Graf UK Ltd

. OPERATION OF THE CONTROL SYSTEM

OPERATION OF THE CONTROL SYSTEM

4

4.2.5 Old Faults

The controll system stores all past fault messages and the operation of the control system via the “manual mode”

function. Past fault messages with date and time can be read under the menu item “Old faults”. The individual messages

can be accessed using the arrow keys. You can exit the menu item by pressing .

Faults are indicated as encoding, in order of their appearance, starting with number 0 (latest signal).

The faults number 2 (net is back) and number 5 (manual operation) are no faults. They will be registered for a better

temporal localization of possibly occurring faults or rather monitoring of manual activities on the control system.

4.2.6 Display Settings

This menu item allows the current control system settings to be seen. It is not possible to change these settings. This

menu item is used to analyse the settings without making changes. The individual settings can be called up using the

arrow keys . You can exit the menu item by pressing .

4.2.7 Service Menu

Operating parameters can be changed in the service menu. Access is protected with a code. This second

maintenance level is reserved exclusively for qualified specialist personnel only!

Any access to the control system settings by unauthorised persons will cause the warranty to expire!

4. Operation of the Control System

25 / 57

4.1.1 Display of Operating Status

The operating status is indicated by the LEDs (green = operational / red = fault) and as text on the screen.

In normal operating mode (aeration mode), the display appears as follows:

In automatic mode, the liquid crystal display shows the current work phase and the remaining time left in

this phase.

If a fault occurs, the red LED is turned on. A message indicating which component is faulty appears in the

liquid crystal display (e.g. Fault Compressor 0.0A).

4.1.2 The following work phases are displayed

Display

Process performed

Denitrification

Y3 valve (plug X1.1) is actuated intermittently; the activated sludge is briefly

mixed with the wastewater. This is followed by long pauses (response times).

Ventilation Y3 valve (plug X1.1) is actuated; the system is aerated in intervals over a long

period of time.

Sedimentation phase No valves are actuated, the activated sludge settles in the system.

Activity phase Y4 valve (plug X1.2) is actuated; the clear water is pumped into the drain.

Cycle pause/

holiday mode

Y3 valve (plug X1.1) is actuated; the system is aerated in intervals (considerably

less than in the aeration phase).

Rest: XXX:XXmin Display of remaining time.

Symbol Key assignment Function

Enter key Selection of operating mode, confirmation of entries

Scroll Display of operating modes and queries Programming of

the system by entering figures

Acknowledgement

Acknowledgement of entries without saving

Acknowledgement of fault messages

Aeration

Rest: 120:10min

4. Operation of the Control System

24 / 57

4. Operation of the Control System

The operation of the system is carried out via a microprocessor in the control unit. The microprocessor

allows for the set-up of operating parameters, the display of operating conditions and the query of system

parameters as well as the programming of working times through a specialist company.

Adjustments are made by scrolling through numerical values using the two arrow keys . The set-

tings are then confirmed by pressing the button.

The individual dialogues can be terminated ahead of time by pressing or will be terminated automati-

cally after 2 minutes.

The control system is broken down into the following display pages:

4. Basic level: Status of the cycle sequence with the elapsing remaining time, as well as the display of

error messages.

5. Operator level: The operator can access the operator level by pressing the button and enter oper-

ator-specific settings.

6. Service level: A password-protected service level can be accessed from the operator level using an

additional code. This level is reserved for trained personnel. Here adjustments or changes can be

made and diagnostic data is retrieved.

Figure 2: view of the operating unit

4.1 Control Programme

The control system switches the outputs for air compressors and stepper motors on a timer.

The timing is determined by the set sequence tables. A complete cleaning cycle is started for each start

time in accordance with the selected sequence table.

By setting up holiday times in the operator level, the complete sequence of cleaning cycles can be sup-

pressed for the set period of time. Only one holiday cycle with greatly reduced activity takes place at this

time. During this time, no treated wastewater will be removed, as there should be no supply.

