and glass.

Commitment to 24/7 service and repair for automatic and manual doors.

Details on warranty period, coverage, and post-warranty service contracts.

Contact information for nationwide assistance and regional GEZE service offices.

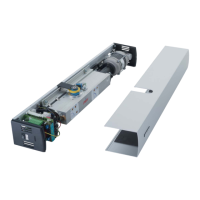

The GEZE Slimdrive SC/SCR, Slimdrive SLT, Slimdrive SL, and EC Drive/Powerdrive are automatic sliding door operators designed for pedestrian use. This manual outlines their operation, safety, and maintenance procedures.

These devices are automatic sliding door drives that facilitate the opening and closing of various types of doors. They are suitable for glass doors (single or double glazed) and doors with timber, metal, or aluminum frames. The core function is to provide automated access, enhancing convenience and managing traffic flow in various environments.

The drive system incorporates a low-wear, high-capacity DC motor and an extremely quiet, enclosed running gear. Power transmission is achieved via toothed belts with precision bearings, ensuring smooth and reliable operation. A self-learning processor control system continuously monitors and adapts to the door's environment. Permanent position sensing of the door leaves is managed by a non-contact distance measuring system, which allows for precise control of door movement. The system can also determine the door leaf weight using an acceleration meter, further optimizing its performance.

Key operational features include an adjustable hold-open time, allowing the door to remain open for a specified duration (typically 1 to 5 seconds). Automatic error detection is built into the system, with error indications displayed on the program switch and an audible signal in case of a fault. Both opening and closing speeds are individually adjustable, and the system automatically adjusts the opening time based on traffic patterns.

For enhanced safety, the doors feature an automatic reversing function with adjustable reversing pressure. If the door encounters an obstacle during closure, it will automatically reopen. An emergency opening function is provided via an integrated battery backup in case of power failure, ensuring egress. An integrated mains isolator is also included for safety during maintenance. The closing force is limited to less than 150 N to prevent injury.

Optional features include a connection to a fire alarm system, allowing the doors to respond appropriately during an emergency. Electro-magnetic locking can be integrated to secure the door leaves against forced entry.

The door's operation is managed through a program switch, which allows users to select different modes of operation, view error messages, and perform programming and service functions.

It is crucial to ensure that any manual locks fitted to the door leaf are UNLOCKED before switching the drive unit into any operational mode. Additionally, the drive unit should be switched to NIGHT MODE before manually locking the door.

In the event of a power failure, the door's behavior depends on the presence of a battery and the selected mode. If a battery is present, the door will typically open unless in Night mode. If the battery is discharged or not present, the door must be unlocked and opened/closed manually. After power is restored, the door automatically returns to its previously selected operating state, or to "Night" mode if it was locked.

If a fire alarm is activated (and the system is fitted with this option), doors in "Automatic" setting will power open and remain fully open until the alarm is reset. Doors in "Night" position will remain closed/locked to maintain security.

Regular maintenance is essential for the continued safe and efficient operation of the GEZE automatic sliding doors. The manual strongly advises implementing a preventative maintenance program in line with BS 7036: Safety at Powered Doors for Pedestrian Use, with servicing carried out by an authorized technician.

The occupier is responsible for undertaking weekly safety tests, or more frequently in high-traffic areas, as per BS 7036: Part 2: 1996 (Annexes).

If any fault affecting safe operation is found, the door operating equipment should be switched off and made safe. Use of the door should not be reinstated until an authorized technician has completed repairs.

A service indicator LED will illuminate when an annual service is required. GEZE provides comprehensive 24-hour nationwide service and offers service contracts based on the recommendation of servicing powered doors twice per year.

| Drive Type | Electromechanical |

|---|---|

| Max Door Weight | 120 kg |

| Power Supply | 230 V AC, 50/60 Hz |

| Hold-open Time | Adjustable |

| Control Options | Push buttons, Motion detectors, Access control systems |

| Safety Devices | Safety light barriers |

| Dimensions | Height: 70 mm |