Model IG / IGX Make-Up Air 3

®

Indirect Gas-Fired Unit Installations

Units are listed for installation in the United States and

Canada.

• Installation of gas-fired duct furnaces must conform

with local building codes. In the absence of local

codes, installation must conform to the National

Fuel Gas code, ANSI Z223.1 or in Canada, CAN/

CGA-B149 installation codes.

• All electrical wiring must be in accordance with the

regulation of the National Electrical Code, ANSI/

NFPA 70.

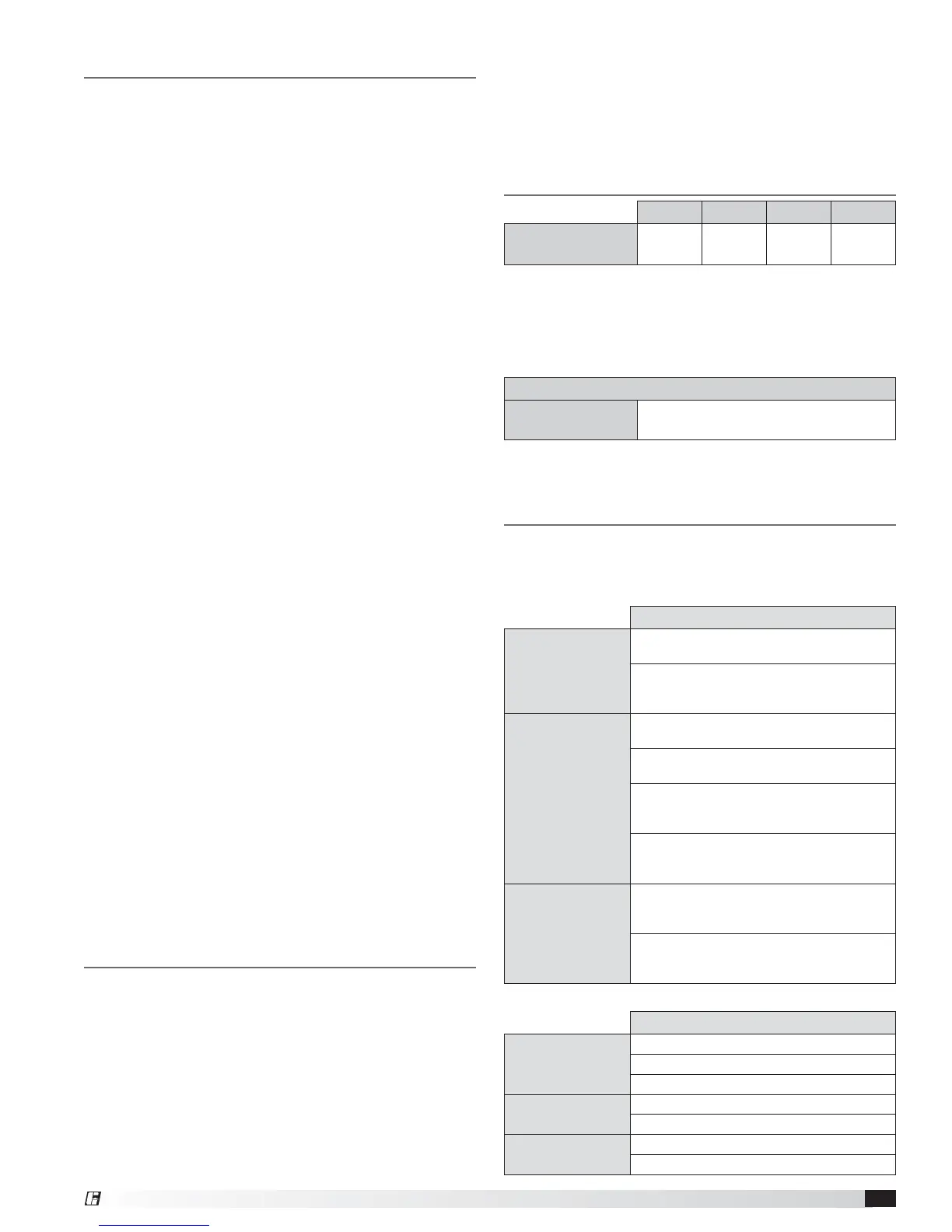

Clearance to Combustibles /

Service Clearances

Floor Top Sides Ends

Indirect Fired

Units*

0 inches

(0 mm)

