Graham Corporation

26

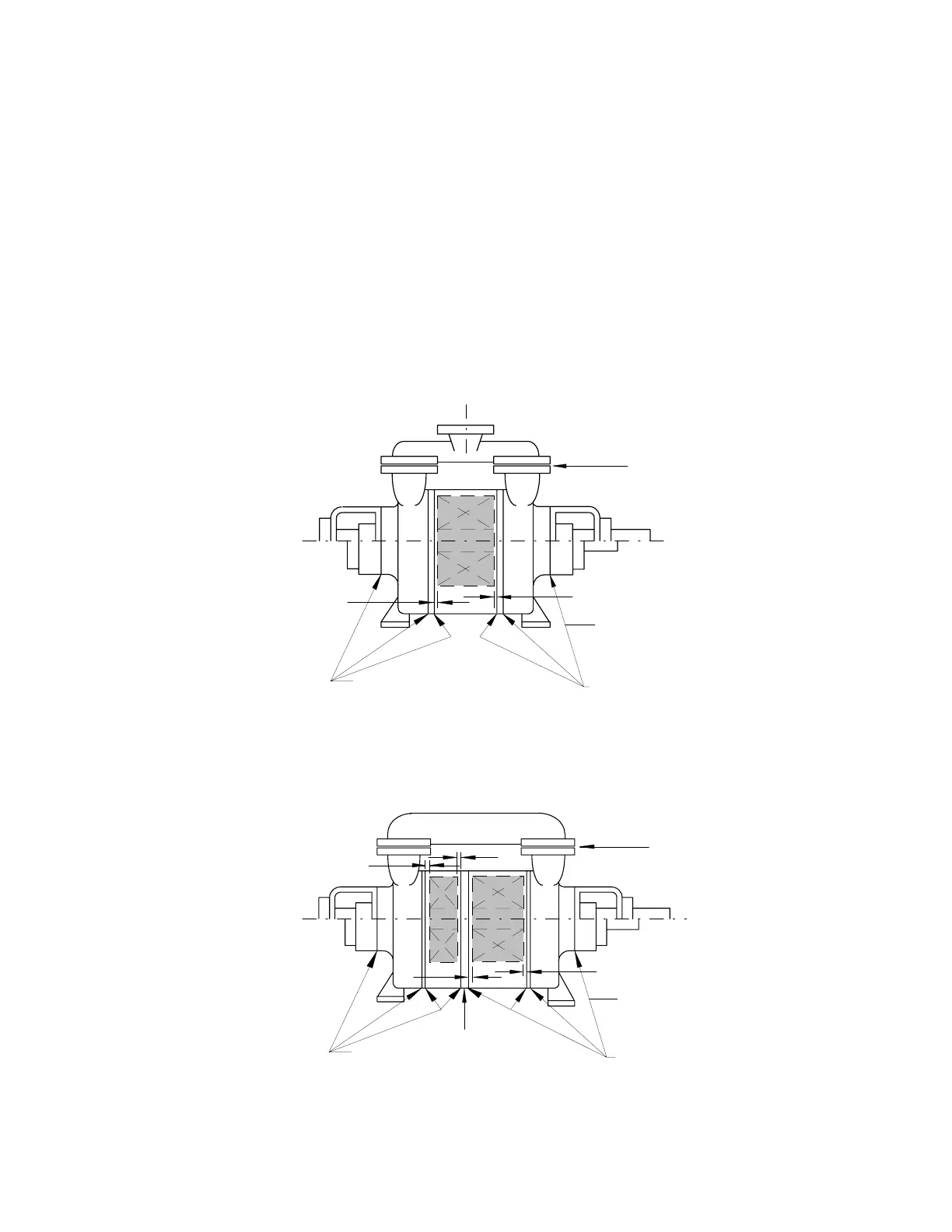

A) Gasketed Pumps

The critical impeller end clearance locations and typical gasket locations are shown in Figures 8

and 9. The gaskets between the impeller casings and the end plates determine the impeller end

clearances. Check and record the thickness and quantity of these gaskets at each joint when

dismantling. The gaskets may be held in place with grease during re-assembly. The gasket

thicknesses used on pumps of standard materials of construction are 0.008" to 0.010" (0.2 to

0.25 mm). The gasket thicknesses used on high alloy pumps are 0.015" to 0.018" (0.38 to 0.46

mm).

