5 6

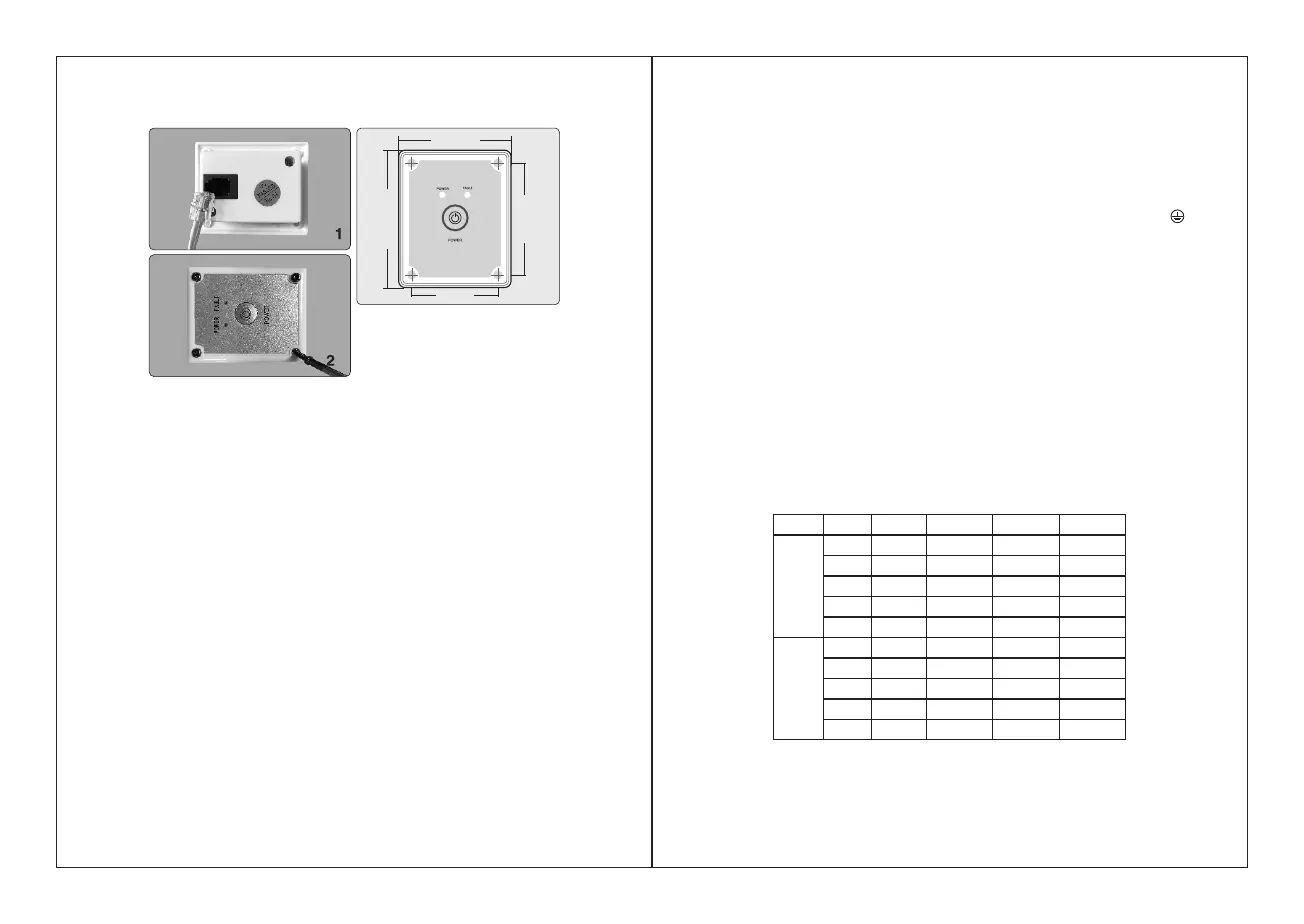

2). Assemble the remote control box

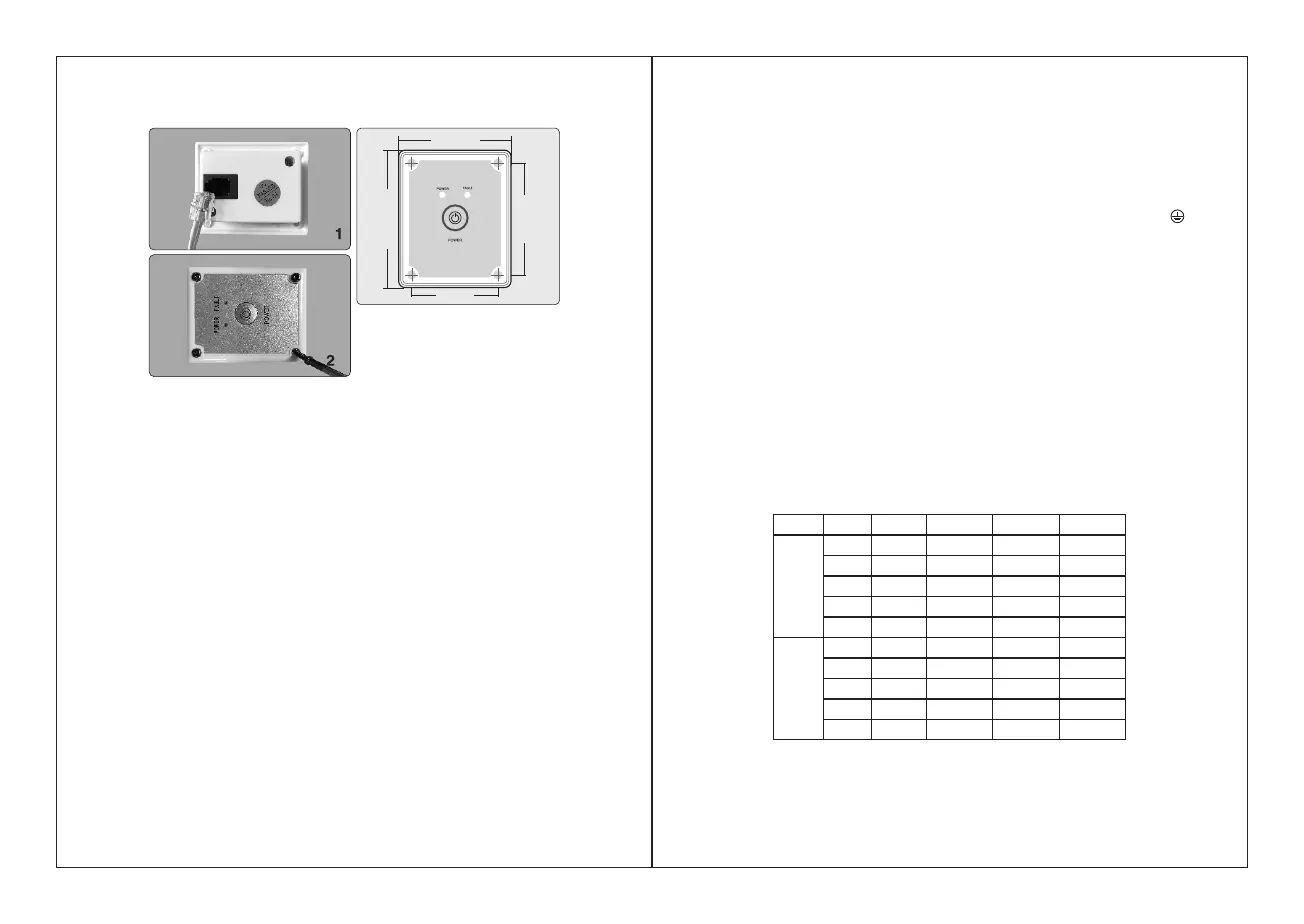

54 mm

66 mm

52 .5mm

41 mm

1) Fixed on the plane with an opening, four screws can be fixed directly on the four

mounting holes of the remote control box.

2) Connect the remote control cable between the box and the inverter.

