MAR 2018 GFV-305 (Formerly H-3) Page 2 of 11

MODEL RCW DRY SYSTEM

The dry system trim is one optional trim arrangement for

the Globe Model RCW valve. This arrangement is typically

utilized when the system is subject to areas exposed to

freezing or close to freezing temperatures. With this con-

guration, the detection system consists of automatic sprin-

klers spaced throughout the protection area. System air

pressure is used to ensure the integrity of the system piping

and used as the activation method for the valve.

Water pressure is maintained in the valve pressure chamber

up to the dry pilot actuator through a restricted connection

from the main water supply which is taken upstream of the

system main control valve (The pressure chamber supply

valve must remain in the open position at all times when the

system is in service). The dry pilot actuator is normally held

in the closed position by the system air pressure supplied

through the automatic air or nitrogen maintenance device.

When an automatic sprinkler operates, the air ow rate

through the open sprinkler is at a ow rate greater than that

which can be supplied through the automatic air or nitrogen

maintenance device. This causes a pressure drop in the

system and the upper chamber of the dry pilot actuator. An

optional accelerator can increase the rate at which the air

decays on the dry pilot actuator, if a faster time to trip the

Model RCW valve is required.

Once the pressure in the upper chamber of the dry pilot

actuator drops sufciently, the upper chamber can no lon-

ger hold the diaphragm in the closed position. The dry pilot

actuator opens and allows water to ow from the pressure

chamber to the drain at a ow rate greater than that which

can be supplied through the restriction in the pressure

chamber supply line. The opening of the dry pilot actuator

results in a drop in pressure in the pressure chamber and

the Model RCW valve operates (trips) allowing water to ow

into the system piping. The automatic actuation of the fea-

ture of the valve can be bypassed by manually rotating the

handle on the "Manual Control/ Emergency Release" valve

located on the Model RCW trim to activate the Model RCW

valve.

Note:

See recommended system air/nitrogen pressure and expected trip range below

for the Model GDPA. More detailed information can be found about the Dry

Pilot Actuator in Technical Data Sheet GFV550.

GDPA VS GDPA-LP

When choosing the dry pilot actuator for your system

there are many factors which inuence the uid deliv-

ery time. These factors range from system geometry,

riser location, sprinkler orice size, supply pressure,

pump ramping time and more. In certain systems,

higher system air pressure can be advantageous over

lower system air pressure and the opposite can also

be true. Some things to consider when choosing the

GDPA vs the GDPA-LP are discussed below.

The initial air pressure in a system may vary. For ex-

ample in one system the initial air pressure may be set

for 15 psi (1 Bar) and 45 psi (3.1 Bar) for the other. The

system air pressure will decay at a faster rate with the

higher initial system pressure. For a xed pressure

drop (i.e. 5 psi drop) will be reached more quickly with

the higher initial air pressure than lower initial air pres-

sure.

Unfortunately uid delivery time is not just dependent

on tripping the control valve but also dependent on

the uid moving through the system. As the water lls

the system piping it can create a high pressure pocket

of air at the inspectors test connection. This higher

air pressure can slow the progress of the water pro-

gressing towards the inspectors test connection. This

phenomenon typically happens with smaller K-factor

sprinklers. This scenario may lend itself to choosing

to utilize lower system air pressure and the GDPA-LP

actuator.

In other circumstances, systems are center fed, mean-

ing roughly half of the volume of piping is on one side

of the riser and half on the other. In these scenarios,

higher system air pressure can be benecial to system

delivery time as the higher air pressure will actually im-

pede or stop the propagation of water in the direction

opposite the inspectors test connection (ITC) and force

the majority of the available water ow towards the ITC.

