Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

1

®

Part #470658

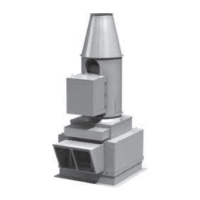

MSX

Make-Up Air Unit

®

®

Model MSX Make-Up Air

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if high winds

or seismic activity are present. If more information

is needed, contact a licensed professional engineer

before moving forward.

1. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electric Code (CEC) in

Canada.

General Safety Information

IMPORTANT

All factory provided lifting lugs must be used when

lifting any unit. Failure to comply with this safety

precaution could result in property damage, serious

injury or death.

WARNING

Disconnect all electrical power to the fan and secure

to the “OFF” position prior to inspection or servicing.

Failure to comply with this safety precaution could

result in serious injury or death.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage,

injury or death. Read the installation, operating

and maintenance instructions thoroughly before

installing or servicing this equipment.

2. The rotation of the wheel is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan wheel faster than maximum

cataloged fan rpm. Adjustments to fan speed

significantly effects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces, or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open blower access doors while the fan is

running.

DANGER

Always disconnect power before working on or

near a unit. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

CAUTION

When servicing the unit, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.