GREE GMV5E DC INVERTER VRF UNITS SERVICE MANUAL

270

Precondition: No refrigerant exists in the pipeline system and the power supply has been disconnected.

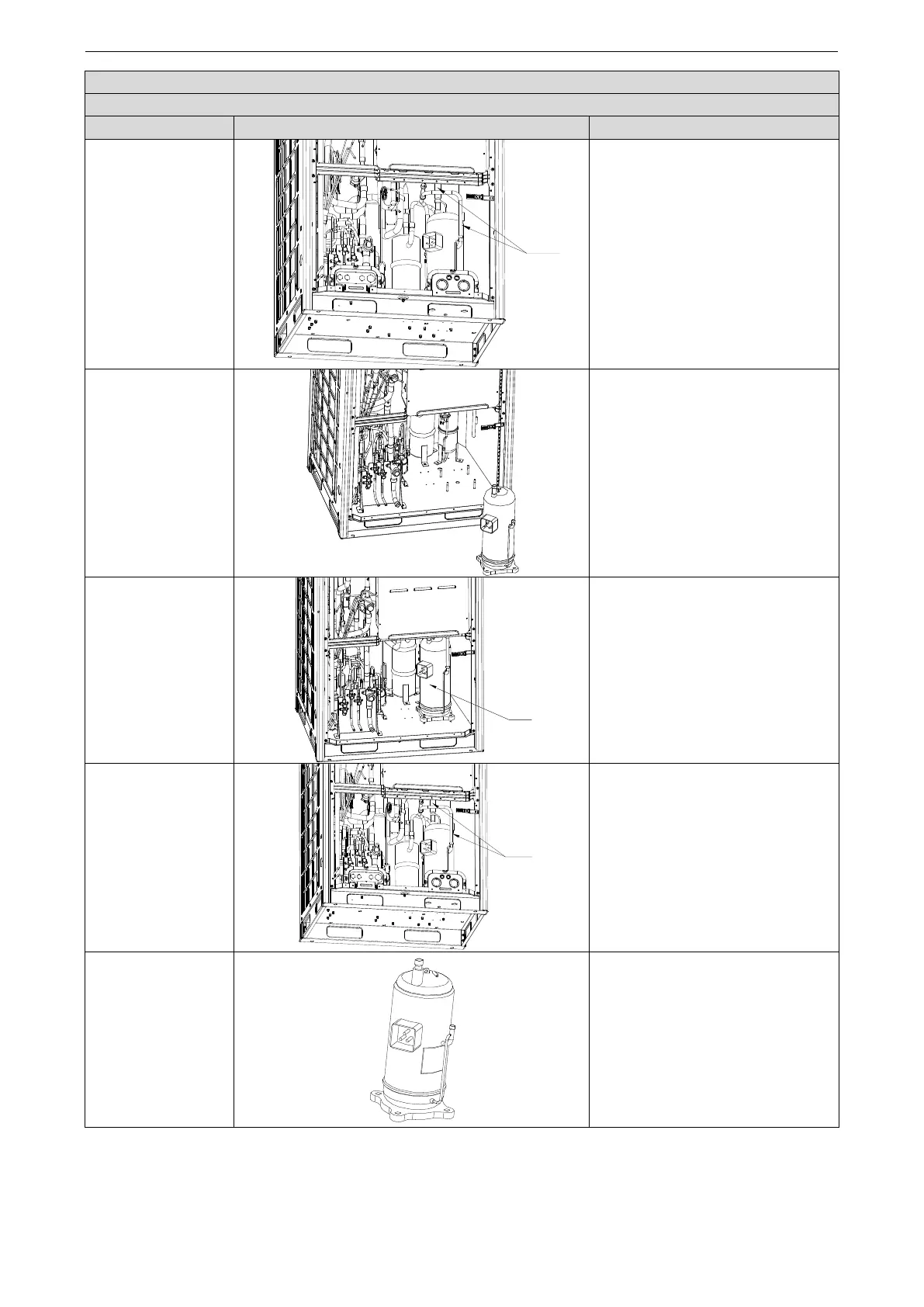

4. Remove the

suction and

discharge pipes.

●Heat the suction and discharge

pipes by acetylene welding and then

remove the pipes.

●During welding, charge nitrogen into

the pipes. The pressure should be

controlled within 0.5±0.1 kgf/cm

2

(relative pressure).

●Avoid nearby materials from being

burnt during welding.

