Replace the chain if:

• The length of the cutting edges is less than 5 mm.

• There is too much space between the drive links

and the rivets.

• The cut speed is slow

• Sharpening the chain many times but it does not

increase the cutting speed. The chain is worn.

5.4 GUIDE BAR MAINTENANCE

Figure 19-20.

NOTE

Make sure that it is turned over periodically to keep

symmetrical wear on the bar.

1. Lubricate the bearings on the nose sprocket (if

present) with the syringe (not included).

2. Clean the bar groove with the scraping hook (not

included).

3. Clean the lubrication holes.

4. Remove burr from the edges and level the cutters

with a flat file.

Replace the bar if:

• the groove is not fit with the height of the drive links

(which must never touch the bottom).

• the inside of the guide bar is worn and make the

chain lean to one side.

6 TRANSPORTATION AND

STORAGE

Before you move the machine, always

• Remove the battery pack from the machine.

• Keep hands clear of the lock-out button.

• Put the scabbard on the guide bar and the chain.

Before you put the machine into storage, always

• Remove all residual oil from the machine.

• Remove the battery pack from the machine.

• Clean all unwanted material from the machine.

• Make sure that the storage area is

• Not available to children.

• Away from agents which can cause corrosion,

such as garden chemicals and de-icing salts.

7 TROUBLESHOOTING

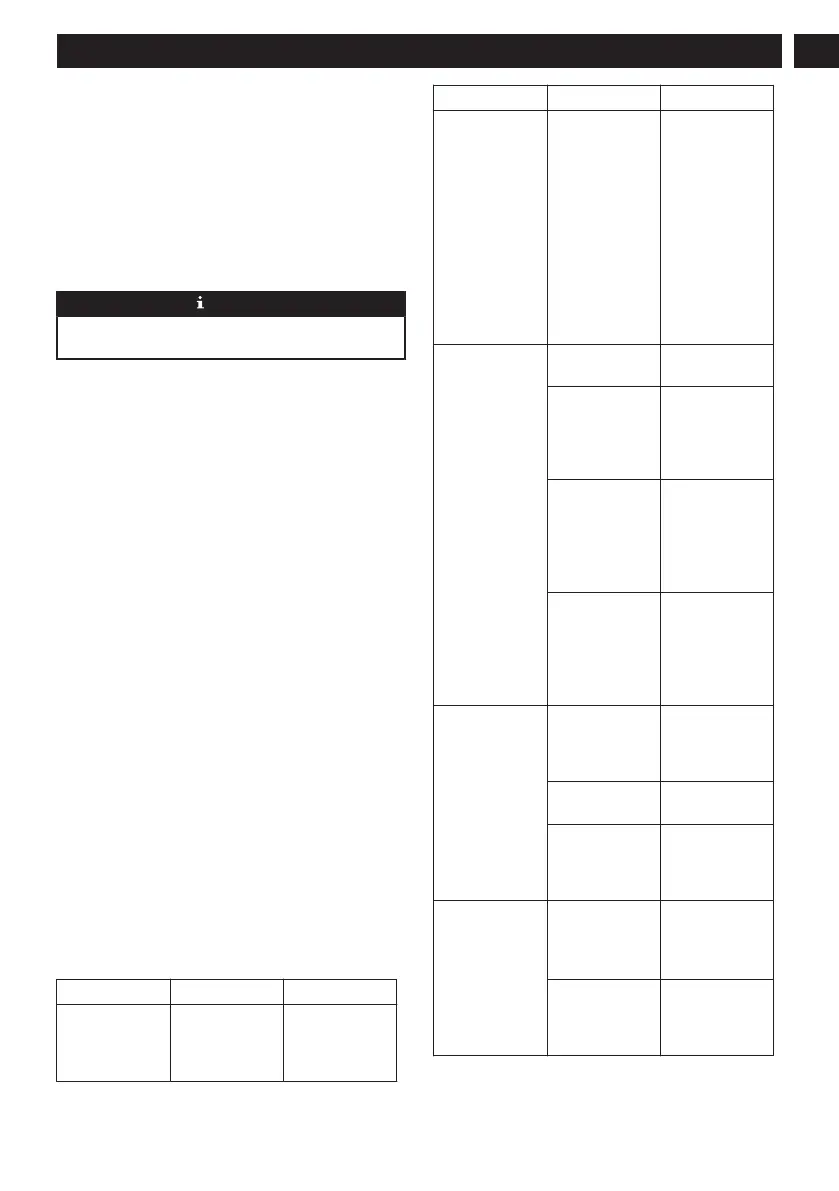

Problem Possible cause Solution

The machine

does not start

The poles are

not assembled

correctly.

Assemble the

poles according

to the instruc-

tions.

Problem Possible cause Solution

The lock-out

button and trig-

ger are not de-

pressed at the

same time.

1. Push and

hold the

lock-out but-

ton

2. While you

hold the

lock-out but-

ton, pull the

trigger.

3. Release the

lock-out but-

ton to start

the machine.

The bar and

chain gets hot

and smokes.

Oil tank is emp-

ty.

Fill the oil tank.

The discharge

port is blocked.

Refer to the

manual to re-

move the bar

and clean out

the debris.

Inlet opening of

inner oil tank is

blocked.

1. Clean the oil

tank.

2. Fill with

clean bar

and chain lu-

bricant.

The sprocket is

stuck and clog-

ged with debris.

1. Clean the

sprocket.

2. Fill with

clean bar

and chain lu-

bricant.

The bar and

chain gets too

hot and can not

cut.

The chain ten-

sion is too tight

or too loose.

Refer to Adjust

the Chain Ten-

sion in the man-

ual.

The chain is dull

Sharpen or re-

place the chain.

The chain is put

on backwards.

Refer to Re-

place the Bar

and Chain in this

manual.

The motor runs,

but the chain

does not cut cor-

rectly, or the mo-

tor stops after

around 3 sec-

onds.

When you use

the machine un-

der load, it

stops.

1. Release the

trigger.

2. Start the ma-

chine again.

The chain is not

lubricated.

Lubricate the

chain to de-

crease the fric-

tion.

7

English

EN

Loading...

Loading...