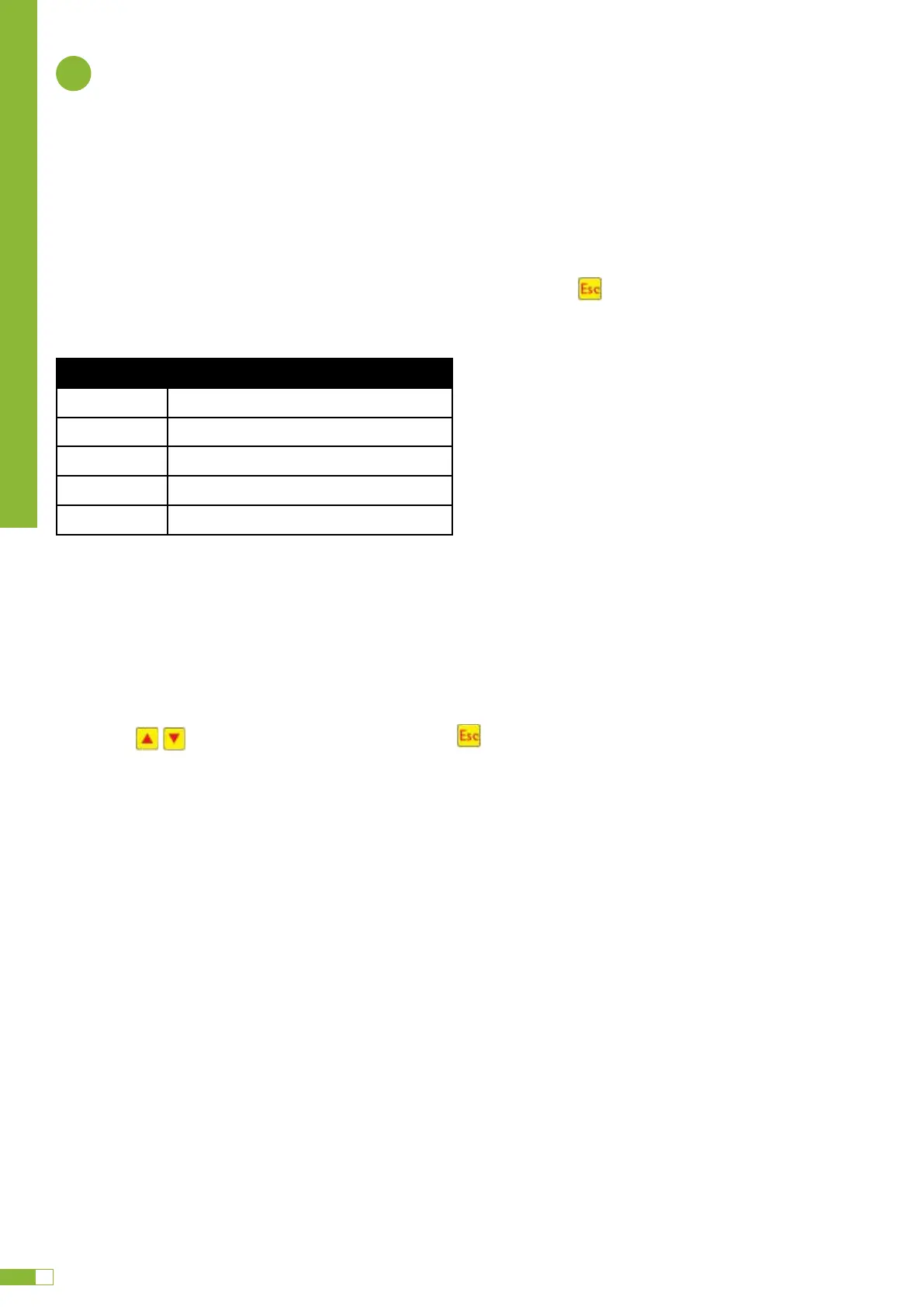

Coding Meaning

1 Power failure (system is currentless)

2 Net is back (system regains power)

3 Compressor has over-current

4 Compressor current supply too low

5 Manual operation

4. Operation of the Control System

25 / 57

4.1.1 Display of Operating Status

The operating status is indicated by the LEDs (green = operational / red = fault) and as text on the screen.

In normal operating mode (aeration mode), the display appears as follows:

In automatic mode, the liquid crystal display shows the current work phase and the remaining time left in

this phase.

If a fault occurs, the red LED is turned on. A message indicating which component is faulty appears in the

liquid crystal display (e.g. Fault Compressor 0.0A).

4.1.2 The following work phases are displayed

Display

Process performed

Denitrification

Y3 valve (plug X1.1) is actuated intermittently; the activated sludge is briefly

mixed with the wastewater. This is followed by long pauses (response times).

Ventilation Y3 valve (plug X1.1) is actuated; the system is aerated in intervals over a long

period of time.

Sedimentation phase No valves are actuated, the activated sludge settles in the system.

Activity phase Y4 valve (plug X1.2) is actuated; the clear water is pumped into the drain.

Cycle pause/

holiday mode

Y3 valve (plug X1.1) is actuated; the system is aerated in intervals (considerably

less than in the aeration phase).

Rest: XXX:XXmin Display of remaining time.

Symbol Key assignment Function

Enter key Selection of operating mode, confirmation of entries

Scroll Display of operating modes and queries Programming of

the system by entering figures

Acknowledgement

Acknowledgement of entries without saving

Acknowledgement of fault messages

Aeration

Rest: 120:10min

Loading...

Loading...