42

AUTOMATIC

BYPASS VALVE

BYPASS SCREW

12.5 Gas Rate

The gas valve is factory set for natural gas G20 and should need

no adjustment.

Should any doubt exist about the gas rate, check it using the

gas meter test dial and stop watch at least 10 minutes after the

burner has lit, making sure that all other gas burning appliances

and pilot lights are off.

The boilers are fully modulating for central heating, and it is

therefore not necessary to range rate the boiler.

For approximate gas rates, refer to section 1 Specification Table.

The gas valve is factory set for natural gas (G20) and should

need no adjustment. It should be checked that the supply

pressure is 20mbar when the boiler is firing at full rate. This can

be achieved by turning on several hot water taps and checking

the inlet pressure at the pressure test point on the gas service

cock, see diagram 12.1. Turn taps off and disconnect pressure

gauge.

In the unlikely event that the gas valve needs adjusting, refer to

section 13 Servicing - Combustion Check. Re-setting of the gas

valve requires a combustion analyser and any adjustment should

only be carried out by a competent person.

NOTE: The burner pressure cannot be measured at the gas valve

as it is altered by the suction of the fan and modulated according

to demand.

Testing Flue Gases: If any doubt exists that the flue products

are not exhausting correctly, investigate by use of a flue gas

analyser.

12.6 Range Rating

The boilers are fully modulating for central heating, and it is

therefore not necessary to range rate the boiler. However, if

desired, it is possible to range rate the boiler between 9 and

24kW in 1kW increments as follows:

a) Press and hold the ‘MODE’ button for 5 seconds.

The display will change to flashing ‘0’.

b) Use the ‘+’ or ‘-’ button to scroll to 96.

c) Press ‘MODE’ to confirm.

d) The display now shows a flashing ‘d.

0’. The part

load setting is displayed above in kW

e) Press ‘MODE’ to change, use the ‘+’ or ‘-’

button to change this value to the desired setting.

h) Press ‘MODE’ to confirm, the new setting has been

saved.

i) Press and hold ‘MODE’ to exit.

NOTE: For approximate gas rates at part load, refer to table

below.

