Repeat step 2 again, this time leaving the power

ON for

15

s.econds.

If none of the components heated up in the previ-

ous

steps1

power up the 808 again. Measure the

dc voltage between test points TP7 and TP17.

TP17 should be positive, and the voltage should

be between 12.7 and 15.8

Volts.The

reason that

a range of voltages is given is that the tolerances

of a number of components can affect the regula-

tor output voltage. If the voltage is not in this

range, check resistor

R7

and the 3.9

kOhm

resis-

tor installed temporarily between TP13 and

TP14. Make sure they are the correct resistors

for these locations. Consult with your instructor

if necessary.

Turn OFF the 808 power switch and remove the

power plug from the power outlet.

Mount 10

mF

capacitor C4 on the PCB, making

_

4

.

sure that the negative lead is inserted in the hole

marked

“J’.

Solder the capacitor leads to the PCB

and cut off any excess length.

5

.

Locate the positive variable voltage regulator, U 1

(LM317),

one of the small heat sinks, a 3 x 8mm

machine screw, a 3mm split lock washer and a

3mm hex nut.

Bend the three leads of the

LM317

regulator as

shown in Fig. 73. A long nose pliers is

agood

tool

to use for this.

Refer to Fig. 74. Mount the

LM317

regulator

and heat sink on the

l%B,

using the hardware

called out in step 5.

Graymark

recommends the

use of heat sink compound on the surfaces of

the voltage regulators and heat sinks where

they contact each other.

6

.

4

.

5

*

6

.

.

7

.

8

.

9

.

Before tightening the machine screw and nut that

holds the heat sink and regulator to the PCB,

ro-

tate the heat sink on the machine screw so that

its cooling fins are oriented as shown in Fig. 72.

Then tighten the machine screw and nut.

Solder the regulator leads to the PCB, using a

small alligator clip heat sink on each lead be-

tween the plastic regulator package and the top

surface of the PCB. Cut off any excess lead

length.

