0020313973_01 Compact Installation and maintenance instructions 43

Appendix

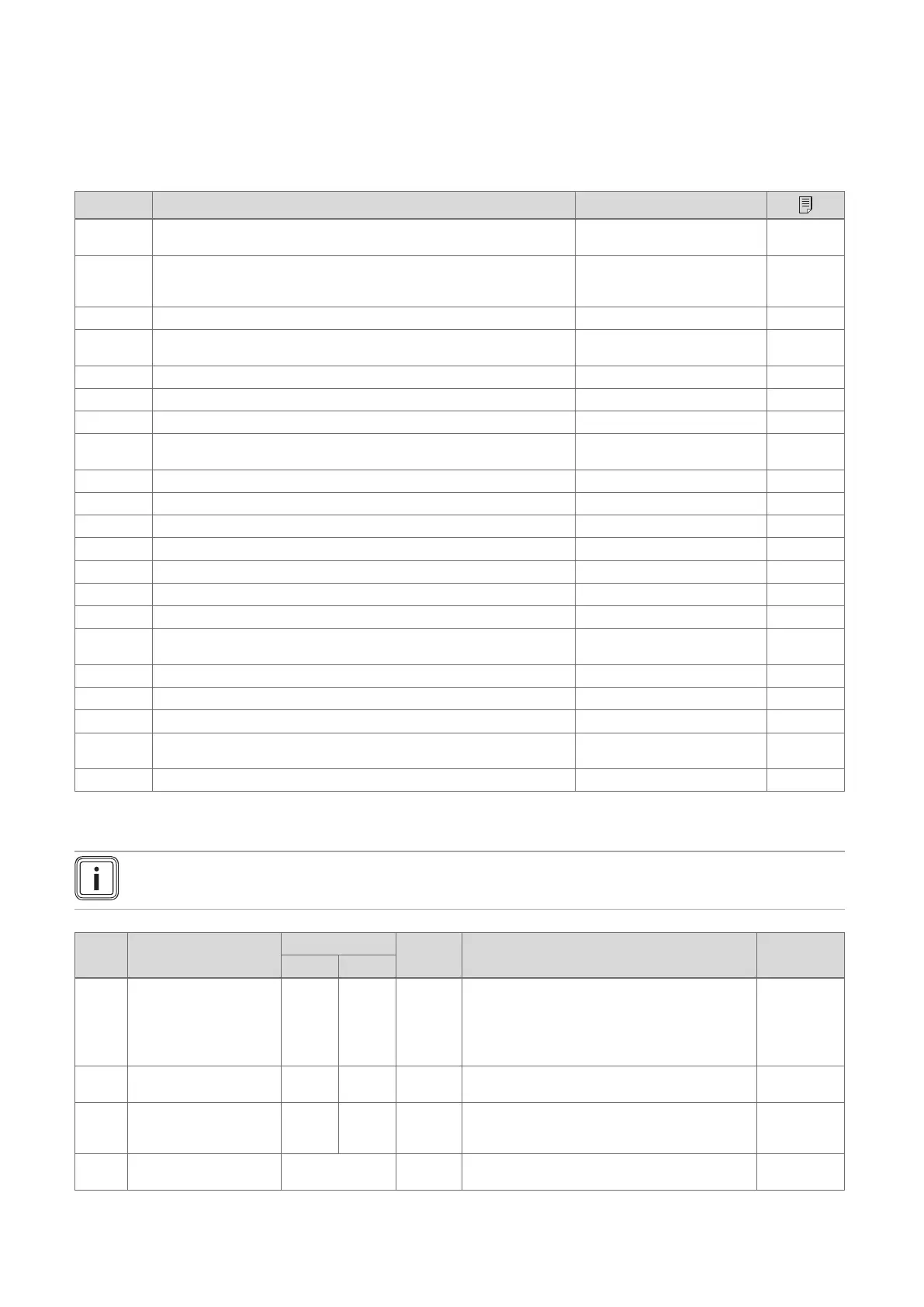

A Inspection and maintenance work

The table below lists the manufacturer requirements with respect to minimum inspection and maintenance intervals. If na-

tional regulations and directives require shorter inspection and maintenance intervals, you should observe these instead of

the intervals listed. Each time inspection and maintenance work is carried out, carry out the required preparatory and com-

pletion work.

# Maintenance work Interval

1 Record all of the analysis results in the Benchmark Checklist in these

instructions

Annually

2 Check the tightness of the air/flue pipe, make sure that it is not damaged

and has been attached correctly, and check that it has been set up cor-

rectly

Annually

3 Removing dirt from the product and the vacuum chamber Annually

4 Visually checking the condition of the heat cell, checking for corrosion,

rust or damage

Annually

5 Checking the gas connection pressure at maximum heat input Annually

6 Checking the CO₂ content Annually

31

7 Recording the CO

2

content (the air ratio) Annually

8 Check that the connections/electrical plug connections have been con-

nected correctly/function correctly (product must be voltage-free)

Annually

9 Check that the gas stopcock and service valves function correctly Annually

10 Cleaning the condensate siphon Annually

39

11 Cleaning the heating filter Annually

39

12 Checking the pre-charge pressure of the expansion vessel at regular intervals

39

13 Removing the compact thermal module at regular intervals

36

14 Cleaning the heat exchanger at regular intervals

37

15 Checking the burner and burner insulating mat for damage at regular intervals

37

16 Checking the insulating mats in the combustion area and replacing dam-

aged insulating mats

at regular intervals

17 Installing the compact thermal module at regular intervals

38

18 Checking the ignition electrode at regular intervals

38

19 Checking the filling pressure of the heating installation Annually

20 Run a function test for the product/heating installation and the domestic

hot water generation. If required, carry out purging.

