GREE GMV5E DC INVERTER VRF UNITS SERVICE MANUAL

73

Step 8: Perform step 3 again.

Step 9: Perform step 5 and step 6 again. Record the weight before perfusion m3 and weight after

perfusion m4.

Step 10: If there is no sufficient refrigerant and the calculated quantity of refrigerant is not fulfilled for

the system, record the current total perfusion quantity.

m=(m1-m2) +(m3-m4) +…+(mn-1-mn)

Quantity of refrigerant to be perfused during running m`=M-m

M is the required total quantity

If the pre-perfusion quantity (m) reaches the required total quantity for the system, turn off the valve

of the refrigerant tank immediately to finish perfusing and proceed with step 11.

Step 11: Remove the pressure gauge.

9.2.2 Refrigerant Perfusion During Running

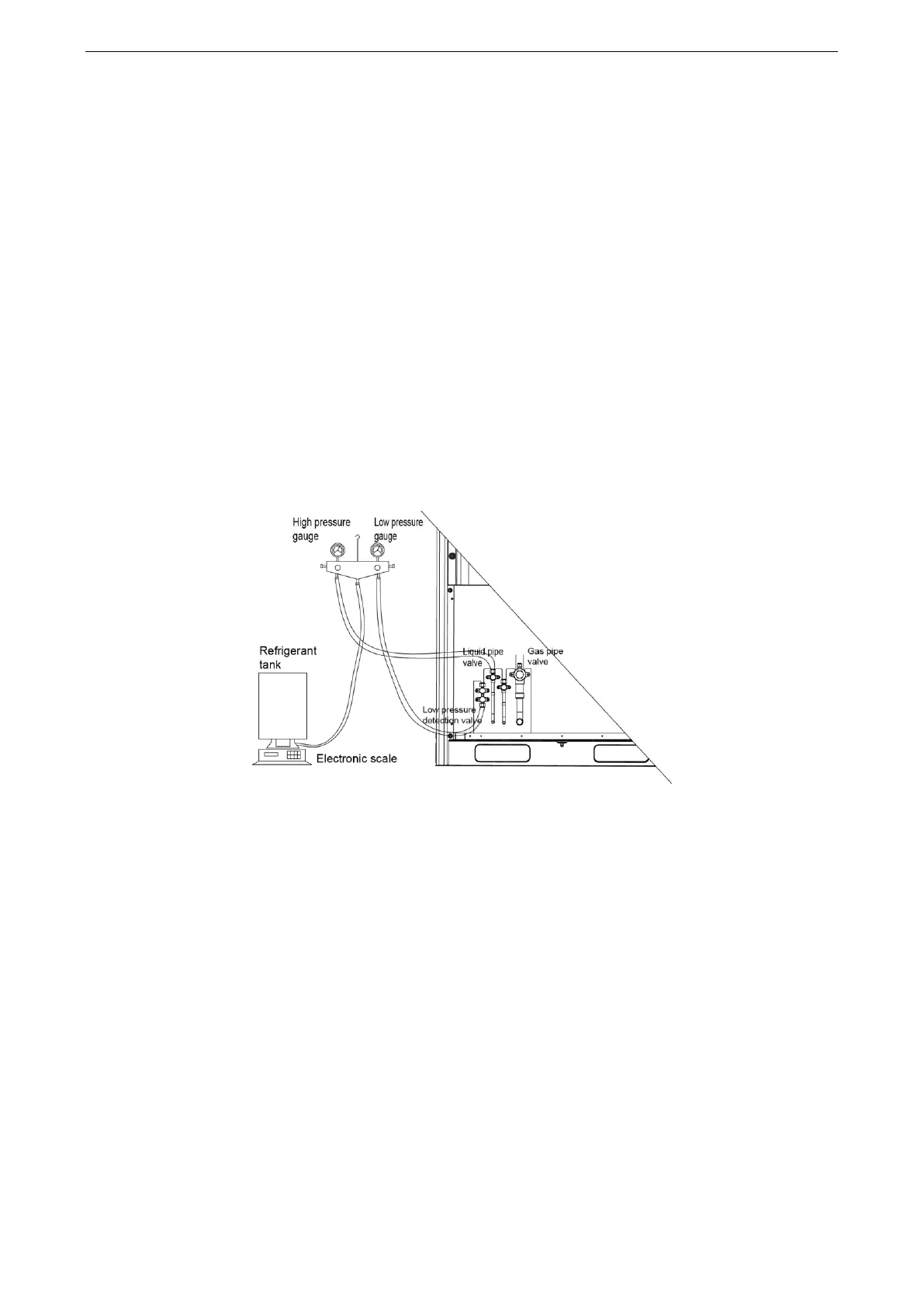

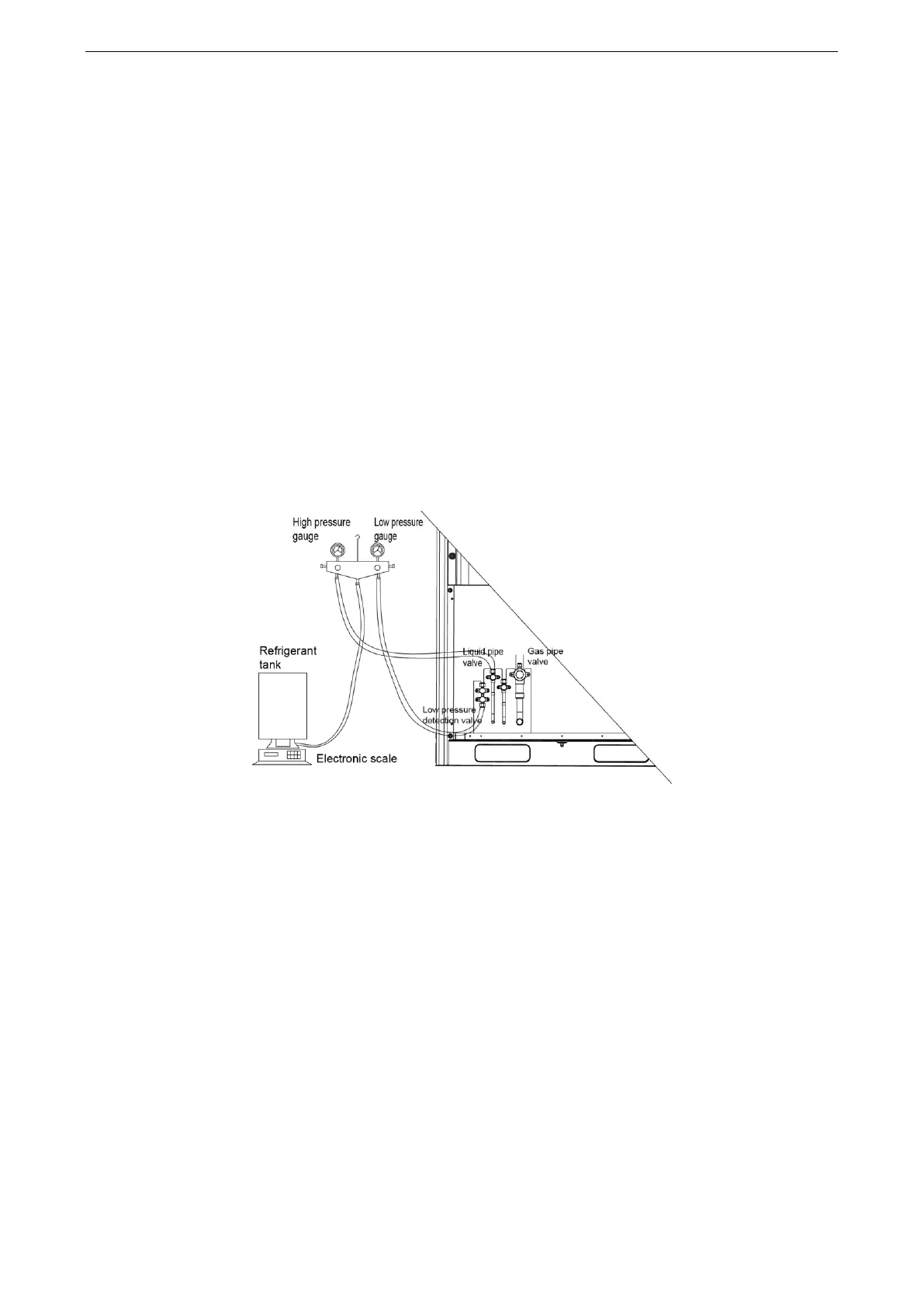

Step 1: Turn off the valve of the refrigerant tank and reconnect the pressure gauge pipe. Disconnect

the low pressure gauge pipe from the detection valve opening of the gas liquid and connect it to the low

pressure detection valve, as shown in the following figure.

Step 2: Turn on the valves for the liquid and gas pipes of each module completely. For the modular

unit, the oil-equalizing valve of each module also needs to be turned on.

Step 3: Make the system to run in commissioning mode via the commissioning software or the main

board of the ODU. (For details, see the description on commissioning.)

Step 4: When the commissioning step goes to refrigerant perfusion, turn on the valve of the

refrigerant tank and perfuse the remaining quantity (m`).

Step 5: After all refrigerant is perfused, turn off valve of the refrigerant tank and wait till

commissioning is automatically is completed for the system.

Step 6: Remove the pressure gauge to finish refrigerant perfusion.

Loading...

Loading...