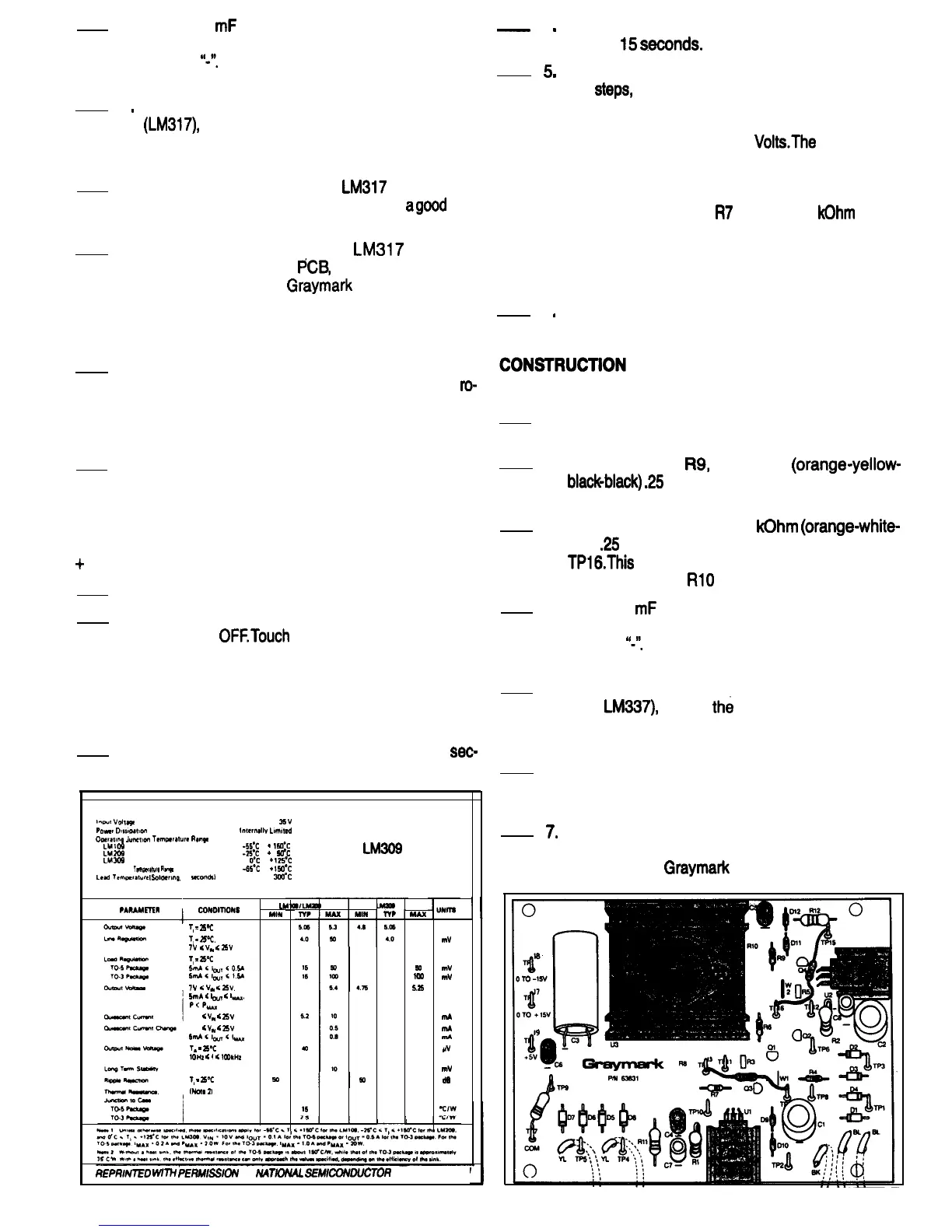

Refer to Fig. 72 for the following steps.

1. Be sure the 808 power plug is not connected to

a power outlet.

2. Mount resistor

R9,

340 Ohm

(orange-yellow-

blackblack)

.25

Watt 1%, on the PCB. Solder the

leads to the PCB and cut off any excess length.

3. Solder the leads of a 3.9

kOhm

(orange-white-

red)

.25

Watt test resistor to test pointsTP15 and

TPl6.This

resistor temporarily takes the place of

variable resistor

RlO

for test purposes.

+

15 VOLT REGULATOR TEST

1. Connect the 808 power plug to a power outlet.

2. Turn the 808 power switch ON, wait 1 second

and turn it

OFETouch

the components that were

installed in the construction steps that were just

completed. If any of these components are

warm, there is something wrong. Check the PCB

and components carefully, and consult with your

instructor if necessary.

4. Mount 10

mF

capacitor C5 on the PCB, making

sure that the negative lead is inserted in the hole

marked

“-“.

Solder the capacitor leads to the PCB

and cut off any excess length.

5. Locate the negative variable voltage regulator

(U2,

LM337),

one of

th&

small heat sinks, a 3 x

8mm machine screw, a 3mm split lock washer

and a 3mm hex nut.

3. Repeat step 2, leaving the power ON for 5

sec.

onds this time.

6. Bend the three leads of the LM337 regulator as

shown in Fig. 73. A long nose pliers is a good tool

to use for this.

7*

Refer to Fig 74. Mount the LM337 regulator and

heat sink on the PCB, using the hardware called

out in step 5.

