20 308899

Service

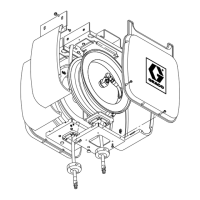

Fig. 17

18a

36

C

31

A

6

03727A

9. To remove the roller support assembly (A),

remove the three screws (18a), and lift the arm off

the reel. See Fig. 17.

10. Remove the nut (6), and remove the hose drum

(C) from the base (36). Lay the drum on a work

bench with the ratchet (31) side down.

11. For Low- and Medium-Pressure Hose Reels,

remove the retaining ring (12), swivel (34),

retaining ring (11), and spacer (21). See Fig. 15

on page 18.

For High-Pressure Hose Reels, remove the swivel

assembly (34), retaining ring (11), and spacer (21).

See Fig. 14 on page 18.

12. Before you continue with this procedure, read

the Warning below.

WARNING

Use extreme caution when handling the spring.

The spring (25), which is located behind the flange

(26), is always under great tension and could be

propelled from the lower flange with enough force

to cause serious injury. See Fig. 18.

To reduce the risk of serious injury when doing any

repair work that exposes you to the spring, be sure

to carefully follow the instructions below. Be sure

you understand this procedure before continuing

with the repair work.

13. Remove the screws (13), nuts (9), and retaining

ring (28) from the reel flanges (26 and 40). See

Fig. 18 on page 21 and the Parts Drawing on

page 22.

14. Lay the reel flat. With extreme caution, lift up on

the flange (26) to expose the spring (25).

15. Carefully inspect the spring.

If either end of the spring (25) is worn or damaged

and does not hook properly on the reel hub (24) or

the pin (C), the spring needs to be replaced. See

Fig. 18. If the pin itself is broken, the lower reel

flange (40) must be replaced.

16. To remove the spring, use locking pliers (A) placed

near the end of the spring, as shown, to compress

several rows of the spring (25) together, and lift out

the spring. See Fig. 18.

17. Before disposing of the spring, carefully attach a

minimum of two hose clamps (B) around the

keeper (D) and spring (25) bands as shown in

Fig. 19.

18. When greasing and installing the new spring, coat

the new spring and the flange (40) with a multi-

purpose, lithium-based grease before installing the

spring. Use a locking pliers (A) to compress

several rows of the spring (25) together. See

Fig. 18.

Loading...

Loading...