is connected, but before the voltage regulator. is able to

Equipment:

DVM

or

DMM

compensate for this change in load resistance.

It

takes much longer to describe the operation of a voltage

1

.

regulator than it takes for the regulator to

operate.There

is

some time delay from the instant that a load change or

input voltage change takes place and causes the output

voltage to change until the voltage regulator is able to

-

2

.

compensate and restore the correct output voltage. This

time delay occurs mostly in the op amp and Darlington

3

.

transistor circuitry. Figure 82 is from the

LM309

specification sheets, and illustrates the time required for

the

LM309

regulator to respond to a load change. Notice

that it is a very short time, about 1 micro second.

The output filter capacitor for the fixed supply, C6, reduces

4

.

the amplitude of these voltage spikes. C6 has a

capacitance of 10

mF

It does not need to have a large

-

5

.

capacitance like C3, the input filter capacitor, because of

the short periods of time it must provide or absorb electrical

energy to keep the output voltage constant. Look again at

Fig.

63.The

time that the input filter capacitor must provide

electrical energy is about 6 milliseconds, which is 6000

times as long as 1 microsecond.

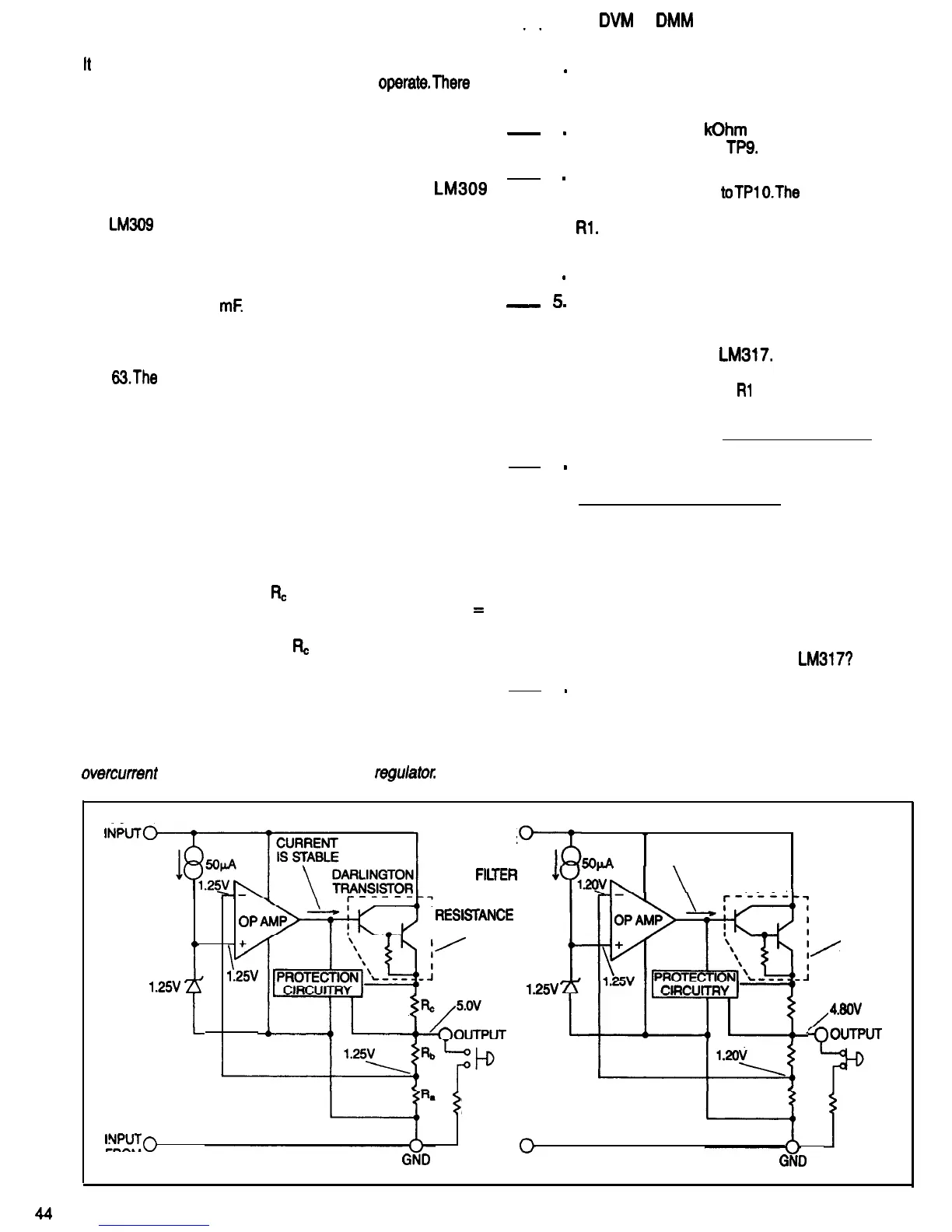

The circuitry symbolized by the rectangle labeled

PROTECTION CIRCUITRY can divert the op amp output

current away from the base of the Darlington transistor.

Normally, when the op amp output moves in the positive

direction, we want to increase the current flowing through

the voltage regulator and load resistor. But when this

current reaches the maximum value the regulator can

safely handle, we don’t want it to increase any more.

The voltage across resistor

Rc

is directly proportional to the

current flowing through it. (Ohm’s law again, voltage

=

current x resistance. As the output current of the regulator

increases, the voltage across

R=

increases as well. When

this voltage reaches a level that indicates the maximum

safe current is flowing, the protection circuitry begins to

