FINAL PCB ASSEMBLY

1. Be sure that the 808 power plug is NOT

connected to a power outlet. Refer to Fig. 92 for

the following steps.

2.

Locate the four

15Omm

lengths of 18 gauge wire.

strip 6mm of insulation from each end of each of

the four wires. Twist the fine strands of exposed

wire on each of the ends together and tin them.

Form one of the tinned ends of each of the wires

into a hook shape with a long nose pliers.

Connect and solder these hooked wire ends to

the following test points on the PCB.

-

A. The black wire to TP 7.

-

B.

The red wire to TP 19.

-

C. The orange wire to TP 17.

_

D,

The gray wire to TP 18.

3.

Cut a 1

OOmm

piece of green 22 gauge wire. Strip

6mm of insulation from each

end.Twist?he

small

strands of wire together, and tin both ends.

4.

Connect and solder the

3.5mm

solder lug to one

end of the green wire that you prepared in the

previous step. Connect and solder the other end

of this wire to the PCB. Use the unmarked hole

near TP 7. Cut off any excess wire.

5. This completes the FINAL PCB ASSEMBLY.

Have your instructor initial your progress guide.

CABINET ASSEMBLY

CAUTION!

Be sure that the AC Cord is NOT plugged

into an electrical outlet during this Cabinet

Assem

biy

Section.

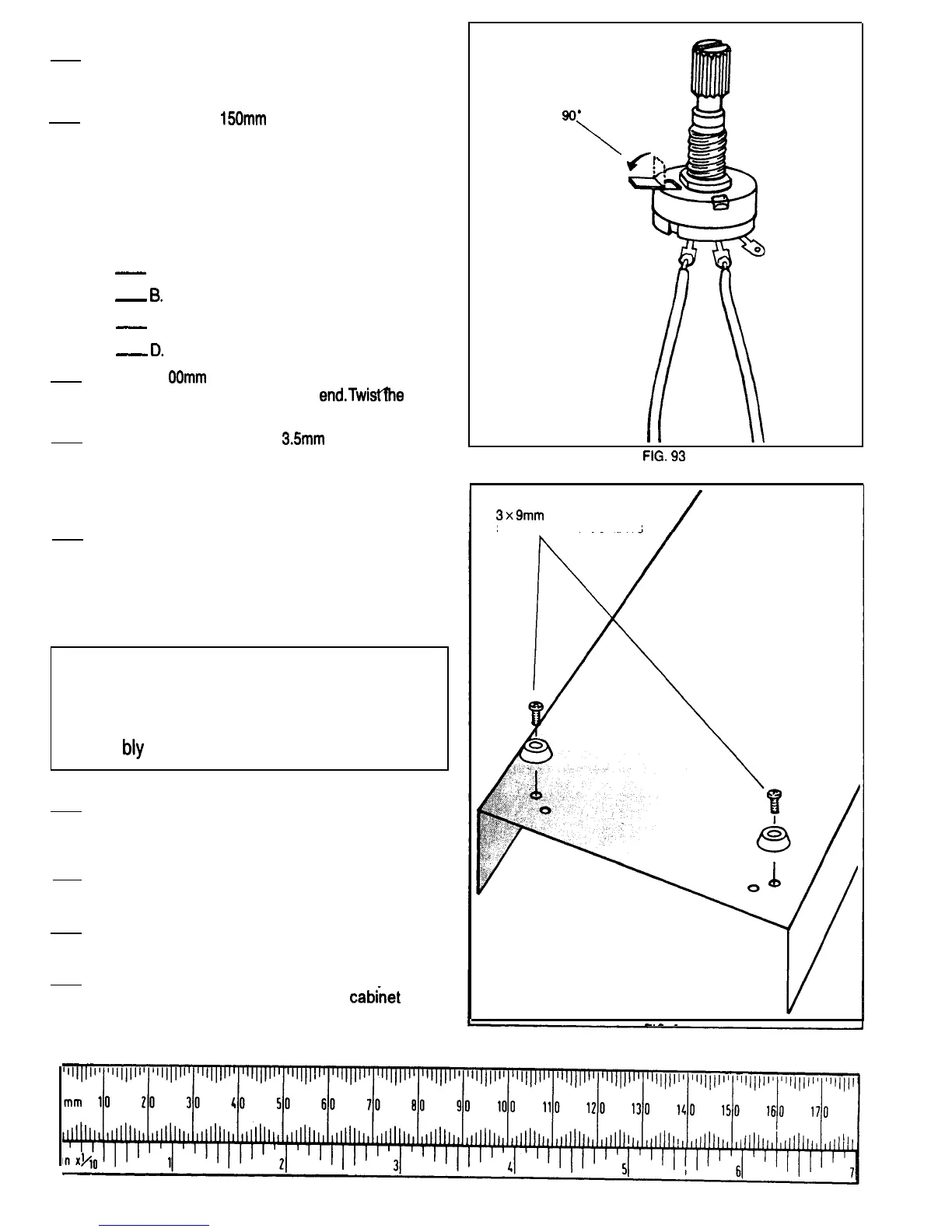

1.

