power supply outputs evaluated under load until

satisfacto-

v

capacitance values are found. Most engineering compa-

nies use a mathematical approach for the initial design

work, and then verify the design by building and testing a

prototype. Developments in computers and software allow

tests using computer simulated prototypes, with savings in

engineering time and expense.

A value of 1000

uF

was selected for the capacitive filter of

the positive variable supply in the

Graymark

808. The se-

lection of this value was based on further calculations.

CONSTRUCTION

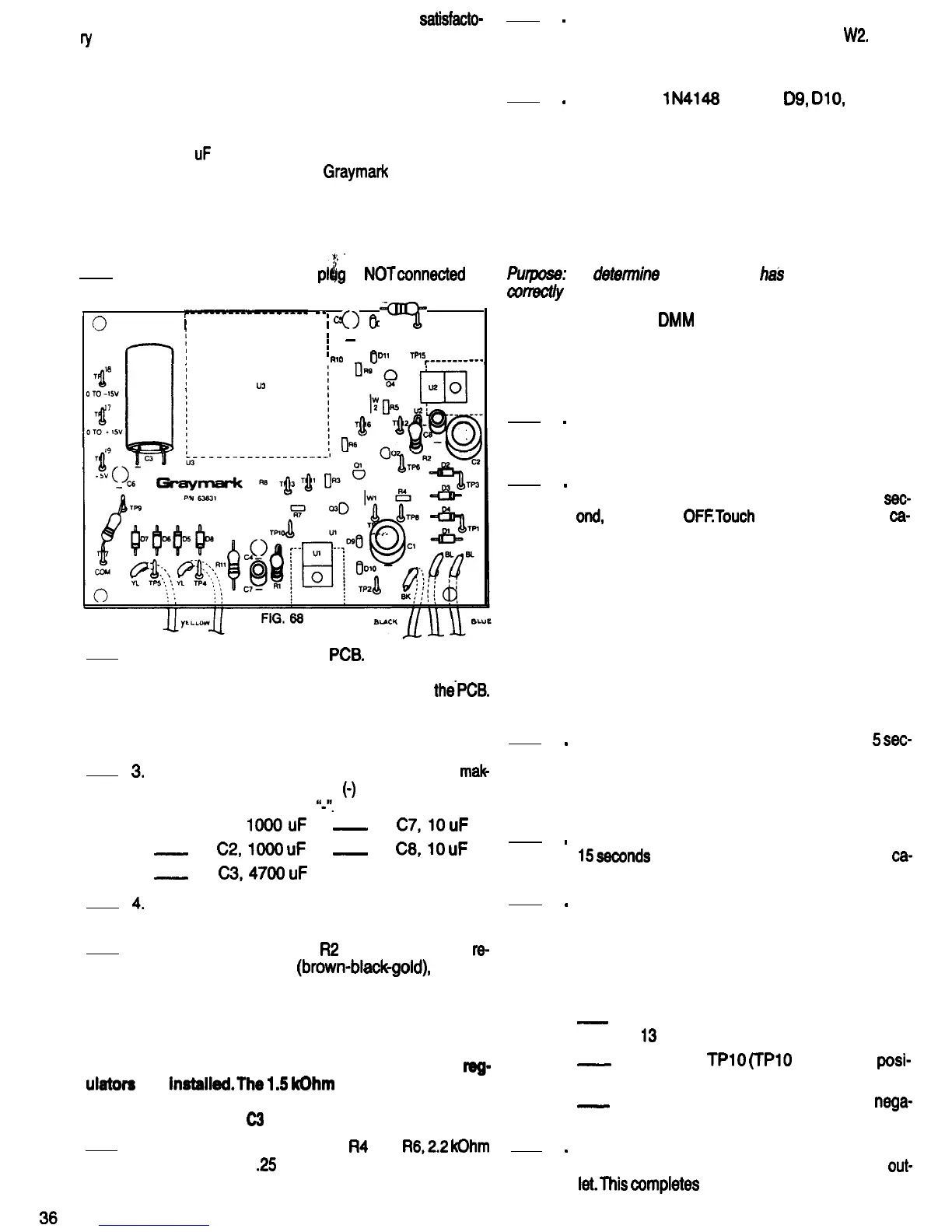

Refer to Fig. 68 for the following steps.

