reverse order.

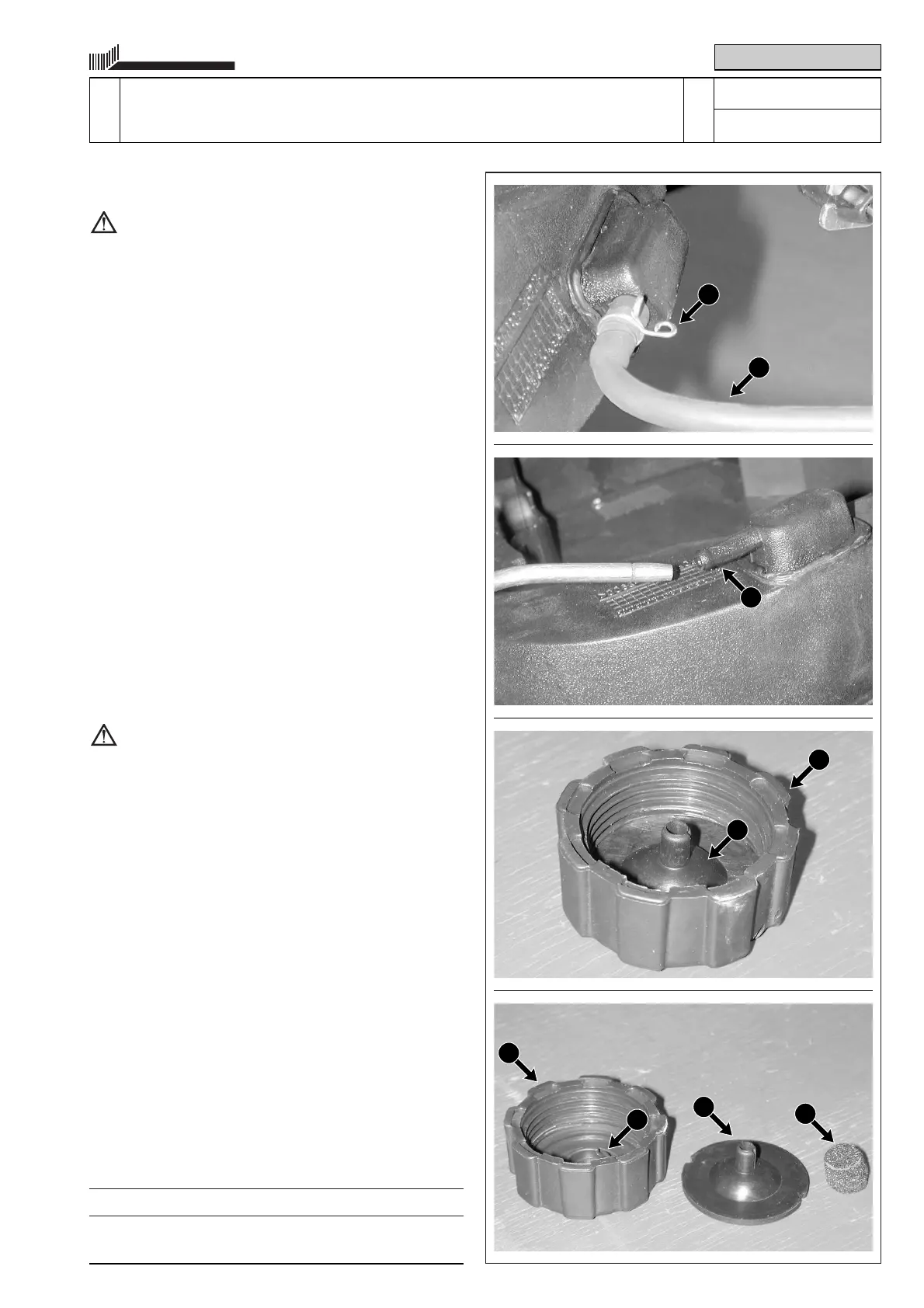

WARNING! Check that the petrol pipe (4) is

intact and secured correctly before pouring in

new fuel.

B) Cleaning the tank

11 Remove the conveyor (1) secured by three nuts

(2).

12 Remove the ring (5) from the tank side, discon-

nect the petrol pipe (4) and drain all the fuel from

the tank into a suitable container.

13 Remove the tank cap (6) and blow compressed

air through the tube (7) to remove deposits from

the internal mesh filter.

14 Keep the tube hole (7) closed, pour in approx.

100 cl of clean petrol and shake well to clean

inside the tank.

15 Empty the tank and dispose of the petrol used

for cleaning in accordance with the laws in

force.