0 inches

(0 mm)

0 inches

(0 mm)

0 inches

(0 mm)

Clearance to combustibles is defined as the minimum

distance required between the heater and adjacent

combustible surfaces to ensure the adjacent surface’s

temperature does not exceed 90° above the ambient

temperature.

*Reference venting guidelines for combustion blower clearances.

Recommended Minimum Service Clearances

Housing 32

and less

42 inches

(1067 mm)

on the

controls side of the unit

Clearances for component removal (such as evaporative

cooler media) should be 6 in. wider than the width of the

module itself.

Table of Contents

Installation

Indirect Gas-Fired Unit Installations .............3

Clearance to Combustibles/Service Clearances ....3

Additional IOMs for Reference ..................3

Indoor Unit .................................4

Unit Arrangement DB / HZ ................... 4-5

Roof Mounted Unit – Arrangement DBC ........ 5-6

Optional Evaporative Cooling Module ............7

Installation of Furnace Connections .............7

Electrical Wiring ........................... 7-8

Optional Evaporative Cooler Piping ........... 9-10

Optional Direct Expansion (DX) Coil Piping .... 10-11

Optional Chilled Water Coil Piping .............12

Optional Building Pressure Control .............12

Optional Dirty Filter Switch ...................13

Start-Up

Blower ................................ 13-14

Optional Economizer ..................... 15-16

Optional Evaporative Cooling .................17

Operation

Optional VAV Units ..........................18

Optional Recirculating Units ..................19

Sequence of Operation ......................20

Troubleshooting

Blower ...................................21

Motor Over Amps. . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Insufficient / Too Much Airflow ................23