Graymark

recommends the use of

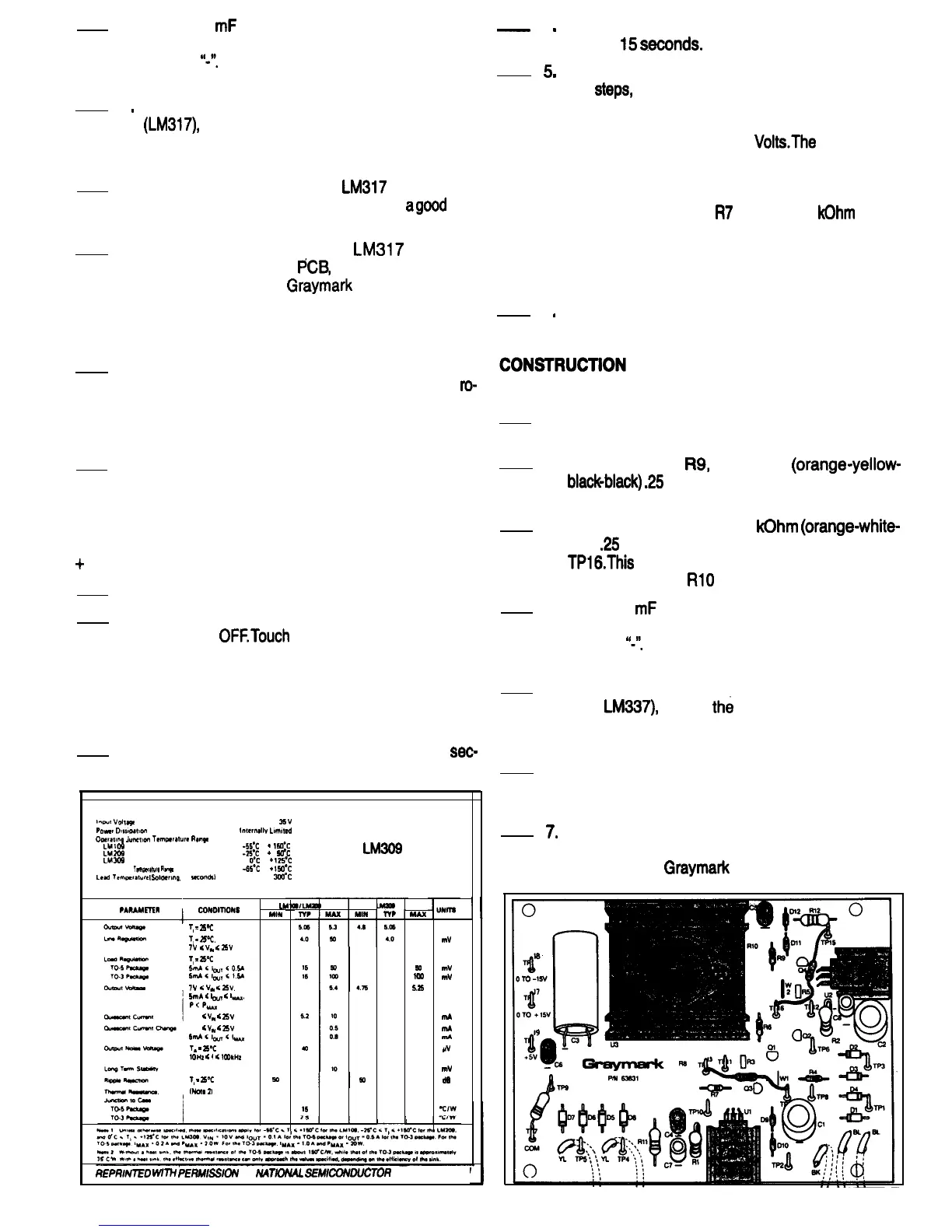

Absolute Maximum Ratings

lvu~

VOllege

35v

poww

ow~oat~on

lntemali~

Lomated

Ooefatm9

Jwurwn

Temperature

Ran9e

LMlO9

-WC

to

+

15oY

IA209

-2sY

to

+

1

50°c

LM309

LM309

O’C

to

+

125OC

SPECIFICATIONS

Storage

Temperawe

Range

-65’C

to +150°C

head

lempratuw

Golciew19.

10

seconds)

Electrical Characteristics

300°C

T

T

15

15

5.2

40

15

2.5

u

MIN

47

4.6

50

,

-I-

V

mV

mV

mV

V

mA

mA

mA

PV

mV

d6

cofuomotus

1,

=

25T

1,

=2Pc,

7v

<

VW

<

25v

T,

=

25QC

SmA<lwT<O%

51?lA<lw,~15A

?V

<

VW

G

25v.

5mA

6

b,,,

6

I-.

P<P_

7v

<

VW

<

25v

7v

<

v*

fi

25v

5mAGl~Gl_

7.

=

25.T

1OHz

<

f

<

1tXIkHz

1,

=

25T

(NOW

2)

PARAMETER

MAX

5.2

50

50

100

5.25

10

0.5

0.0

20

REPRIUTED

WITH

PERMSSION

OF

M4TlONAL

SEMCONDUCTOR

CORPORATION

FIG. 71

FIG. 72

38

Loading...

Loading...