5

Upblast Centrifugal Roof Exhaust Fans

Grease Trap

A grease trap is an aluminum trap designed to collect

grease residue to avoid drainage onto roof surface. It

contains a built-in water separating baffle.

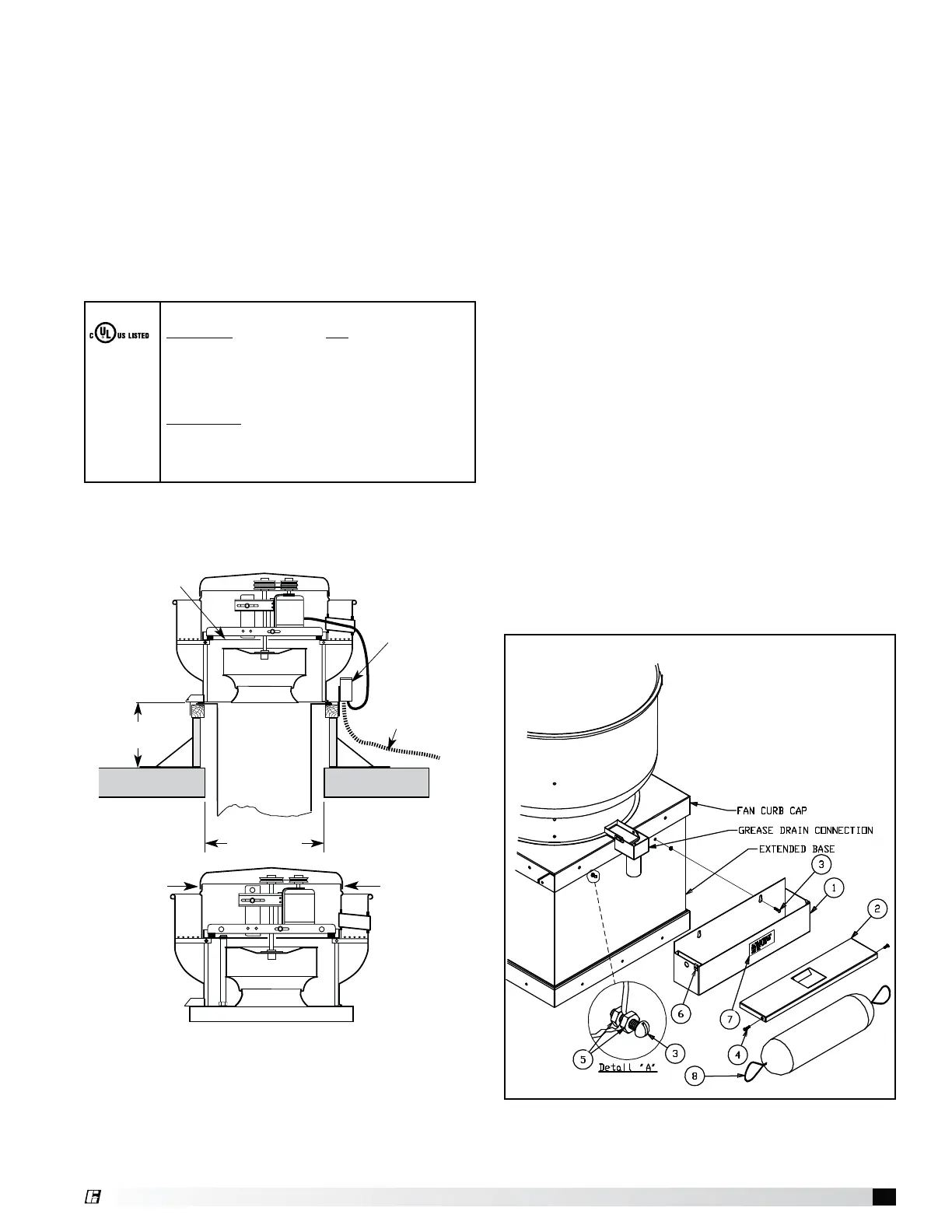

Instructions

1. Apply cover to grease trap. Install clip nuts to trap

over holes provided. Attach cover with two no.

10 - 24 x 1/2 fasteners.

2. Position the container under the grease drain so

the drain spout enters the cover approximately

1-1/2 to 2in. (38 to 51 mm).

3. Locate and mark the container mounting holes on

the extended base or roof curb.

4. Drill 3/16 in. (5 mm) diameter holes in marked

loations.

5. Apply container with no. 10 - 24 x 3/4 fasteners.

See Detail “A” in figure 6. If extended base is vented

type, allow space between screw head and container

for vent projections.

6. For most climates, fill container with water (at

installation and after each cleaning) until it flows out

the drain hole. The unit is now ready for use.

Maintenance

Regular inspection of grease trap is recommended.

Depending on the amount of grease discharged through

the fan, the grease trap should be changed accordingly

to ensure proper operation.