5. BATTERY

1. The battery is designed to supply the inverter with DC input voltage and the rated

voltage should be in accordance with the rated input voltage of the inverter. Any

voltage exceeding the range of the input voltage of the inverter will cause the inverter

to go into overload and could possibly damage the inverter. The battery should

supply enough current for the load. The load is the amp or watt rating of the

equipment being powered by the inverter. A small capacity battery cannot provide

enough power for a large electrical equipment. In this case, the battery will cause the

inverter to go into under voltage protection because of the load put on the battery. A

simple way to calculate the load or amps required from your battery is to divide watts

of equipment by battery voltage. Due to the consumption of the inverter itself, the

actual current will be about 10%. For example, the voltage of lead acid battery is

12VDC, and load of the equipment is 1000W, therefore, the actual current needed

from the battery is about 1000W / 12V = 83.3 amps per hour. Add 10% for efficiency

loss and you get 83.3 * 110% = 91.6 amp per hour needed. If you don't know the

wattage of your equipment, you can figure the wattage by multiplying AC amps by AC

voltage. For example, a refrigerator is 8 AC amps * 120 Volts AC = 960 watts.

Remember, all equipment has a start-up requirement 3-5x its running wattage. In this

example, 960 watts * 3 = 2880 watts needed from the inverter so don't size your

inverter too small.

2. Battery operating time

The battery operation time depends on battery capacity and load. The formula for

operating time is: battery capacity divided by the value of the load divided by battery

voltage times 110%. For example, using the numbers from above, the batter

specification is 12V, 200Ah capacity and the load is 1000W. Take battery capacity

200Ah / 91.6 amps = 2.18 hours of run time if you fully deplete the battery. This is

NOT recommended. Deep cycle batteries last longer when they are only depleted to

50% of capacity.

6. CONNECTION

1) Grounding

The power inverter has a terminal on the rear panel marked " Grounding "or " ".

This is used to connect the chassis of the power inverter to ground. The ground

terminal has already been connected to the ground wire of the AC output receptacle

through the inverter.

The ground terminal suggested be connected to the ground wire, which will vary

depending on where the power inverter is installed. In a vehicle, connect the ground

terminal to the chassis of the vehicle. In a boat, connect it to the boat’s ground

system. In a fixed location, connect the ground terminal to earth.

2) Battery terminals

Before you connect the battery cables, make sure the power switch is in the off

position. Connect Red (+) battery cable to Red (+) inverter terminal. Connect Black (-

) battery cable to Black (-) inverter terminal. Connect Red (+) battery cable to Red (+)

battery terminal. Connect Black (-) battery cable to Black (-) battery terminal.

Alligator clamp cables may be used but only to connect to the battery. Do not use

clamps on inverter terminals. Alligator clamps are not a permanent solution. You may

see a spark during connection. Do not reverse the polarity. This may damage the

inverter and void warranty.

Cross-sectional cable must be thick enough to avoid too much voltage drop . Refer to

below table to choose cables.

Rate d vo lt age

of inv er te r

Curr en t ma x.

load p ow er

Max. c ur re nt

of wir e

Spec if ic ation of

wire l en gth≤1m

Spec if ic ation of

wire l en gth≤1m

Spec if ic ation of

wire l en gth≤N m

1200W

1500W

2000W

2500W

3000W

1200W

1500W

2000W

2500W

3000W

12V

6AWG

(13.3mm )

2

4AWG

(21.15mm )

2

3AWG

(26.67mm )

2

2AWG

(33.62mm )

2

1AWG

(42.41mm )

2

N×6AWG

(N×13.3mm

2

)

N×4AWG

(N×21.15mm

2

)

N×3AWG

(N×26.67mm

2

)

N×2AWG

(N×33.62mm

2

)

N×1AWG

(N×42.41mm

2

)

3AWG

(26.67mm

2

)

1AWG

(42.41mm

2

)

0AWG

(53.49mm

2

)

00AWG

(67.43mm

2

)

000AWG

2

(85.01mm )

24V

100A

150A

200A

250A

300A

50A

75A

100A

125A

150A

9AWG

(6.63mm )

2

7AWG

(10.55mm )

2

6AWG

(13.3mm )

2

5AWG

(16.77mm )

2

4AWG

(21.15mm )

2

N×9AWG

(N×6.63mm

2

)

N×7AWG

(N×10.55mm

2

)

N×6AWG

(N×13.3mm

2

)

N×5AWG

(N×16.77mm

2

)

N×4AWG

(N×21.15mm

2

)

6AWG

(13.3mm

2

)

4AWG

(21.15mm

2

)

3AWG

(26.67mm

2

)

2AWG

(33.62mm

2

)

1AWG

(42.41mm

2

)

Loading...

Loading...