,

1.

Be sure the 808 power

pl$g

is

NOTconnected

to

a power outlet.

r--0-----------

--

I

;

cs

I

I

0

012

Rl2

0

=Fi=

0

I

I

-

I

I

,

RlO

011

lPl5

r----------

U3

2. Mount diode D2 on the

PCB.

Be sure that the

banded end of the diode is oriented the same as

the diode outline that is silkscreened on

thePCB.

Using a heat sink as shown in Fig. 40, solder the

diode leads to the PCB. Cut off any excess lead

length.

3.

Mount the following capacitors on the PCB,

mak

ing sure that the negative

(0)

leads are inserted

into the holes marked

“J’.

-A. Cl,

IOOOuF

_

D.

C7,lO

uF

-

B.

C2,lOOO

uF

-

E.

C8,lO

uF

-

C.

C3,4700

uF

4.

Solder all the capacitor leads to the PCB and cut

off any excess lead lengths.

5. Mount resistors RI and

R2

on the PCB. Both

re-

sistors are 1 Ohm

(brown-blackgold),

1 Watt.

Solder the resistor leads to the PCB and cut off

any excess lead length.

NOTE: The following components are being mounted

on the PCB at this time to serve as bleeder resistors

for capacitors Cl and C2 until the variable voltage

reg-

ulators

are

instaiied.The

1.5

kOhm

test resistor which

was connected to TP7 and TP9 earlier serves as a

bleeder for capacitor

C3

until regulator U3 is installed.

6.

Mount and solder resistors

R4

and

R6,2.2

kOhm

(red-red-red),

.25

Watt, on the PCB. Cut off the

excess lead length. Save one of these leads for

the next step.

7

.

8

.

Bend the piece of wire saved from the last step

into a “U” shape, and use it for Jumper

W2.

insert

this jumper wire from the component side of the

PCB. Solder and cut off any excess lead length.

Mount the

lN4148

diodes

D9,

DIO,

Dll and

D12 on the PCB. These diodes are smaller than

the rectifier diodes installed earlier. Be sure that

the banded ends of the diodes are oriented as

shown on the diode outlines printed on the PCB.

