Graham Corporation

12

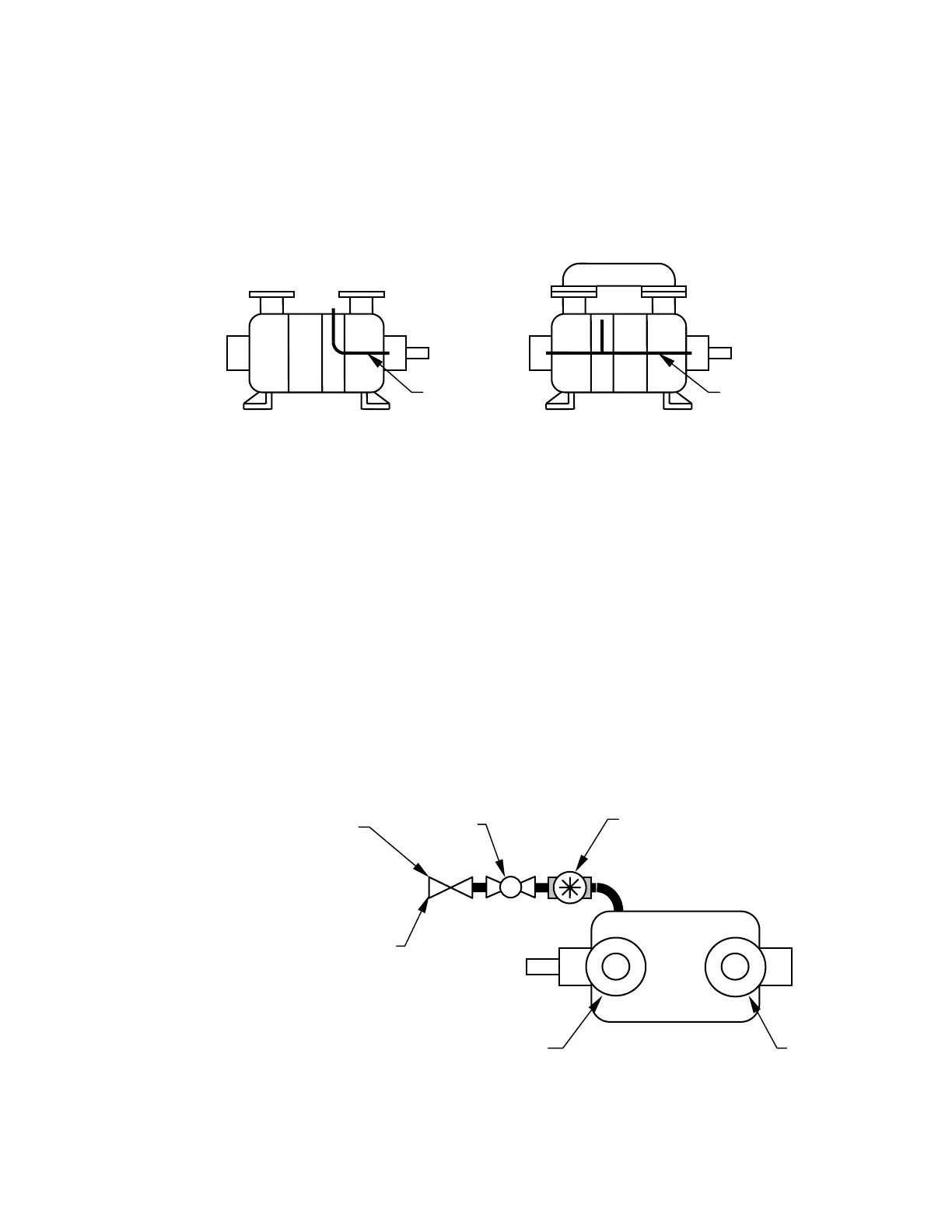

B) Series 2 Design

The Series 2 pumps use single mechanical seals for shaft sealing. A shaft seal tubing assembly

(or harness) is normally provided to flush/cool the seals with service liquid from the liquid ring.

(See Figure 3)

Size 90000 pumps have shaft seals that are flushed internally and no harness is required.

Standard Configuration

Figure 3

Note: If the service liquid contains contaminates, they will be forced to the outside of the liquid

ring by centrifugal force and then into the seal flush harness and mechanical seals. If there is a

concern that these contaminates may harm the mechanical seals, then each seal must be flushed

externally with 0.25 to 0.5 GPM (0.06 to 0.1 m

3

/hr) of clean, filtered liquid at 10 PSI (0.7 bar)

above the discharge pressure. To flush externally, remove the shaft seal harness and plug the

unused connection.