Grease Trap Installation

Parts List

1 - Grease Trap

2 - Grease Trap Cover

3 - No. 10 24 x 3/4 Slot RD HD SS MS

4 - No. 10 24 x 1/2 Slot RD HD SS MS

5 - No. 10 24 Hex SS Nut

6 - No. 10 24 Clip Nut

7 - Instruction Label

8 - Optional Grease Absorber

Fig. 6

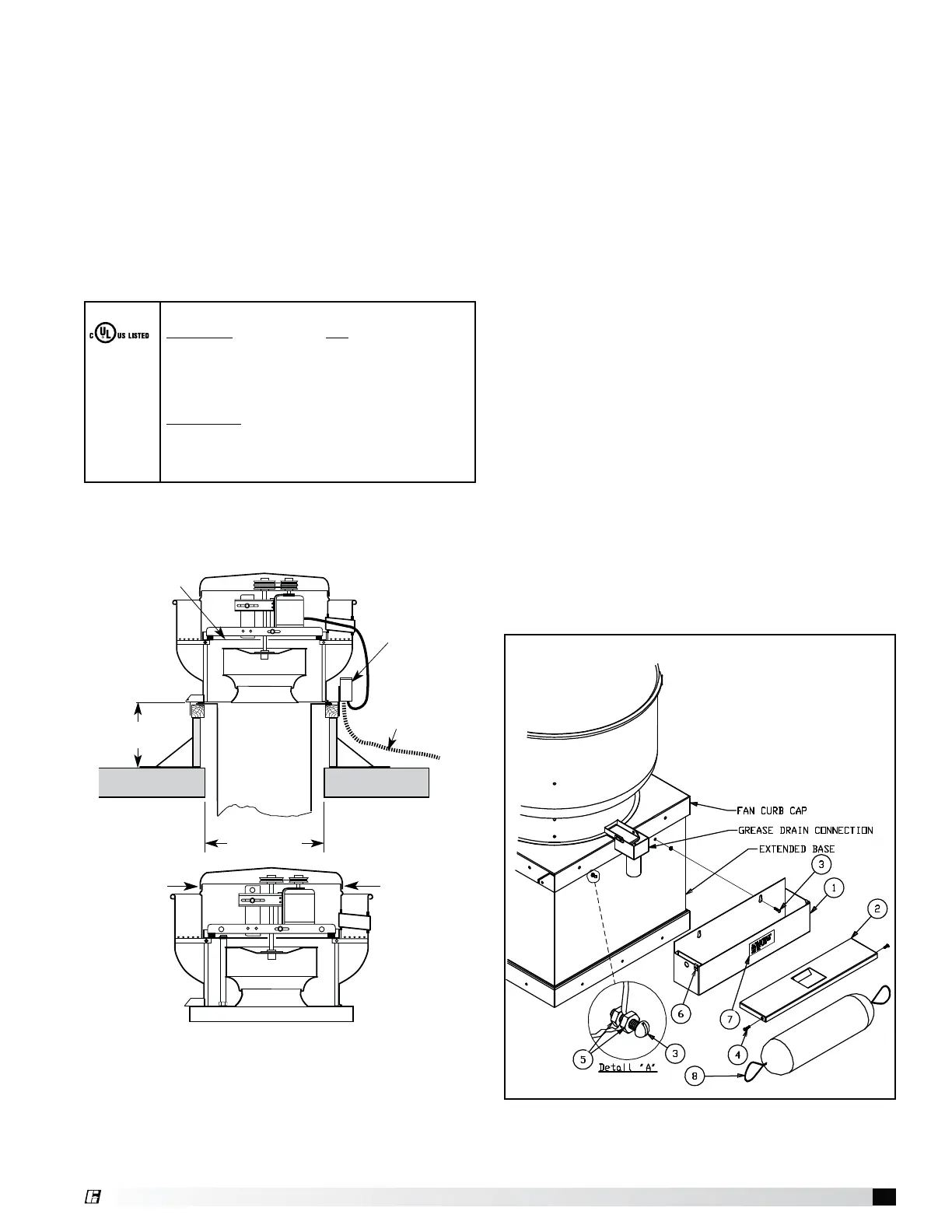

Factory

Installed

Heat Baffle

8 in. (203 mm)

minimum

Recommended

Roof Opening

NEMA-3R

Disconnect

factory wired

from motor to

disconnect

through the

breather tube

Liquid Tight

Flexible Conduit

by Others

Roof Deck

Recommended Emergency Smoke

Control Installation

Electric Connection

Emergency Smoke Control

The motor’s amperage and voltage rating must be

checked for compatibility to the supply voltage prior to

final electrical connection. Also, the motor itself cannot

have thermal overload.

For emergency smoke removal application, the electrical

supply must enter the motor compartment through the

breather tube. Disconnect must be mounted outside the

fans motor compartment. Consult local code authorities

for your specific requirements. Shown below is the UL

Listed label that the fan will bear.

For belt drive units in emergency smoke removal

installations, the electrical supply must be kept out of

the airstream. They may also require an isolated power

supply so that if power is cut to the building in the event

of a fire, the fan will continue to operate. Check the

local and national electrical codes for emergency smoke

removal fans.

Listed

Power

Ventilator

For

Smoke

Contol

Systems

76Y9

-- IMPORTANT --

ELECTRICAL -- If fan motor is NOT thermally protected,

remote overload protection must be installed having

adequate rating as to voltage, frequency, horsepower,

and full load current per phase. Where connected to a

circuit protected by fuses, use time delay fuses. For supply

connection, use wires rated for at least 90

°

C (194°F).

INSTALLATION -- When connecting electrical power

to this fan, do not restrict motor movement. Motor must

have sufficient movement for possible future belt or wheel

adjustment.

454975

Screw

Screw

®

Loading...

Loading...