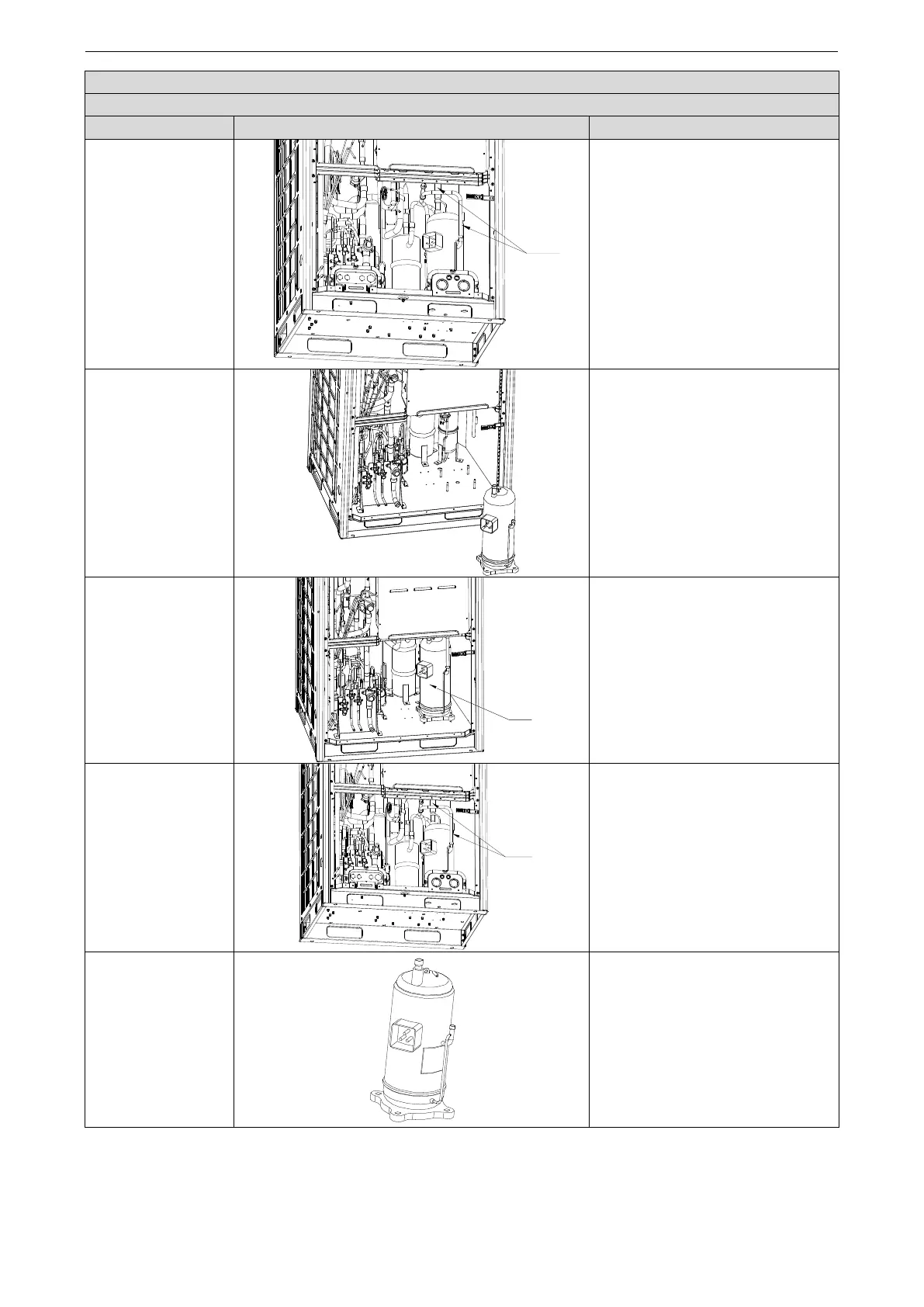

5. Remove the

compressor.

●Remove the compressor from the

chassis.

6. Install a new

compressor on the

chassis.

●Put the compressor in a proper

position.

●Use a wrench to screw the nuts on

the compressor.

●The compressor should not be

installed upside down.

7. Connect the

suction and

discharge pipes of

the compressor to

the pipeline system.

●Heat the suction and discharge

pipes by acetylene welding and then

install the pipes.

●During welding, charge nitrogen into

the pipes. The pressure should be

controlled within 0.5±0.1 kgf/cm

2

(relative pressure).

●Avoid nearby materials from being

burnt during welding.

8. Connect the power

line to the

compressor, and

install the electric

heating belt, top

temperature sensor,

and discharge air

temperature sensor.

●Put the power line in a proper

position.

●Use a screwdriver to screw the

power line.

●Install the electric heating belt, top

temperature sensor, and discharge

air temperature sensor.

●Put the sound-proof sponge back to

position.

Loading...

Loading...