16 Remount the conveyor.

WARNING! Check that the petrol pipe (4) is

intact and secured correctly before pouring in

new fuel.

C) Checking and cleaning the breather pipe

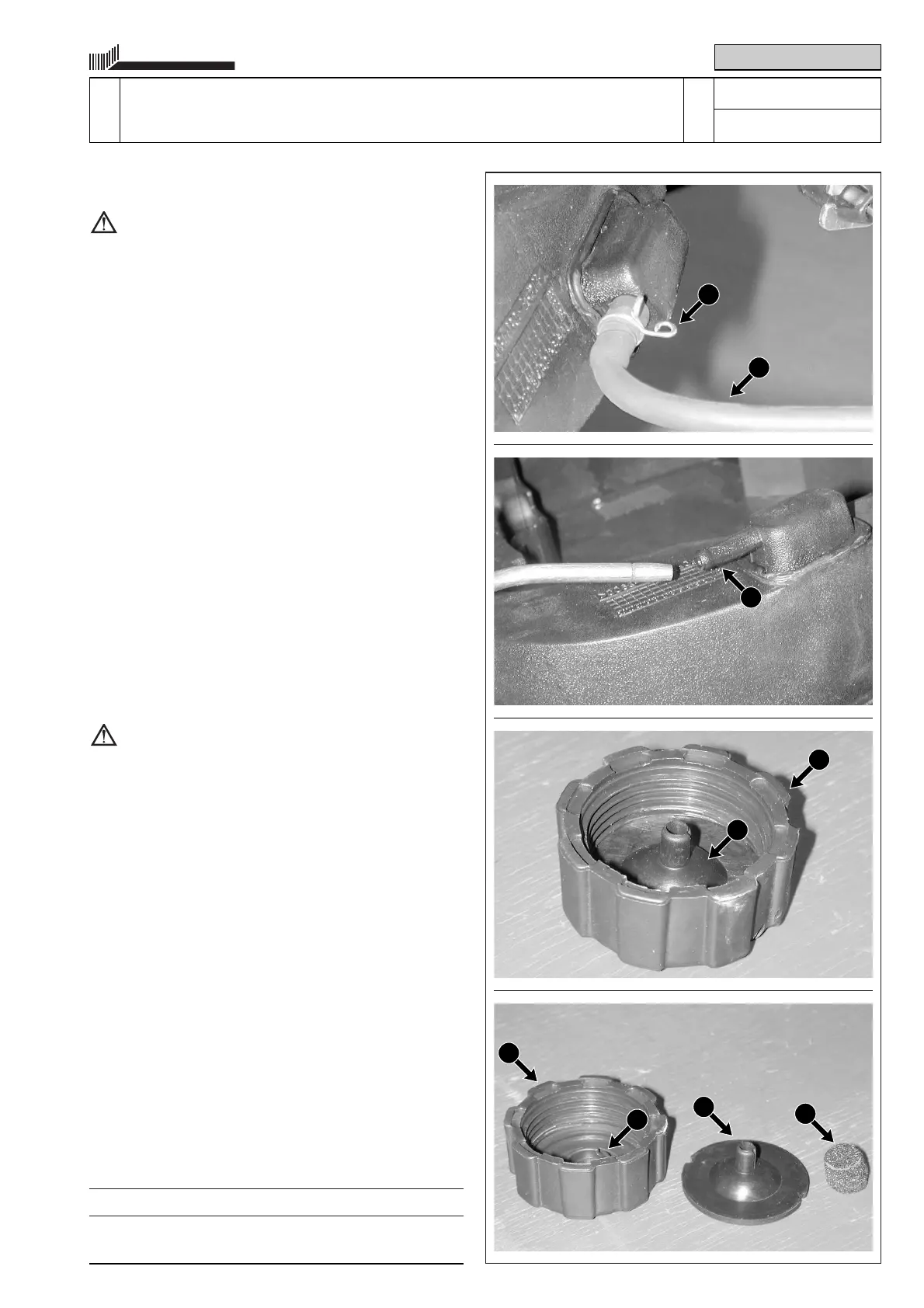

21 Remove the cap (6) and pull out the gasket (8)

and the sponge (9).

22 Check that:

– the gasket (8) is intact and without cracks or

fissures;

– the air passages (10) inside the cap are not

clogged;

– the sponge (9) is not crushed or broken.

NOTE

Always replace the entire cap if the gasket or

sponge is damaged.

Tightening torques

2 Conveyor nuts ...................................... 4-7 Nm

SV 150

6.1.0

TANK AND SUPPLY

2 / 2

WORKSHOP MANUAL

page

from

2004 to ••••

01/2005

10

8

6

5

4

6

8

9

7

Loading...

Loading...