12 Commissioning

13234

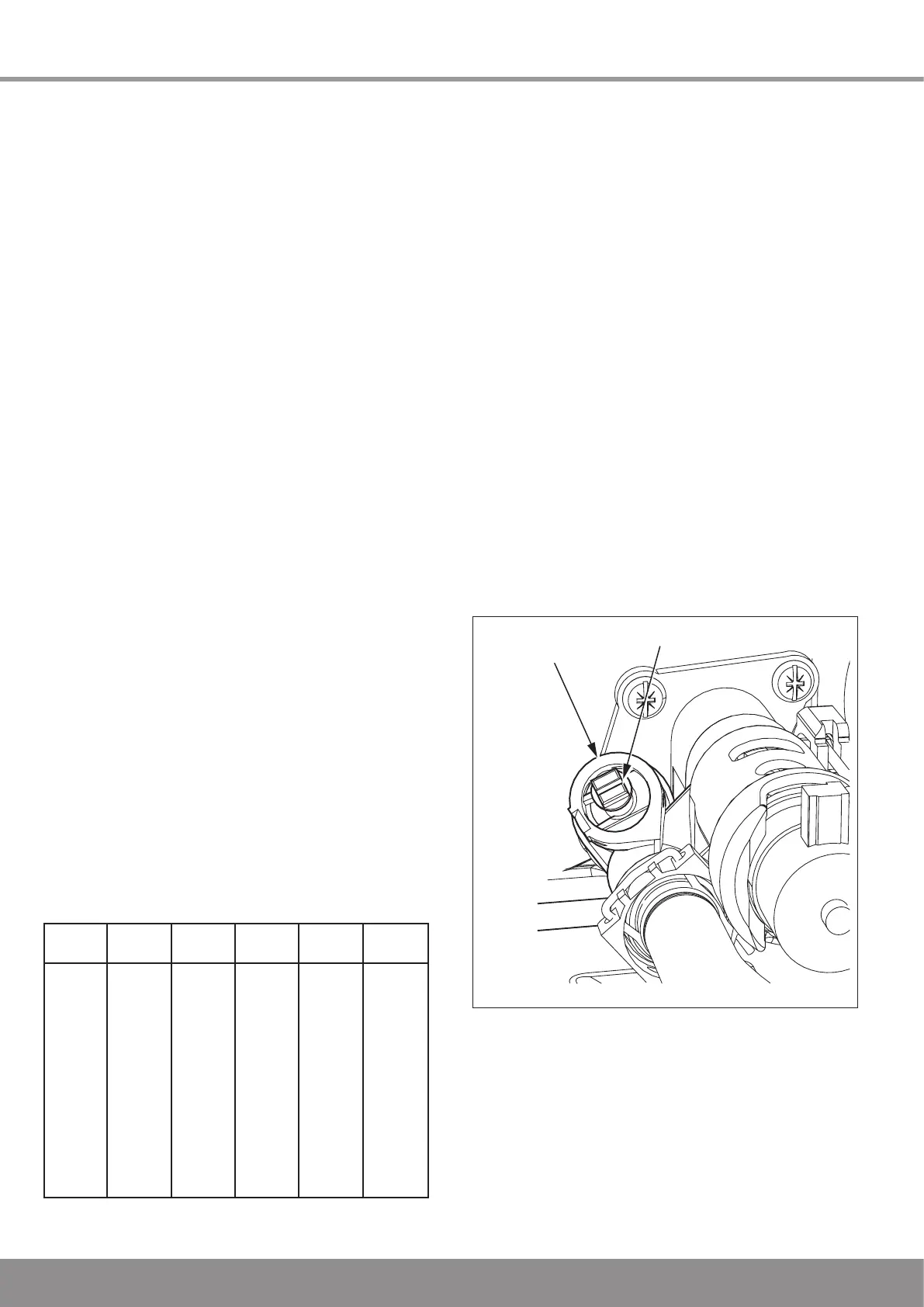

Diagram 12.5

12.7 Water Systems

Check that all external controls are calling for heat, the boiler

will fire automatically. Fully open all radiator valves and the

flow control valve, if fitted, see diagram 4.1.

Balance the radiators as required and if fitted adjust the valve

to give the required system differential. Turn off all radiators

that can be shut off by the user and check to see if less than

the maximum differential allowed of 20

o

C can be achieved

across flow and return.

The pump has two speeds and can be adjusted depending

on the requirements of the central heating system, see

diagram 4.2.

The boiler has an inbuilt automatic adjustable bypass valve.

The pressure can be adjusted between approx 1.5 and

3.5mH2O but is factory pre-set to approx 2.5mH2O. The

pressure changes by approx 0.1mH2O for each full turn

of the bypass screw, see diagram 12.5. Turning clockwise

increases the pressure and turning anti-clockwise decreases

the pressure.

Allow the system to reach maximum temperature then switch

off the boiler by isolating from the electrical supply.

Lock or remove the handle from the control valve, if fitted.

Adjust the boiler temperature controls and any system

controls to their required settings.

We recommend that the domestic hot water should be run for

a short period until clear.

