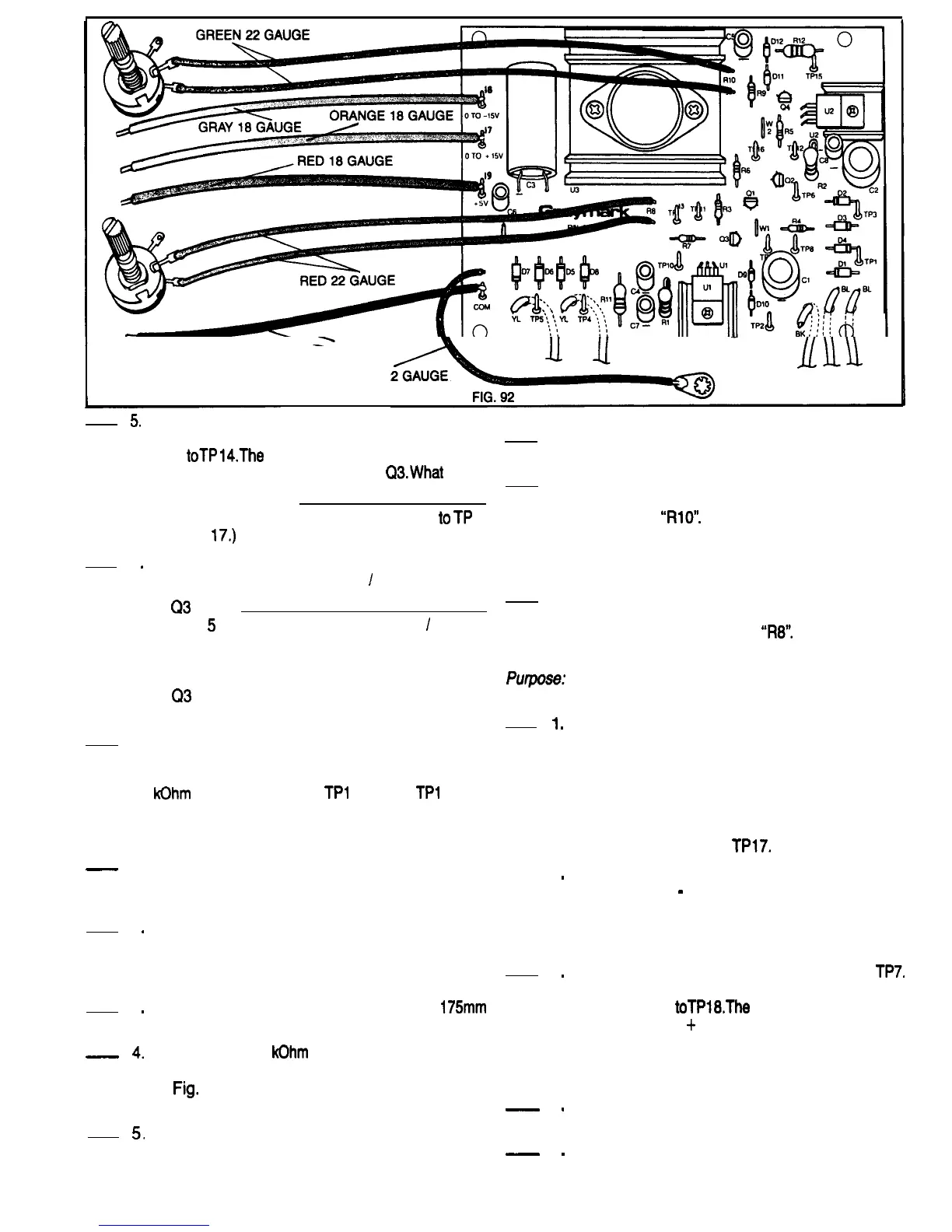

BLACK 18 GAUGE

GREEN 2

5.

Disconnect both meter leads and reconnect the

be used.

6

.

positive meter lead to TP 11 and the negative

lead

toTP

14.The

meter will now read the voltage

between the emitter and base of

Q3.What

is the

meter reading now?

(The clip lead should still be connected

toTP

7

and TP

17.)

Remove the clip lead fromTP7 and TP 17. What

is the voltage across the base

/

emitter junction

of

Q3

now?

VOLTAGE CONTROL OPERATIONALTEST

Pupose:

To determine that the external voltage control

circuitry is working properly

In step

5

the voltage across the base

/

emitter

junction was more than 0.5 Volts, and current

was flowing from the collector to the emitter. In

this step the voltage from the base to the emitter

of

Q3

was very low, so there was almost no

current flowing from the collector to the emitter.

7. Turn OFF the 808 power switch and disconnect

the power plug from the power outlet. Remove

the test clip and meter leads. Remove the two 3.9

kOhm

test resistors from

TPI

3, TP14,

TPI

5 and

TP16.

6. Repeat step 5, this time using the two red wires

and the second potentiometer.

7.

