3

.

4

.

5

.

6

.

FIG.

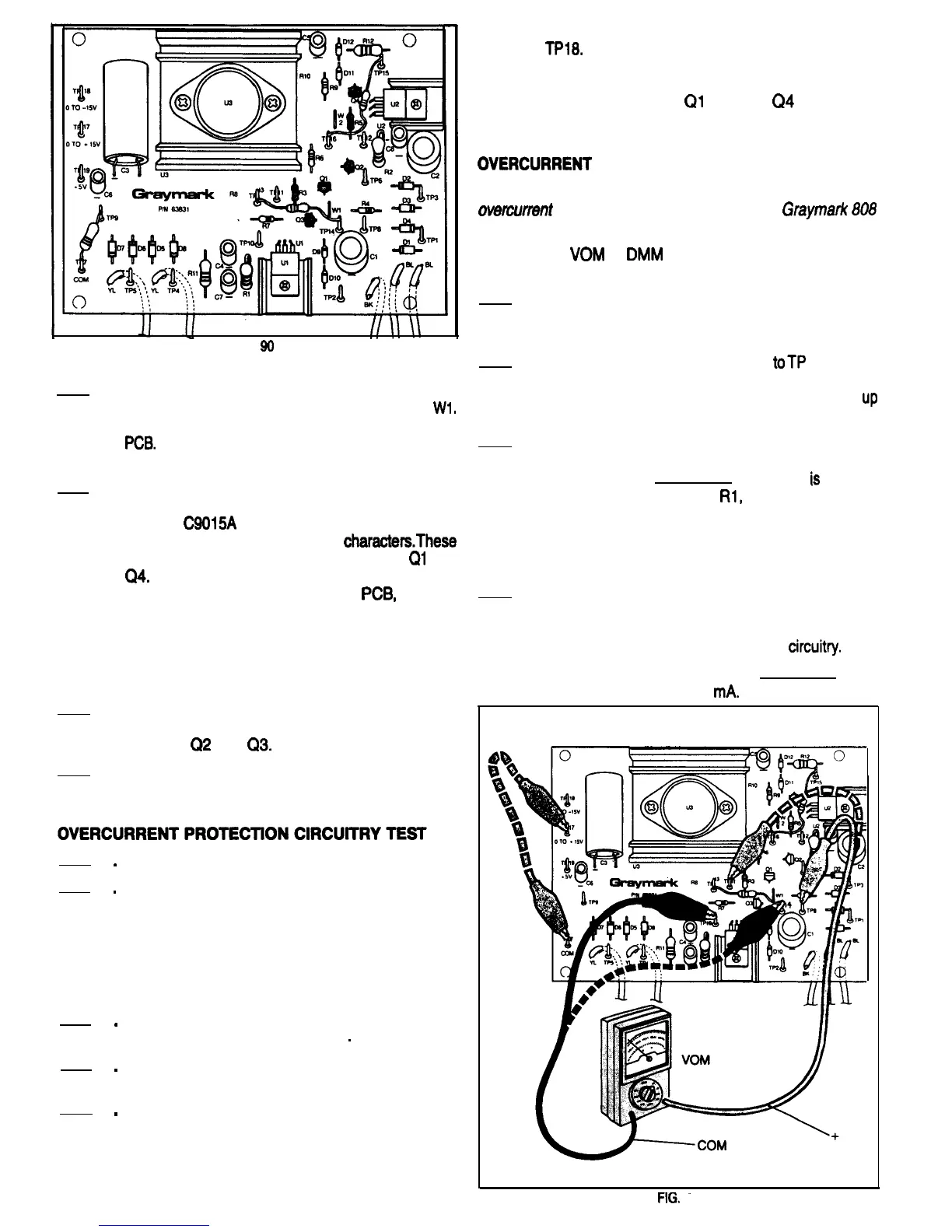

90

pieces of wire for the next step.

Bend the piece of wire saved from the previous

step into a U shape and use it for jumper wire

Wl

.

Insert this wire from the component side of the

PCB.

Solder it to the PCB and cut off any excess

length.

Locate the two transistors that are marked 9015.

There may be other numbers or letter as well,

such as

CQOl5A

QC, but the numbers 9015 will

appear within the sequence of

charactersThese

are the PNP transistors and are used for

Ql

and

C4.

Spread the leads to form a triangle, and

mount these transistors on the

PCB,

making

sure that they are oriented the same as the D

shaped transistor outlines that are silk screened

on the PCB. Solder the leads to the PCB, using

a heat sink as shown in Fig. 40 on each lead as

you solder it.

Repeat Step 4, using the transistors marked

9014. These are the NPN transistors and are

used for

Q2

and

Q3.

This completes the construction of the external

protection circuitry. Have your instructor initial

your progress guide.

1

.

2

.

3

.

4

.

5

.

Connect the 808 power plug to a power outlet.

Turn the 808 power switch ON, wait 1 second

and turn it OFF touch the components that were

installed in the construction steps just

completed. If any of these components are

warm, there is something wrong. Check the PCB

and components carefully, and consult with your

instructor if necessary.

Repeat step 2, leaving the power ON for 5

seconds this time.

.

Repeat step 2 again, leaving the power ON for

15 seconds this time.

If none of the components heated up in the

previous steps, power up the 808 again.

