16 308899

Maintenance

Pressure Relief Procedure

INJECTION HAZARD

To reduce the risk of serious injury,

including fluid injection, splashing in the

eyes or on the skin, or injury from mov-

ing parts, always follow this procedure whenever

you shut off the pump, and before inspecting,

removing, cleaning or repairing any part of the

pump or system.

WARNING

1. Close the supply pump’s bleed-type master air

valve (required in pneumatic systems).

2. Open the dispensing valve until pressure is fully

relieved.

3. Open the fluid drain valve at the pump fluid outlet.

Leave the drain valve open until you are ready to

use the system again.

If you suspect that the dispensing valve, extension, or

grease fitting coupler is clogged, or that pressure has

not been fully relieved after you have followed the

steps above, very slowly loosen the coupler or hose

end coupling to relieve the pressure gradually, then

loosen it completely. Then clear the clog.

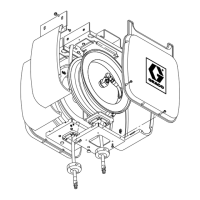

Replacing the Service Hose

1. Relieve the pressure.

INJECTION HAZARD

To reduce the risk of serious injury

whenever you are instructed to relieve

pressure, always follow the Pressure

Relief Procedure above.

WARNING

2. Fully extend the hose, and latch the reel.

3. Attach a C-clamp (G) to the reel flange to help

prevent the reel from unintentionally becoming

unlatched and spinning freely. See Fig. 12.

Fig. 12

36

37

G

03724B

Never allow the reel to spin freely. Doing so

causes the hose to spin out of control, which could

cause serious injury if you are hit by the hose.

WARNING

Loading...

Loading...