Do not use joint sealing compound to replace a gasket as the clearances in the pump will be

affected.

Gaskets

Gaskets

Series 1

Series 2

Single Stage

Figure 8

Series 2 Only

Both Ends

*

*

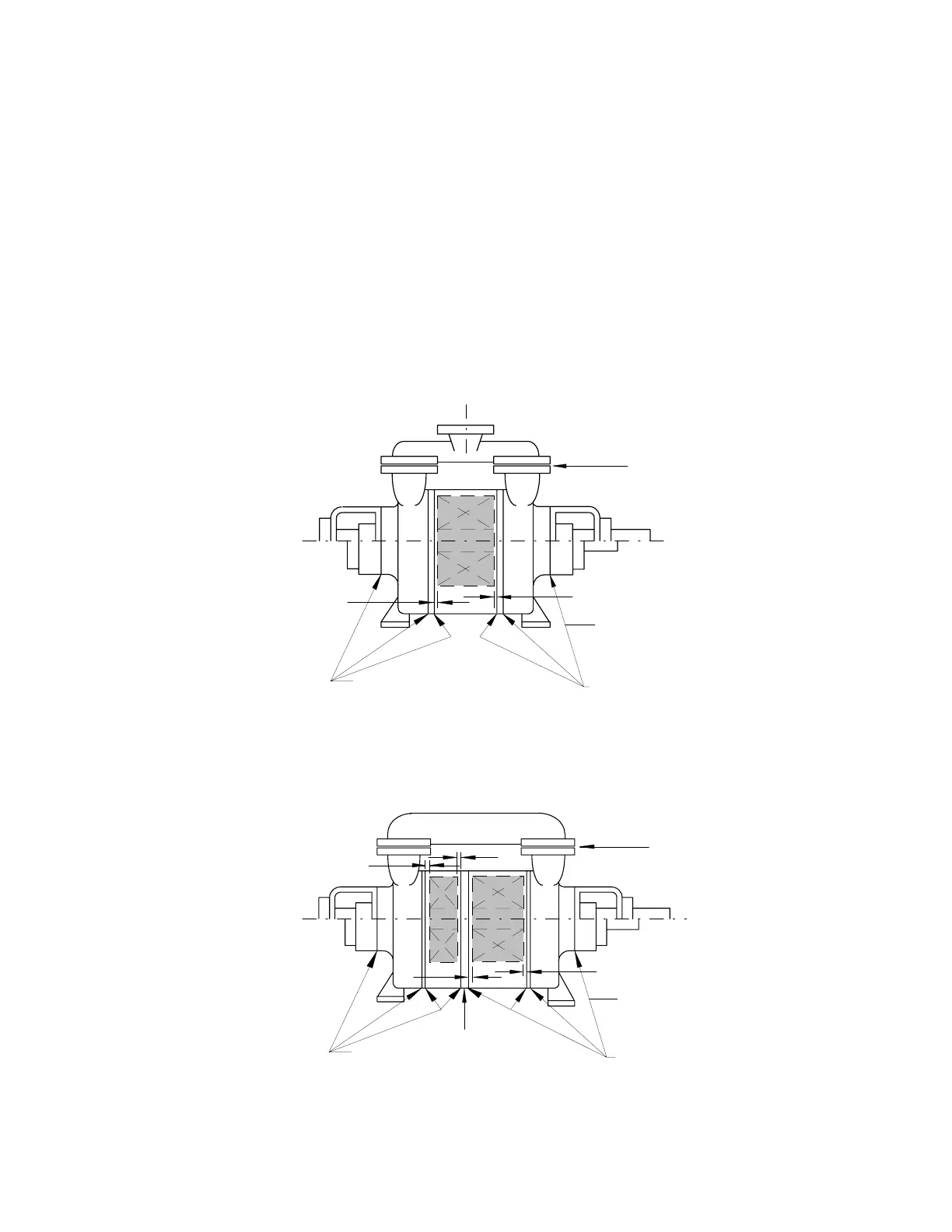

Gaskets

Gaskets

Series 1

Series 2

Two Stage

Figure 9

Gasket for two piece

interstage casing design

Gaskets

Series 2 Only

Both Ends

*

*

*

*

Gaskets

* Impeller clearance locations.

Loading...

Loading...