Measure the DC voltage between test pointsTP7

and TP17. TP17 should be positive,and the

voltage should be between 12.7 and 15.8 Volts.

Then measure the DC voltage betweenTP7 and

TPl8.

TP18 should be negative and the voltage

should again be between 12.7 and 15.8 Volts. If

these voltages are not within these ranges,

check transistors

Ql

through

CJ4

for proper

location and orientation. Consult with your

instructor if necessary.

OVERCURRENT

PROTECTION EXPERIENCE

Purpose: To demonstrate the operation of the external

overcurrent

protection circuitry used in the

Graymark

808

Power Supply

Equipment:

VOM

or

DMM

Clip Lead

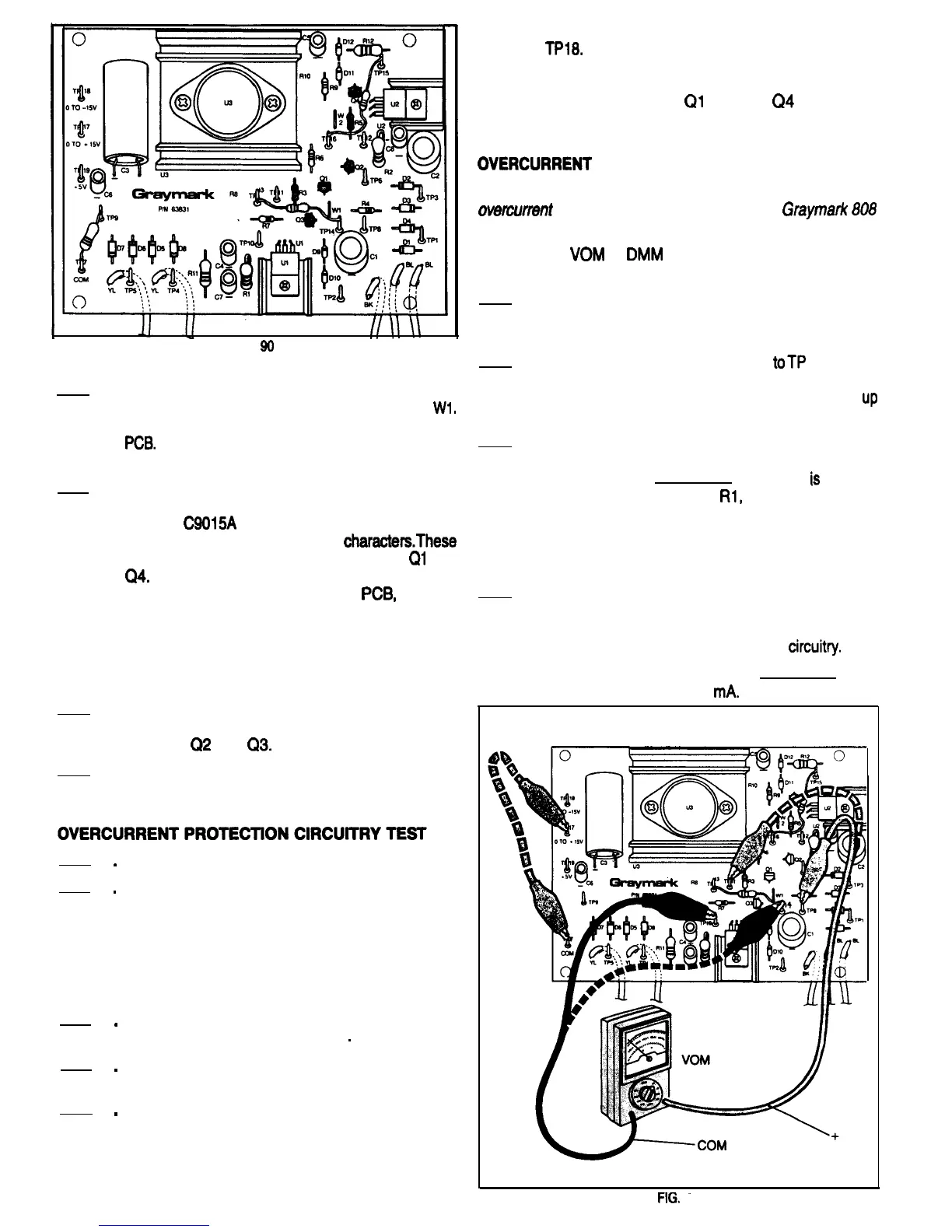

1.

Be sure that the 808 power plug is not connected

to a power outlet. Refer to Fig. 91 for the following

steps.

2. Connect the positive meter lead

toTP

8 and the

negative meter lead to TP 10. Set the meter

range selector switch to a range that will read

up

to 1 Volt DC.

3. Connect the 808 power plug to an electrical

outlet and turn the power switch ON. What is the

meter reading?

The meter

is

reading

the voltage drop across

Rl,

the 1 Ohm current

sensing resistor. What is the current flowing

through the resistor? Use the short cut way of

calculating the current value that was discussed

earlier in this manual.

4. Connect the clip lead to TP7 and TP17. This

provides a very low resistance load for the

positive variable power supply, and will activate

its external overcurrent protection

circuitv.

How

much current is flowing now?

It should be about 500

mA.

FIG.

91

4

Loading...

Loading...