23

Installation and Maintenance

Service Manual

0DOIXQFWLRQ&KHFNLQJDQG(OLPLQDWLRQ

Compressor overload protection

Viewing malfunction code

through remote controller within

200s; displayed directly on

nixietube after 200s

H3

PLnoitcnuflamerawdraHhctamtonodtinuroodtuodnatinuroodnI

EEnoitcnuflamerawdraHpihcyromemfonoitcnuflaM

Wrong connection of communication wire or malfunction of

electronic expansion valve

Hardware malfunction

dn

3LnoitcnuflamerawdraH1nafroodtuofonoitcetorpnoitcnuflaM

Detection status of wrong connection of communication wire

or malfunction of electronic expansion valve

Operation status

dd

7EsutatsnoitarepOtcilfnocedoM

oFsutatsnoitarepOedomgnilcycertnaregirfeR

LAsutatsnoitarepOnaf-X

1HsutatsnoitarepOedomgnitaehninruterliorognitsorfeD

Start failure of compressor

Viewing malfunction code

through remote controller within

200s; displayed directly on

nixietube after 200s

Lc

4ErosserpmocfonoitcetorperutarepmetegrahcsidhgiH

Overload protection E8

5EnoitcetorptnerrucrevotinuelohW

5PnoitcetorptnerrucesahprosserpmoC

Compressor desynchronizing H7

dLnoitcetorpesrevni-esahp/gnikcal-esahprosserpmoC

IPM modular protection H5

DC bus-bar low volt LPnoitcetorpega

HPnoitcetorpegatlovhgihrab-subCD

PFC protection HC

7Ulamronbasievlavyaw-ruofehT

18K: 24K:

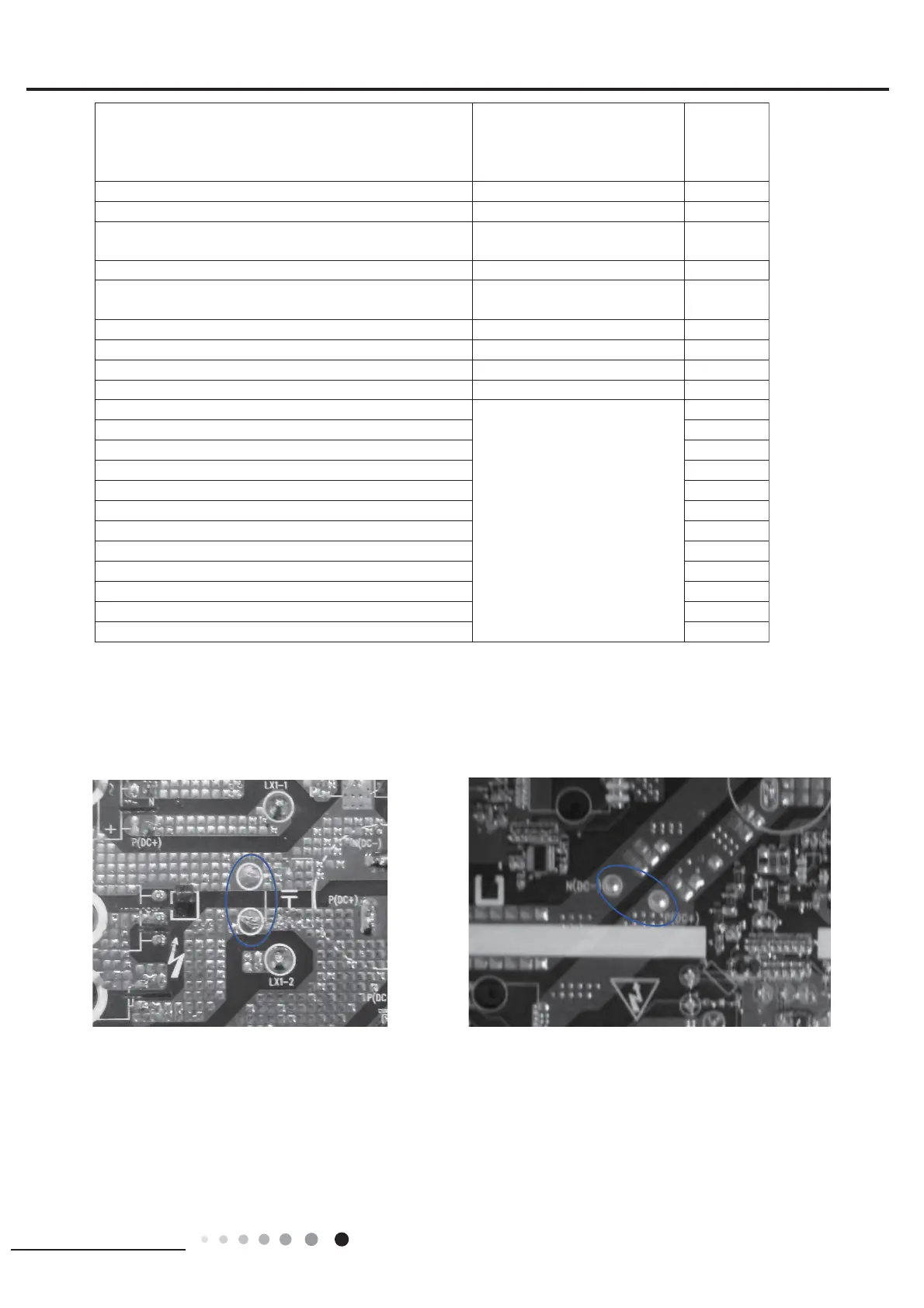

Note: discharge the position in below pictures with discharge resistance after open the top cover and

check if the voltage is belo

w 20V with universal meter, then begin to check.

1 IPM protection malfunction:

Main checking point:

● If the input voltage of the unit is within normal range?

● If the connection wire of compressor is connected well

? Is it loose? If the connection sequence is correct?

● If the resistance of compressor coil is normal? If the isolation of compressor coil with copper pipe is good?

● If the unit is overloaded? If the heat radiation of the unit is good?

●

If the refrigerant charge is suitable?

Flow

chart:

Loading...

Loading...