Annually

21 Completing inspection and maintenance work Annually

40

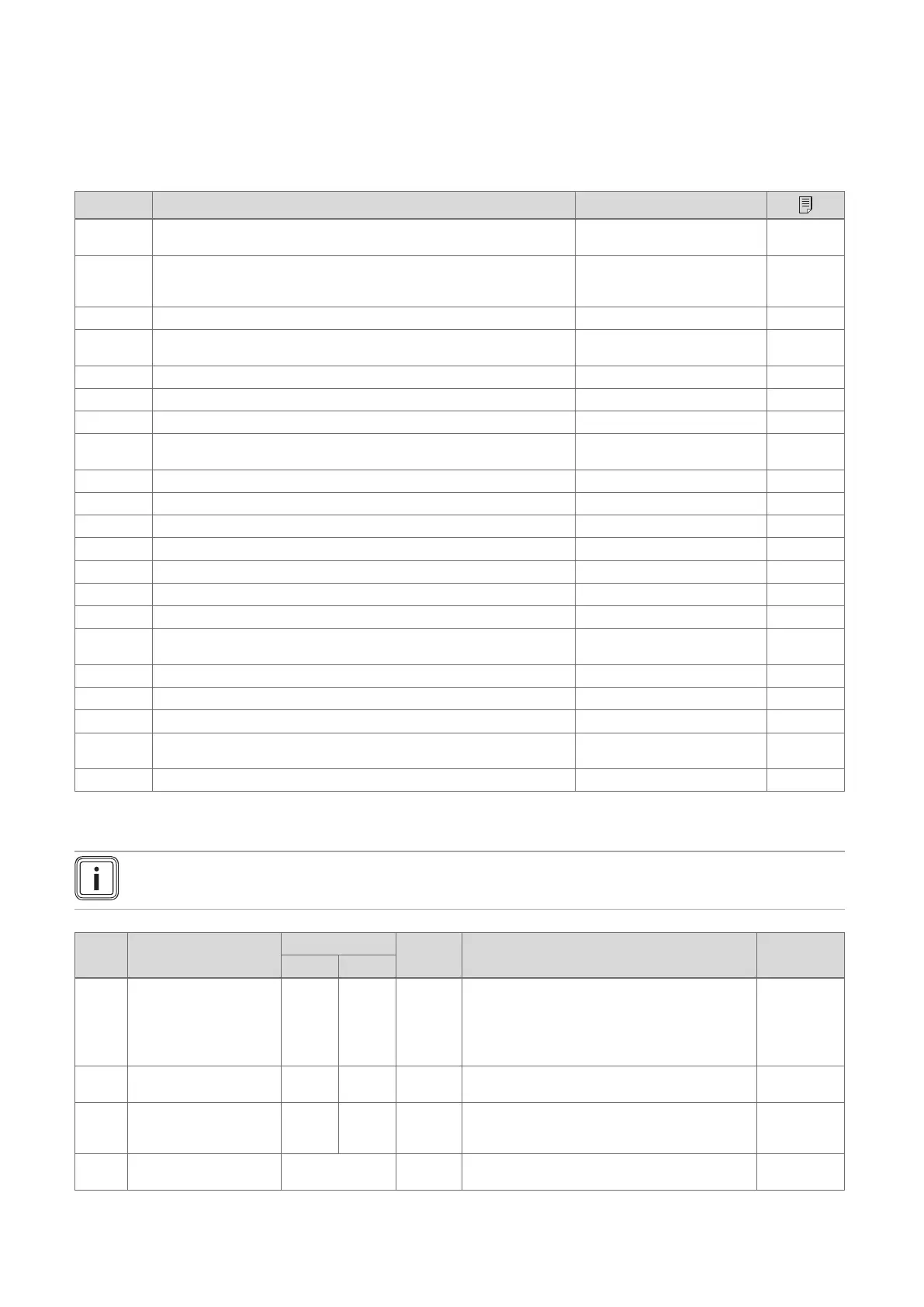

B Diagnostics codes

Note

Since the code table is used for various products, some codes may not be visible for the product in question.

Code Parameter

Values

Unit Increment, select, explanation

Factory

setting

Min. Max.

d.00 Maximum heat output is

fixed or adjusts automat-

ically

– – kW The maximum heat output varies depending on

the product.

→ Section "Technical data"

Au = Automatic: Product automatically adjusts the

maximum output to the current system demand

Au =

Automatic

d.01 Pump overrun time in

heating mode

1 60 min Increment = 1 5

d.02 Maximum burner anti-

cycling time in heating

mode

2 60 min Increment = 1 20

d.05 Determined target heat-

ing flow temperature

Current value ℃ – –

Loading...

Loading...