Mount two rubber feet to one end of the cabinet

bottom, using two 3 x 8mm self-tapping screws.

Refer to Fig. 94.

2.

Repeat the previous step for the other end of the

cabinet bottom.

3. Remove the protective plastic from the

breadboard.

4. Place the cabinet top face up on your work

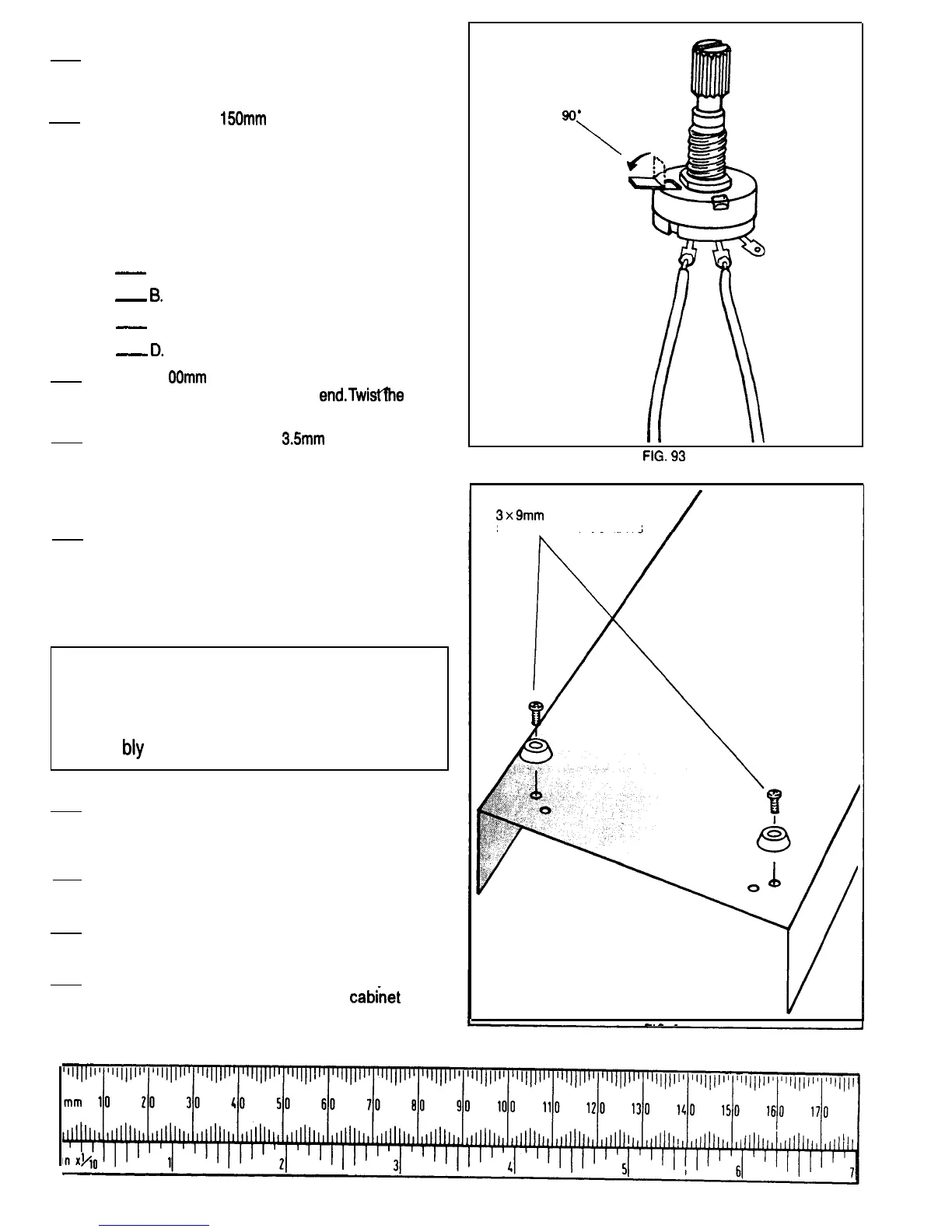

BEND

TAB

90’

\

FIG.

93

3x9mm

SELF-TAPPING SCREWS

-.-

-

FIG. 94

surface, so the printing on the

cabirnet

top is

readable.

Loading...

Loading...