the needle settings suit requirements of the pipe and header you use.

(e) Incorrect ignition timing and failing spark plugs, which will result in twisted crankshafts and

therefore lower RPM.

10. If the engine runs roughly or vibrates strongly:

(a) Check if the low needle is too rich

(b) Check balance of the propeller and spinner

(c) Make sure the engine mount bolts are well tightened.

(d) Check if the ignition timing is correct.

(e) Check structure of the engine box and firewall on the plane.

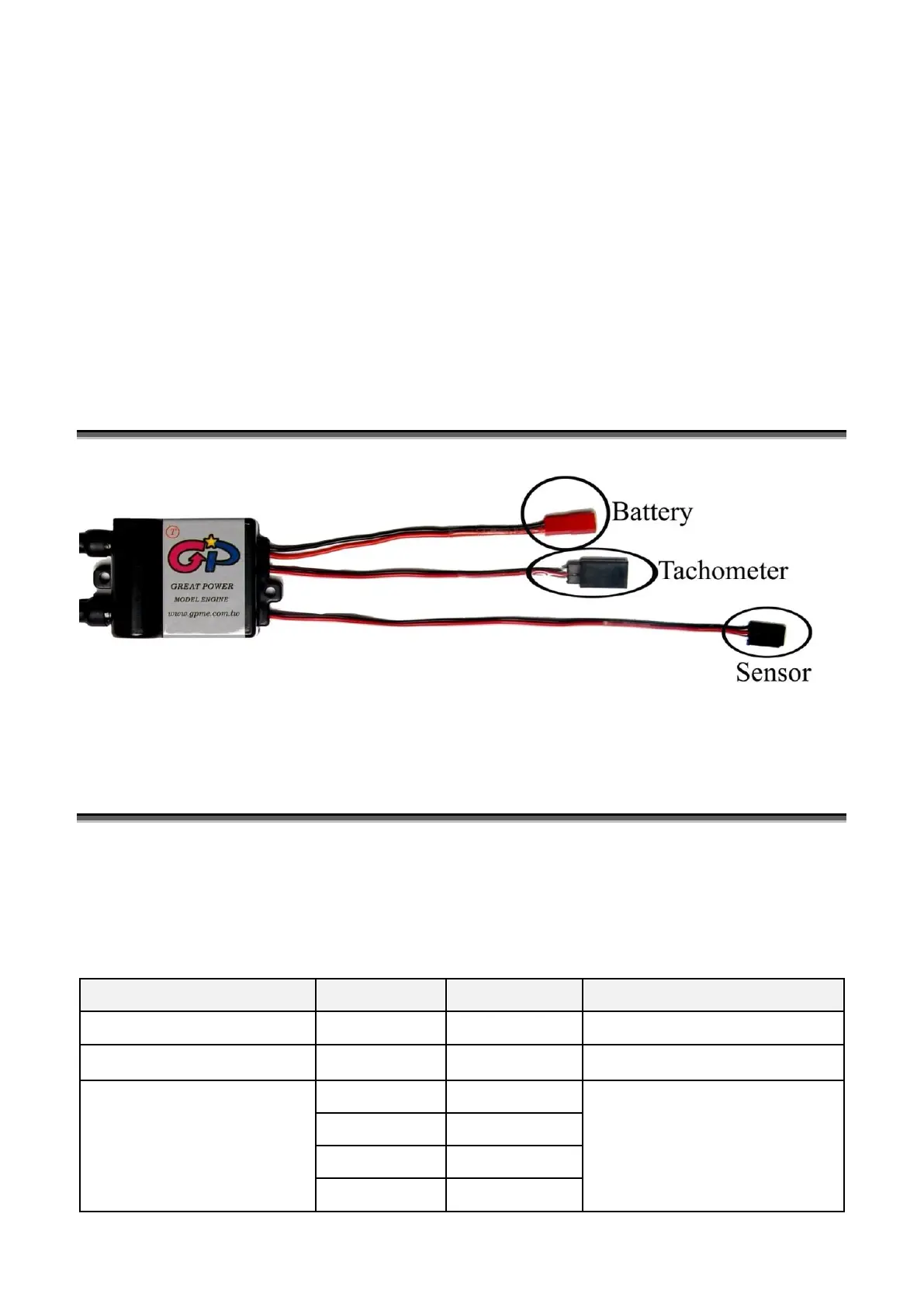

IGNITION WIRE DIAGRAM

Voltage Input: 6.6V~8.4V