It would be impossible to run through every scenario

possible but there are a few generalities which can

be used as guidance. Generally end fed systems will

achieve faster uid delivery times with lower air pres-

sure. Generally center fed systems with moderate to

better than moderate water supplies will have faster

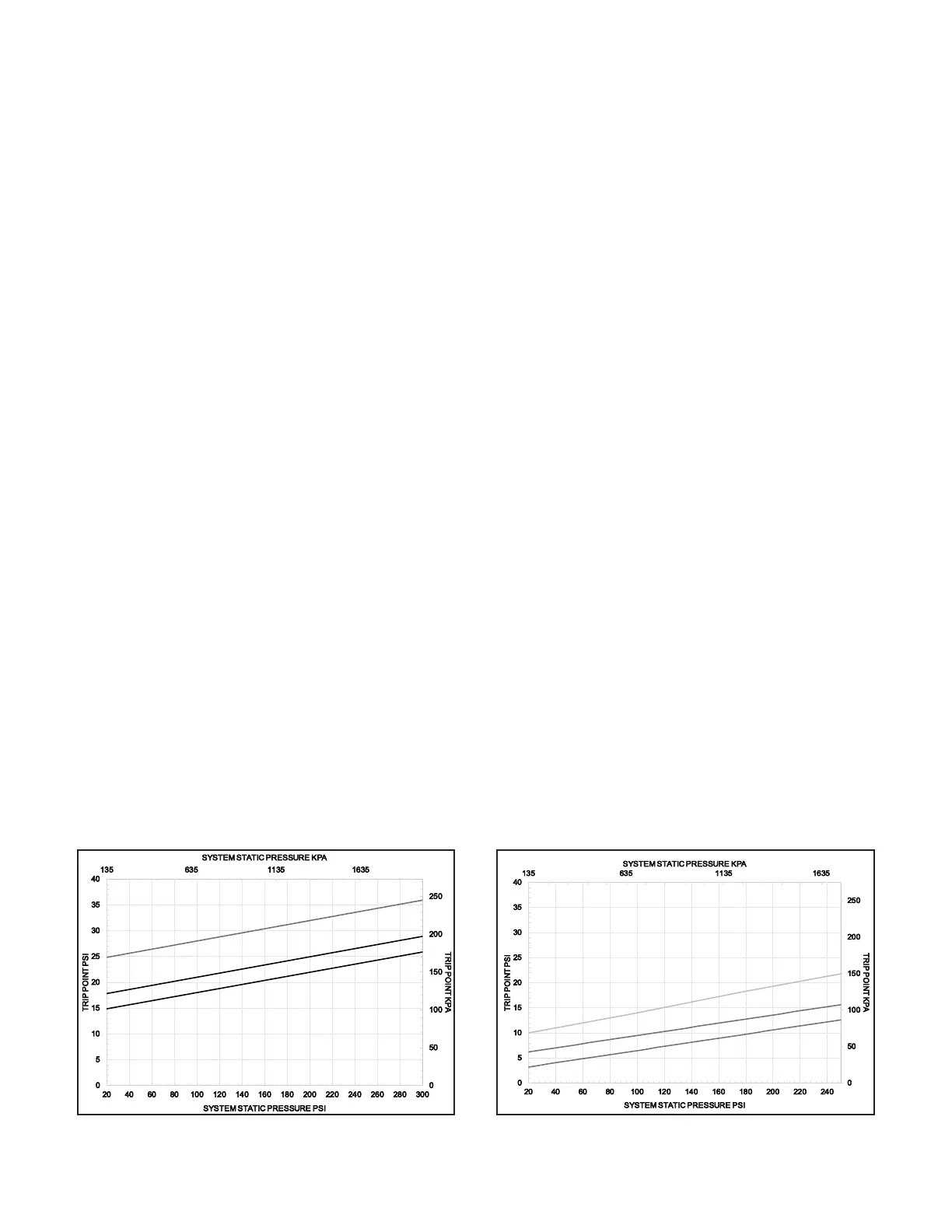

FIGURE 1:MODEL GDPA DRY PILOT

TRIP RANGE

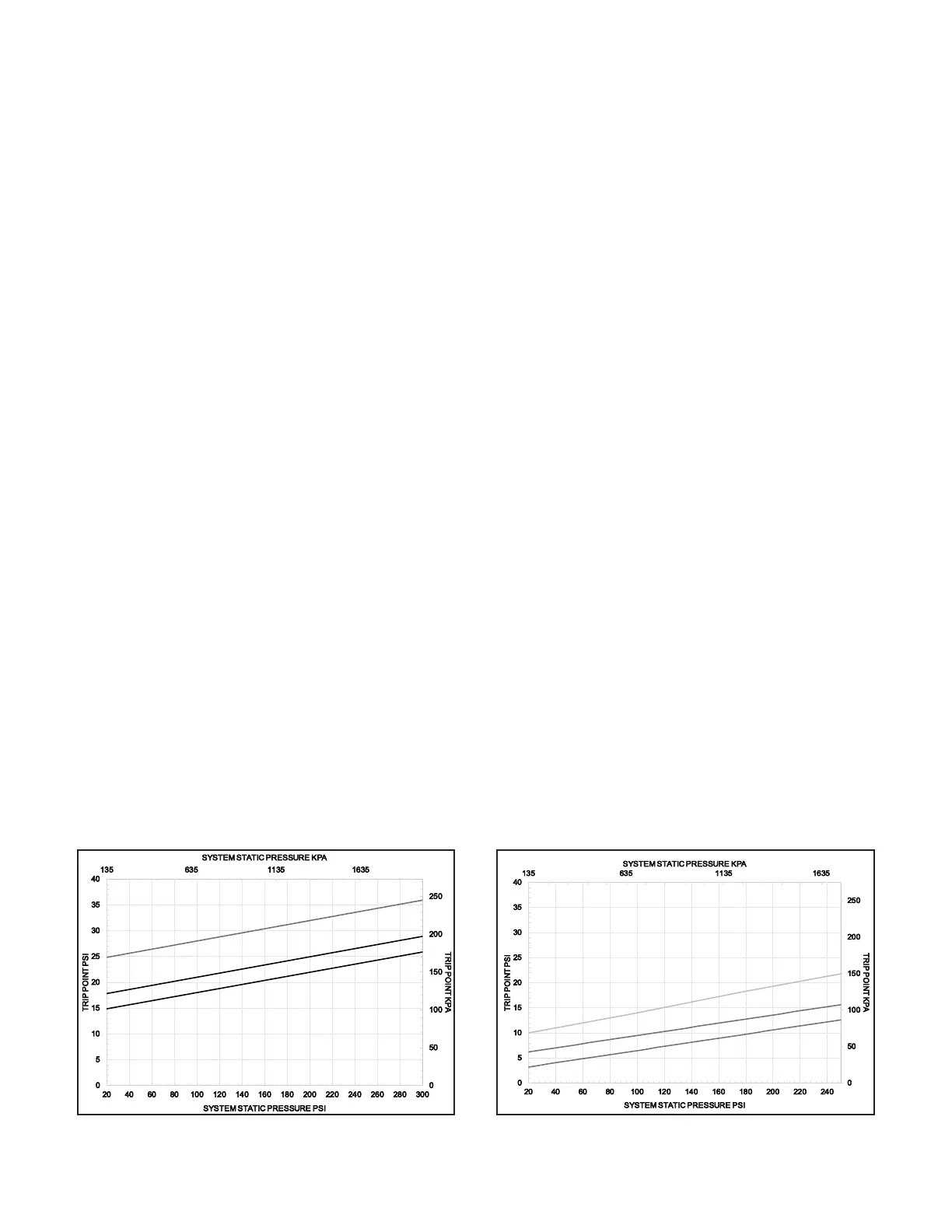

FIGURE 2:MODEL GDPA-LP DRY

PILOT TRIP RANGE

GDPA-LP Trip Range

Recommended Air/Nitrogen Pressure

Recommended Air/Nitrogen Pressure

GDPA Trip Range

Loading...

Loading...