Excessive Noise / Vibration ...................24

Furnace ..................................24

Optional Evaporative Cooling .................25

Maintenance

Routine ................................ 26-27

Fall ................................... 28-29

Reference

Vent Connections ...........................30

Model IG – Single or 2 Stage ..................31

8:1 Staged ..............................32

4:1 Modulation ...........................33

Model IGX – Blower Control Center ............34

Start-Up Checklist ..........................35

Maintenance Log ................. Backcover

Our Commitment ................. Backcover

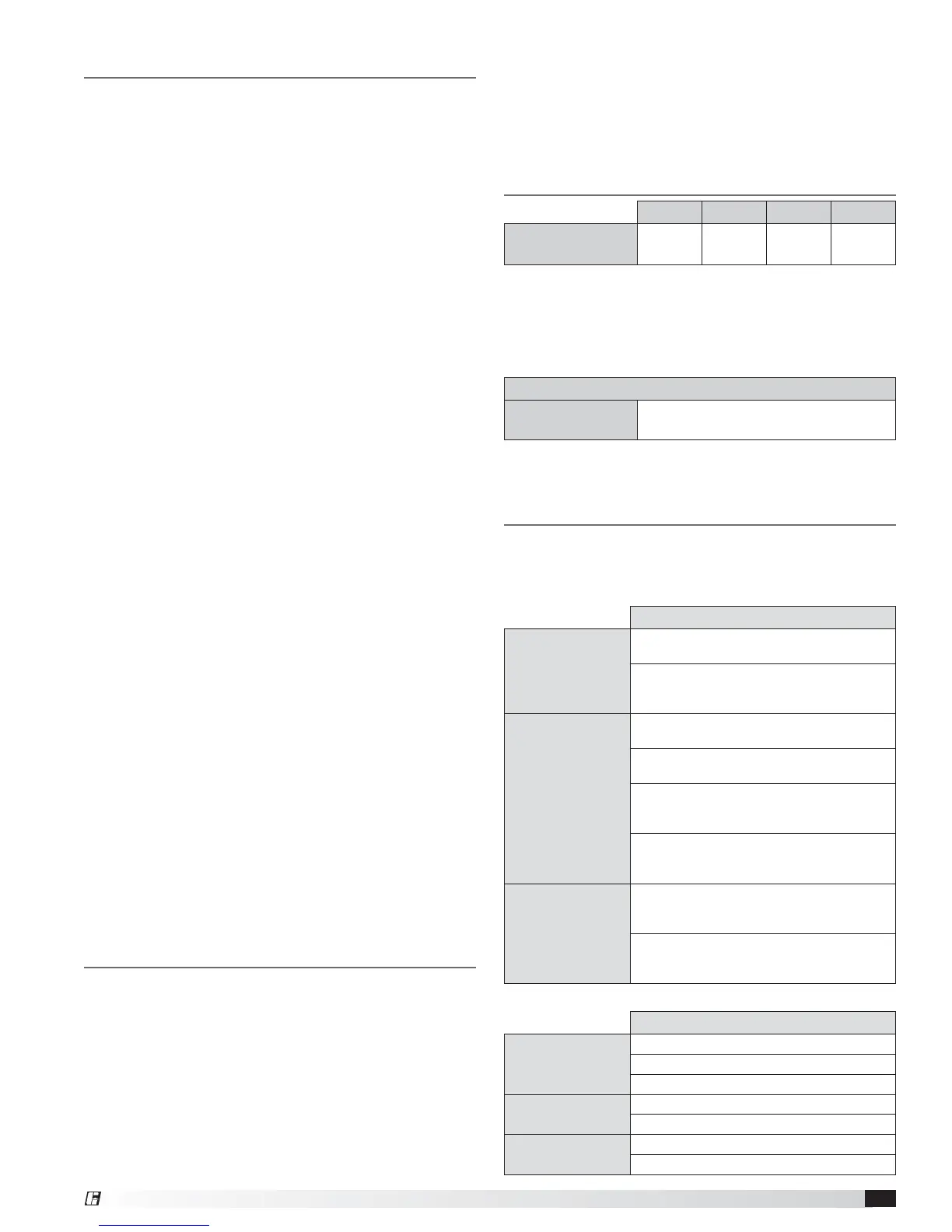

Additional IOMs for Reference

For complete furnace information reference the Indirect

Gas-Fired Heat Modules Installation, Operation and

Maintenance Manual. Available turndown control

options include:

Electronic Modulation

Single Furnace

Unit

4:1- uses modulating valve and furnace

controller

*High turndown uses a 4:1 modulating

valve with a proprietary manifold and

furnace controller

Two Furnace

Unit

8:1- uses one 4:1 modulating furnace with

furnace controller and one 2-stage furnace

4:1 - uses two 4:1 modulating furnaces

controlled in parallel

*High turndown furnaces in a series

configuration use one high turndown

furnace and one 2-stage furnace

*High turndown furnaces in a parallel

configuration use two high turndown

furnaces, controlled in parallel

Three Furnace

Unit

12:1 - uses one 4:1 modulating furnace,

one 2 stage furnace and one 1-stage

furnace

*High turndown uses one high turndown

furnace, one 2-stage furnace, and one

1-stage furnace

* High turndown furnace patent pending.

Staged

Single Furnace

Unit

8 stage

2 stage

1 stage

Two Furnace

Unit

4-stage uses two 2-stage furnaces

2-stage uses two single-stage furnaces

Three Furnace

Unit

6-stage uses three 2-stage furnaces

3-stage uses three 1-stage furnaces

• Unit is approved for installation downstream from

refrigeration units. In these conditions, condensate

could form in the duct furnace and provision must be

made to dispose of the condensate.

Loading...

Loading...