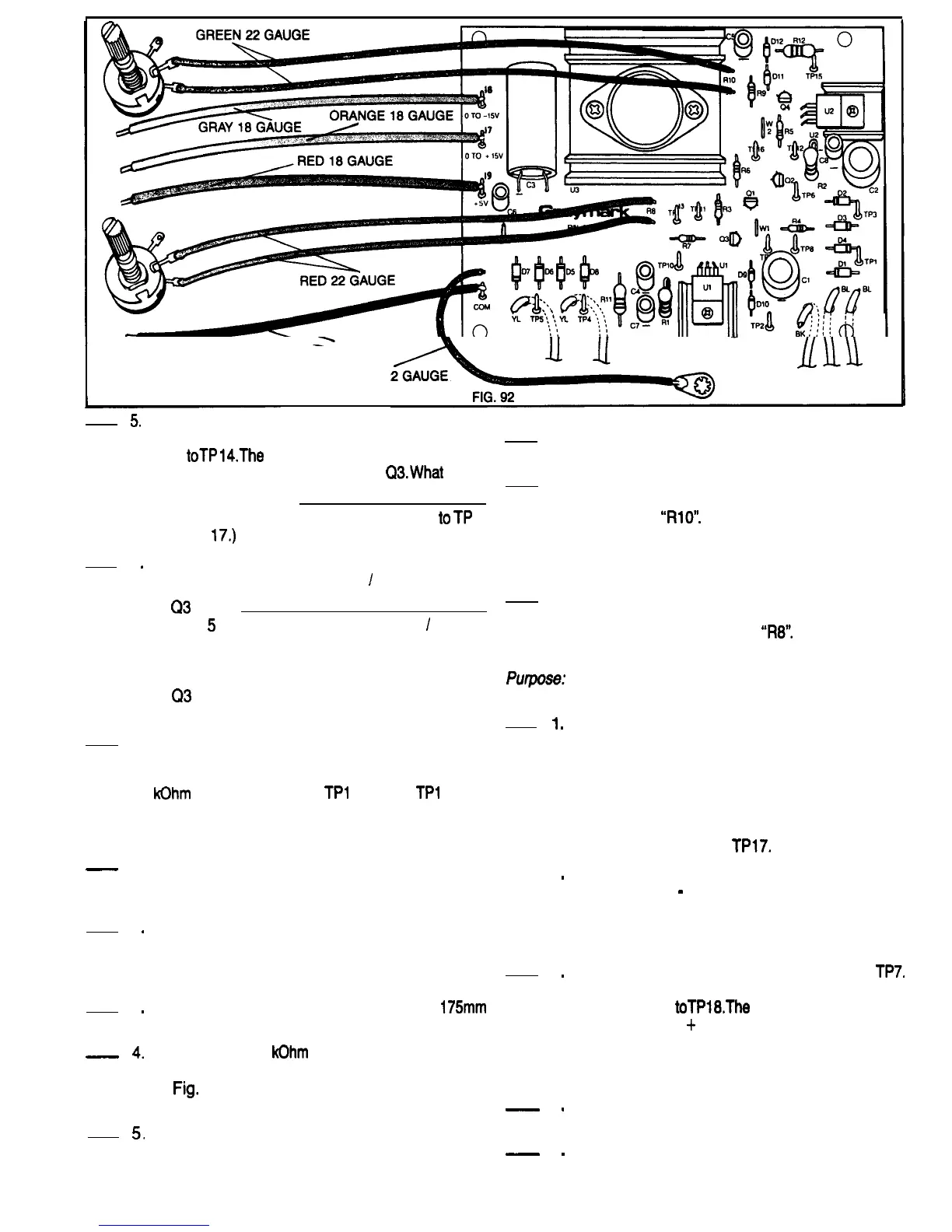

Insert the free ends of the green wires in the PCB

holes that are nearest to the silk screened

designation

“RlO”.

Solder the wires to the PCB

and cut off any excess length. It doesn’t matter

which of the two wires goes into which of the two

holes.

8.

Repeat step 7, this time using the free ends of the

two red wires and the two holes on the PCB

closest to the designation

“R8”.

1

.

CONSTRUCTION

-

1.

2

.

3

.

-

4.

5.

Be sure that the 808 power plug is not connected

to a power outlet. Refer to Fig. 92 for the following

--

2

.

steps.

Cut two 200mm pieces of green 22 gauge wire

and strip 6mm of insulation from all four ends.

Twist the exposed strands of fine wire together

on each end and tin them.

3

.

Repeat step 2, cutting and preparing two

175mm

pieces of red 22 gauge wire.

Locate the two 5

kOhm

potentiometers. Bend the

small metal tab on each potentiometer as shown

in

Fig.

93 so that it won’t interfere when the

potentiometer is mounted on the cabinet top.

_

4

.

Connect and solder the two green wires

prepared in step 2 to one of the potentiometers

_

5

.

as shown in Fig. 93. It is important that the

correct solder terminals of the variable resistors

During this test be careful not to let the terminals

of the potentiometers touch the PCB or any of the

components. Rotate the control shafts of both

potentiometers to the full counter clockwise

position. Adjust the range selector of your VOM

or DMM to measure up to 20 Volts DC. Connect

the negative meter lead to TP7. Connect the

positive meter lead to

TPl7.

Power up the 808. The voltmeter should read

between 0 and

-

0.3 Volts. Rotate the Shaft of the

potentiometer connected to the red wires to the

full clockwise position.The voltmeter should now

read between 15.5 and 20 Volts.

Remove the voltmeter leads fromTP17 and

TP7.

Reconnect the positive meter lead toTP7 and the

Negative lead

toTPl8.The

voltmeter should read

between 0 and

+

0.3 Volts. Rotate the shaft of

the potentiometer connected to the green wires

to the full clockwise position. The meter should

now read between 15.5 and 20 Volts.

Turn OFF the 808 power switch and disconnect

the power plug from the power outlet.

This completes the VOLTAGE CONTROL

OPERATIONAL TEST Have your instructor

initial your progress guide.

50

Loading...

Loading...