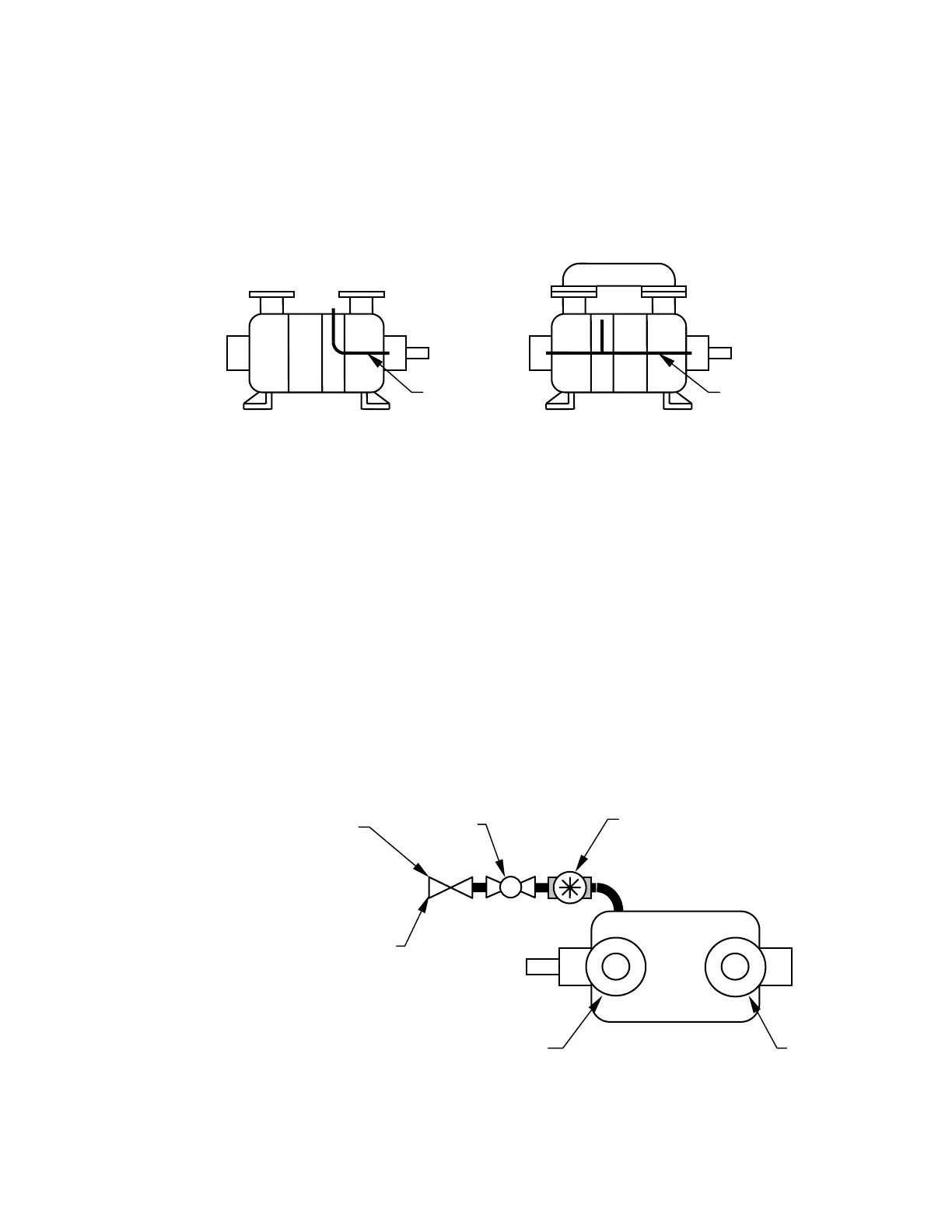

The size 30000 pump will require a seal coolant supply at the driven end only as the non-driven

end mechanical seal is cooled by the incoming service liquid. No drain piping is needed as both

seals drain internally. (See Figure 4)

Pump

Dischar

e

Figure 4 - Size 30000 Optional Configuration

Pump

Suction

Sight Flow

Indicator or

Rotameter

Shut-Off

Valve

Regulating

Valve

Harness

Size 40000 through 80000 Size 30000

Harness

Shaft Seal Coolant

Inlet at 10 PSI Above

the Dischar

e Pressure

Loading...

Loading...