Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2006, Graco Inc. is registered to I.S. EN ISO 9001

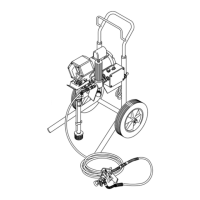

- For portable spray application of architectural paints and coatings -

Models: 253958, 262019, 254968, 254969, 254998, 253961

Maximum Working Pressure: 3300 psi (227 bar, 22.7 MPa)

IMPORTANT SAFETY INSTRUCTIONS!

Read all warnings and instructions. Save these instructions. Contact Graco Customer Service

or your local Graco distributor to obtain a manual in your language.

311732

309639

309250

311761

Related Manuals

ti5635b

ti11626a

Stand

Hi-Boy

311737B

Repair

390

™

Electric Airless

Sprayer