Model IG / IGX Make-Up Air10

®

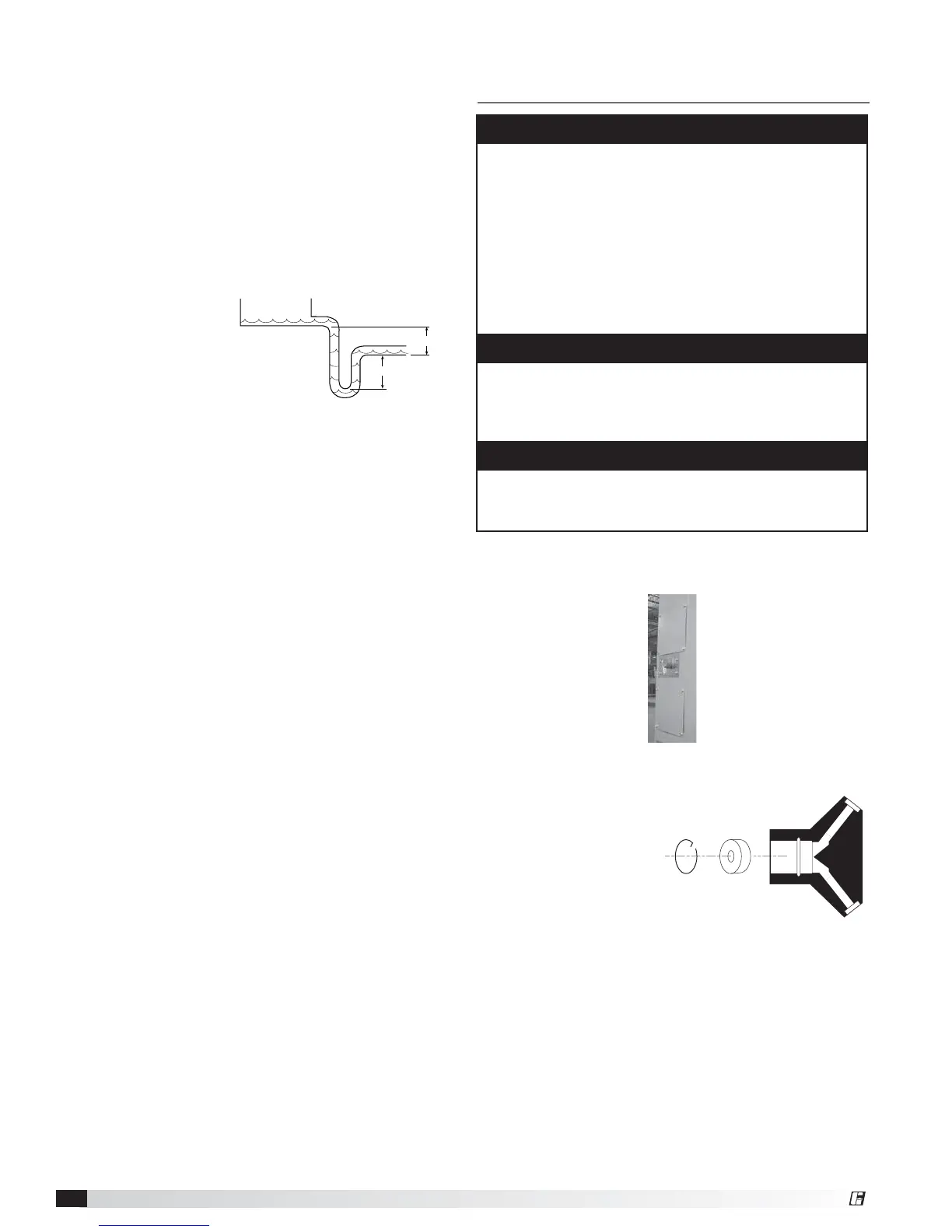

6 in. min.

6 in. min.

Drain

Trap

1. Install the Water Supply Line

Supply line opening requirements vary by unit size

and arrangement and are field-supplied. Connect the

water supply line to the float valve through the supply

line opening in the evaporative cooling unit. Install the

1/2inch normally closed solenoid (Valve A) in the supply

line. Install the 1/4 inch normally open solenoid (Valve B)

between the supply line and the drain line as shown.

2. Install the Drain Line

Connect an unobstructed drain line to the sump drain

overflow connection. Install the 3/4 in. normally open

solenoid (Valve C) between the sump drain connection

and the drain line. A

trap must be used to

overcome the internal

negative pressure in the

unit and allow the water

to drain while the unit is

operating.

3. Check/Adjust Water Level

Check the water level in the sump tank. The water

level should be above the pump intake and below the

overflow. Adjust the float as needed to achieve the

proper water level.

Installation - Direct Expansion (DX)

Coil Piping (optional)

1. Locate the Distributor(s) by Removing

the Distributor Access Panel

Distributor Access Panel

IMPORTANT

Guidelines for the installation of direct expansion

cooling coils have been provided to ensure proper

performance and longevity of the coils. These are

general guidelines that may have to be tailored

to meet the specific requirements of any one job.

As always, a qualified party or individual should

perform the installation and maintenance of any coil.

Protective equipment such as safety glasses, steel

toe boots and gloves are recommended during the

installation and maintenance of the coil.

IMPORTANT

All field-brazing and welding should be performed

using high quality materials and an inert gas purge

(such as nitrogen) to reduce oxidation of the internal

surface of the coil.

IMPORTANT

All field-piping must be self-supporting and flexible

enough to allow for the thermal expansion and

contraction of the coil.

2. Verify Nozzle Placement

Inspect the refrigerant

distributor and verify

that the nozzle is in

place. The nozzle is

generally held in place

by a retaining ring or is

an integral part of

the distributor itself.

Retainer

Ring

Nozzle Distributor

Nozzle Placement

Loading...

Loading...