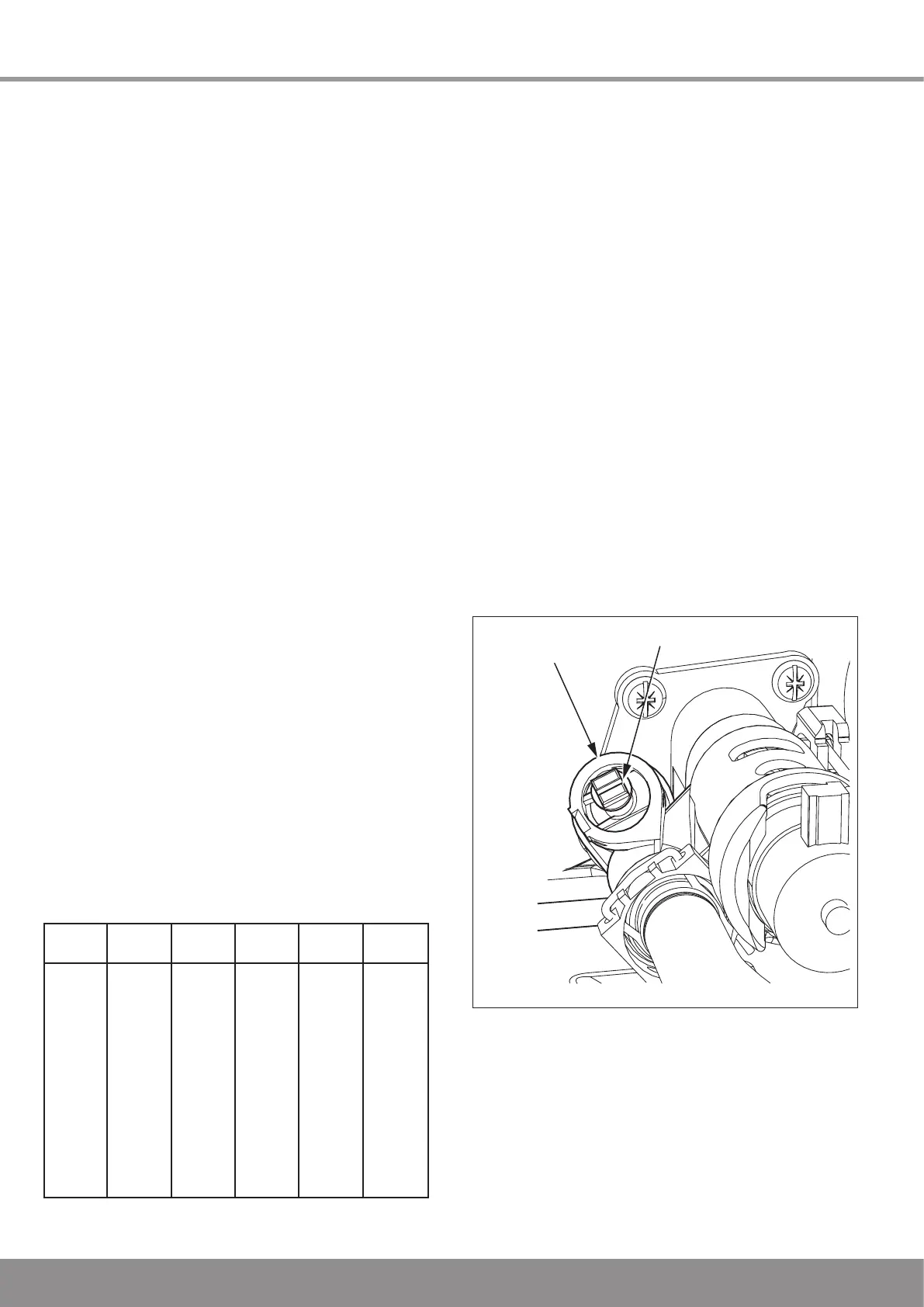

kW m3/hr ft3/hr kW m3/hr ft3/hr

24 2.5 88.6 16 1.7 58.9

23 2.4 84.7 15 1.6 55.4

22 2.3 81.2 14 1.5 51.5

21 2.2 77.3 13 1.4 48.0

20 2.1 73.8 12 1.3 44.1

19 1.1 69.9 11 1.2 40.6

18 1.9 66.4 10 1.0 36.7

17 1.8 62.9 9 0.9 33.2

Loading...

Loading...