divert current away from the Darlington transistor base.

OVERCURRENT PROTECTION EXPERIENCE

6

.

7

.

Clip Lead

Be sure that the 808 power plug is NOT

connected to a power outlet. Refer to Fig. 83 for

the following steps.

Remove the 1.5

kOhm

test resistor which is

soldered toTP7 and

TP9.

Connect the positive meter lead toTP8 and the

negative meter lead

toTP1

O.The

meter will read

the voltage across the current sensing resistor

Rl.

Set the meter range selector to read a DC

voltage of 2.5 Volts.

Connect the 808 power plug to a power outlet.

Turn the 808 power switch ON. While observing

the meter, connect the clip lead from TP7 to

TP17. This is a short circuit across the positive

variable regulator,

LM317.

This represents a

heavy overload for the power transformer and

current sensing resistor

Rl

. Read the meter and

quickly remove the clip lead. Write down the

meter reading here.

Volts

Using Ohm’s law, calculate how much current is

flowing through the regulator.

Amps. Notice that

when using a 1 Ohm current sensing resistor,

The voltage across the resistor in Volts is the

same as the current flowing through the resistor

in Amps. The same correspondence occurs

when voltage is in millivolts, the current is then

in milliamps. How does the current you

measured compare to the value given on the

National Semiconductor Electrical Characteris-

tics specification sheet for the

LM317?

Turn OFF the 808 power switch and remove the

power plug from the power outlet. Disconnect the

clip lead and the meter test leads.

Purpose: To observe the operation of the internal

Just how hot a voltage regulator becomes when it is

overcurrent

limiting function of a voltage

regulatotz

operating depends on a number of variables. The input

POSITIVE

INI+*

FROM

FILTER

POSITIVE

INPUT

FROM

FILTEI

I

CURRENT

_WllA

WILL INCREASE

.

I

3

JU

vw’aw.

--t/h

I

\

DARLINGTON

TRANSISTOR

I

1

1

1.25V

RESISTANCE

WILL

DECREASE

/

RESIS’KANCE

IS STABLE

OP

A+

7

\’

1.25V

1.25V

I!

/

480V

-()OUTPUT

LOAD

RESISTOR

NEGATIVE

l%PUTo

FROM

FILTER

LOAD

RESISTOR

NEGATIVE INPUT

GND

FROM FILTER

GND

FIG. 81

44

Loading...

Loading...