WARNING: DO NOT USE TACHOMETER PORT FOR POWER IN

MAINTENANCE

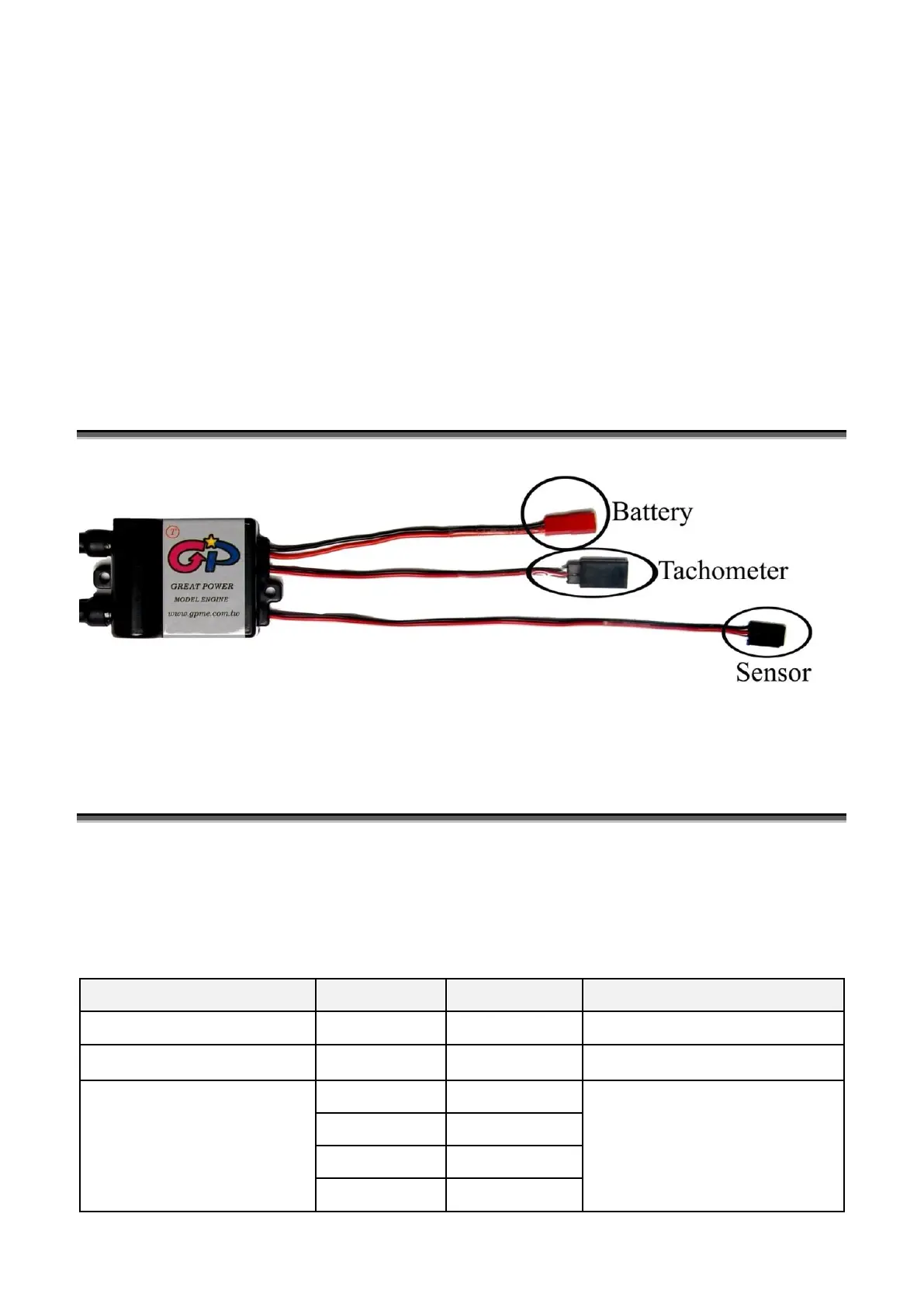

As a high-performance two-stroke engine, certain parts of GP178 may wear out more quickly than the

other models. Pistons, piston rings, needle bearings, spark plugs and so on may need to be occasionally

replaced out of warranty to maintain peak performance. Check screws of the engine, firewall, and

propeller to make sure they are in good condition and well tightened to the required torque value on a

regular basis. The following chart lists the sizes of screws and their torque values.

Loading...

Loading...