Graham Corporation

16

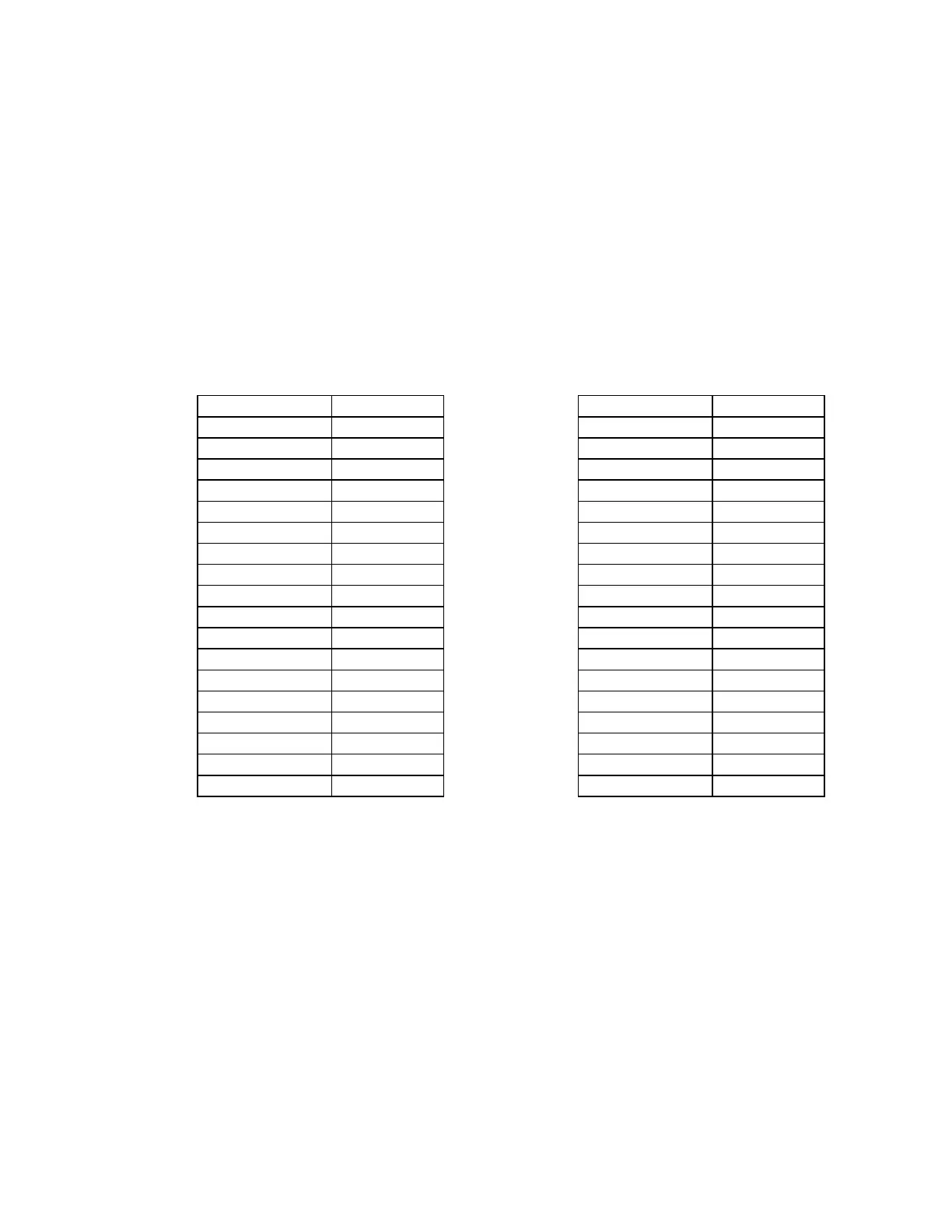

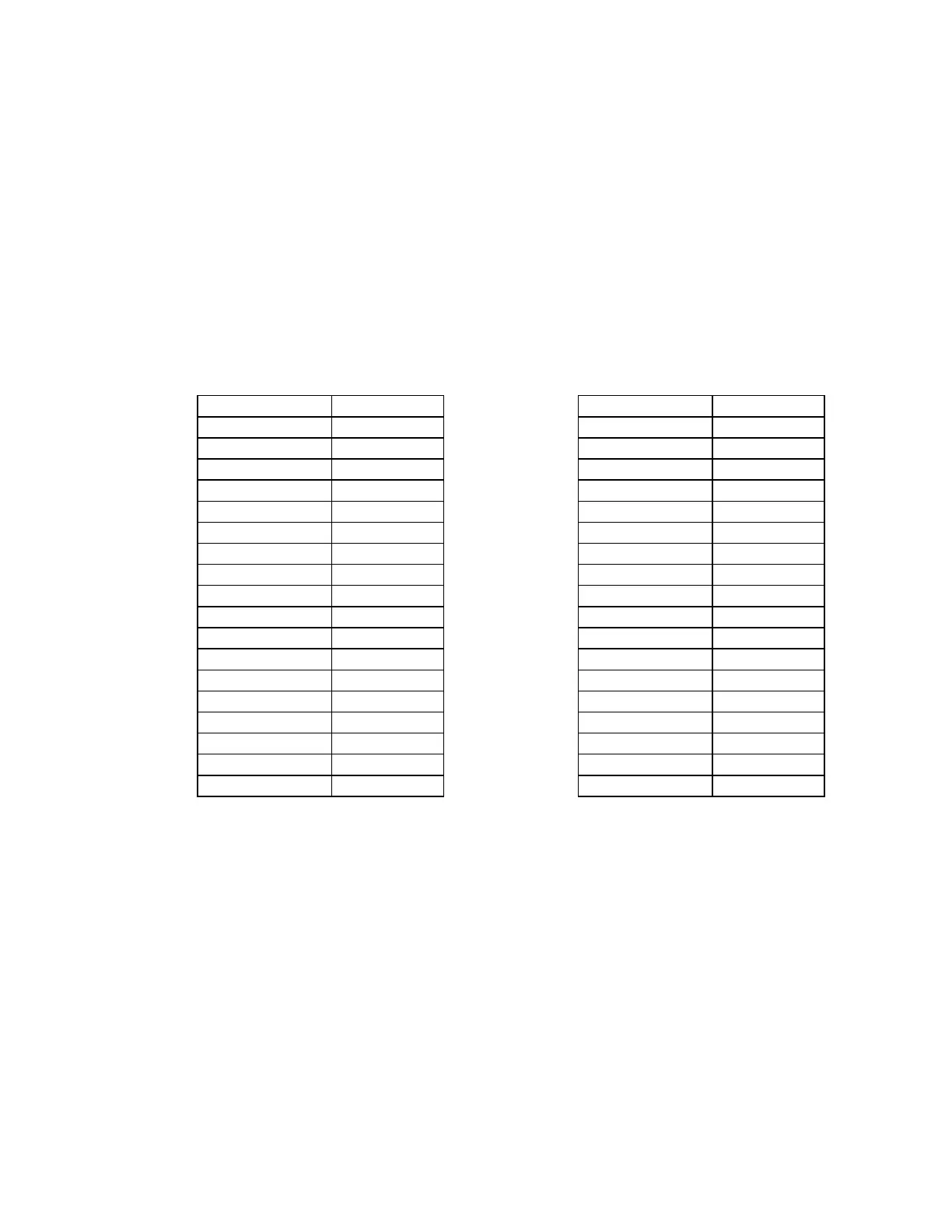

3.3 Service Liquid Requirements

A) Flow Rates

Service liquid flow rates depend on the type of piping arrangement used, the size and operating

speed of the pump, and the allowable temperature rise through the pump. Nominal flow rates

for standard pumps and compressors at normal conditions are given in Table 1.

Service liquid flow rates and the temperature rise are important because of their effect on pump

performance. Too little flow will result in loss of capacity. Too much flow will result in

excessive horsepower requirements.

Service Liquid Flow Rates*

Single Stage Pumps Two Stage Pumps

Pump Model

USGPM

Pump Model

USGPM

PV31040 4 PV32040 4

PV31080 4 PV32080 4

PV31120 6 PV42120 6

PV41160 6 PV42160 6

PV51080 8 PV52120 8

PV51120 8 PV52160 8

PV51160 10 PV52200 10

PV51200 11 PV62160 20

PV61255 20 PV62240 24

PV61335 25 PV72200 30

PV71300 30 PV72300 30

PV71400 30 PV72400 30

PV81360 45 PV72500 35

PV81460 50 PV82350 35

PV81560 55 PV82450 40

PV91540 100 PV82550 45

PV91670 100 PV92540 100

PV92670 100

* Flowrates apply to PV or PC design. For units in m

3

/hr, multiply USGPM by 0.227

Table 1

B) Flow Control

If a flow device is not used to measure the service liquid quantity to the pump, a regulating

valve and compound gauge in the service liquid line can be used to approximate the flowrate.

For pump operating pressures between atmospheric and 400 mmHgA, the reading on the

compound gauge should be in the range of 2" HgV to 5 psig (709 mmHgA to 0.35 barg). For

operating pressures below 400 mmHgA, the compound gauge reading should be in the range of

15" HgV to 2 psig (379 mmHgA to 0.14 barg). This method is only an approximation of the

service liquid quantity. The actual operating conditions will dictate the amount of sealant liquid

required and also the compound gauge reading.

Loading...

Loading...