Using a heat sink, as shown in Fig. 40, solder the

diodes to the PCB. Cut off any excess lead

PCB TEST

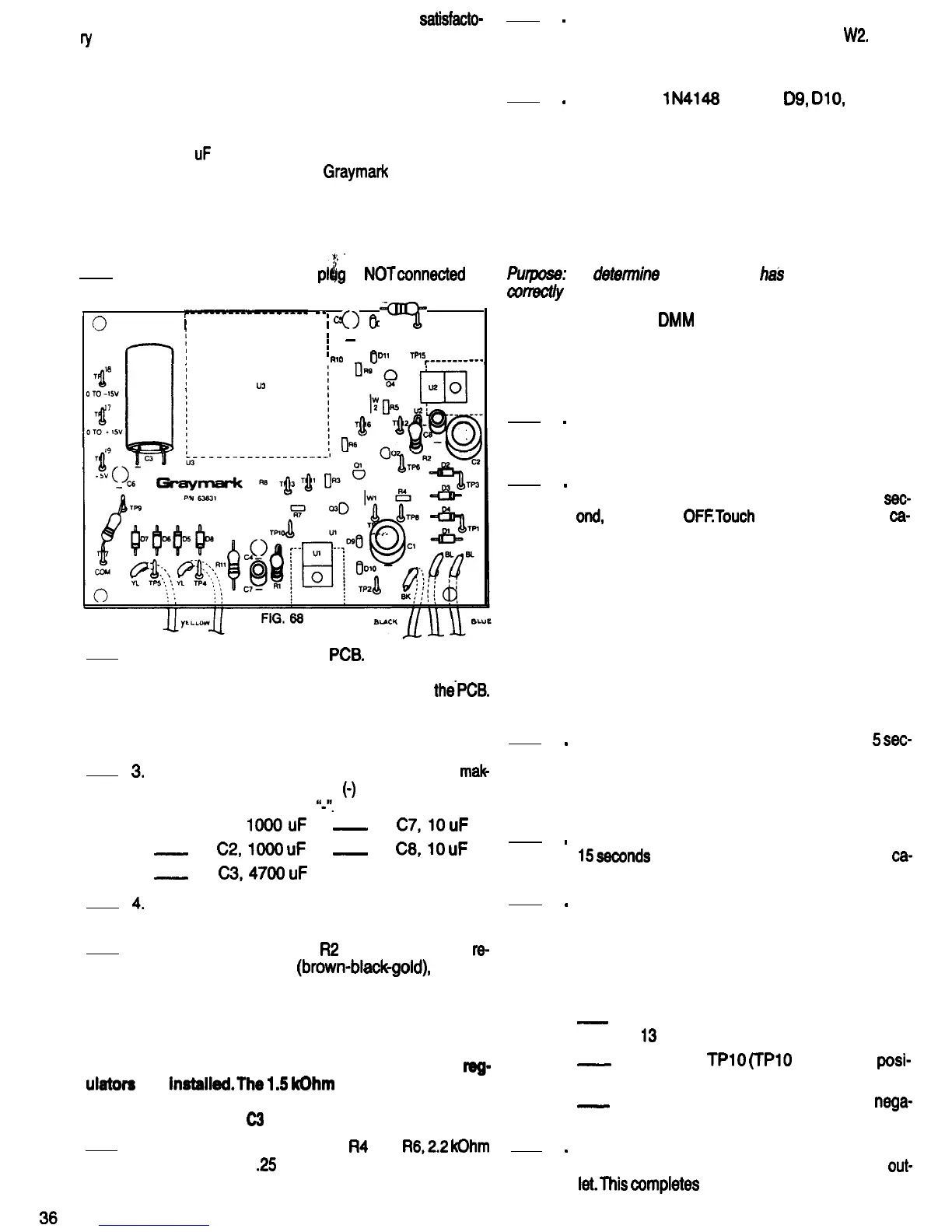

Pwpose:

To

detemine

that the PCB

ha3

been assembled

conectly

up to this point.

Equipment: VOM or

DMM

1

.

2

.

3

.

4

.

5

.

6

.

Watch with second hand or digital readout.

(Counting out loud “One thousand one, one

thousand two . . .

one thousand thirteen” etc.,

would be accurate enough for these tests.)

Review rule 9 of BUILDING YOUR POWER

SUPPLY BREADBOARD that appears earlier in

this manual.

With the 808 power plug connected to a power

outlet, turn the 808 power switch ON, wait 1

sec.

and,

and turn it

OFFTouch

all the diodes and

cam

pacitors C7 and C8 with your finger to tell if any

of them are warm or hot. Bigger components

take longer to heat up if something is wrong. By

checking smaller components after a short pow-

er ON period, even if something is wrong the

components probably will not be damaged, and

will work satisfactorily after the fault is wrrected.

If any of the wmponents called out above are

warm, something is wrong. Check the PCB care-

fully, and consult with your instructor if

necessary.

Repeat step 2, leaving the power ON for

5

sec.

onds. Recheck all the diodes, and capacitors C7

and C8 to tell if they are warm. In addition, touch

capacitors Cl, C2 and C3 to tell if they are getting

warm.

Repeat step 2 again, leaving the power ON for

15

sewnds

this time. Recheck all diodes and

ca-

pacitors for heating.

If none of the diodes or capacitors heated up in

steps two through four, power up the 808 again

and measure the dc voltage between the pairs of

test points listed below. For an input line voltage

of from 105 to 125 Volts, the voltages you meas-

ure should be within the ranges listed below.

-

A. TP7 and TPQ (TPQ should be positive),

13

to 16 Volts dc.

-_

B. TP7 and

TPlO

(TPlO

should be

posi-

tive), 25 to 31 Volts dc.

_

C. TP7 and TP12 (TP12 should be

nega-

tive), 25 to 31 Volts dc.

Turn OFF the power switch of the 808 Power

Supply, and remove its power plug from the

out-

let.This

wmpletes

the FILTER SECTION. Have

your instructor initial your progress guide.

Loading...

Loading...