Operation manual SP 9 - Compact

CHAPTER III – DESCRIPTION OF PLOUGH – Page 11

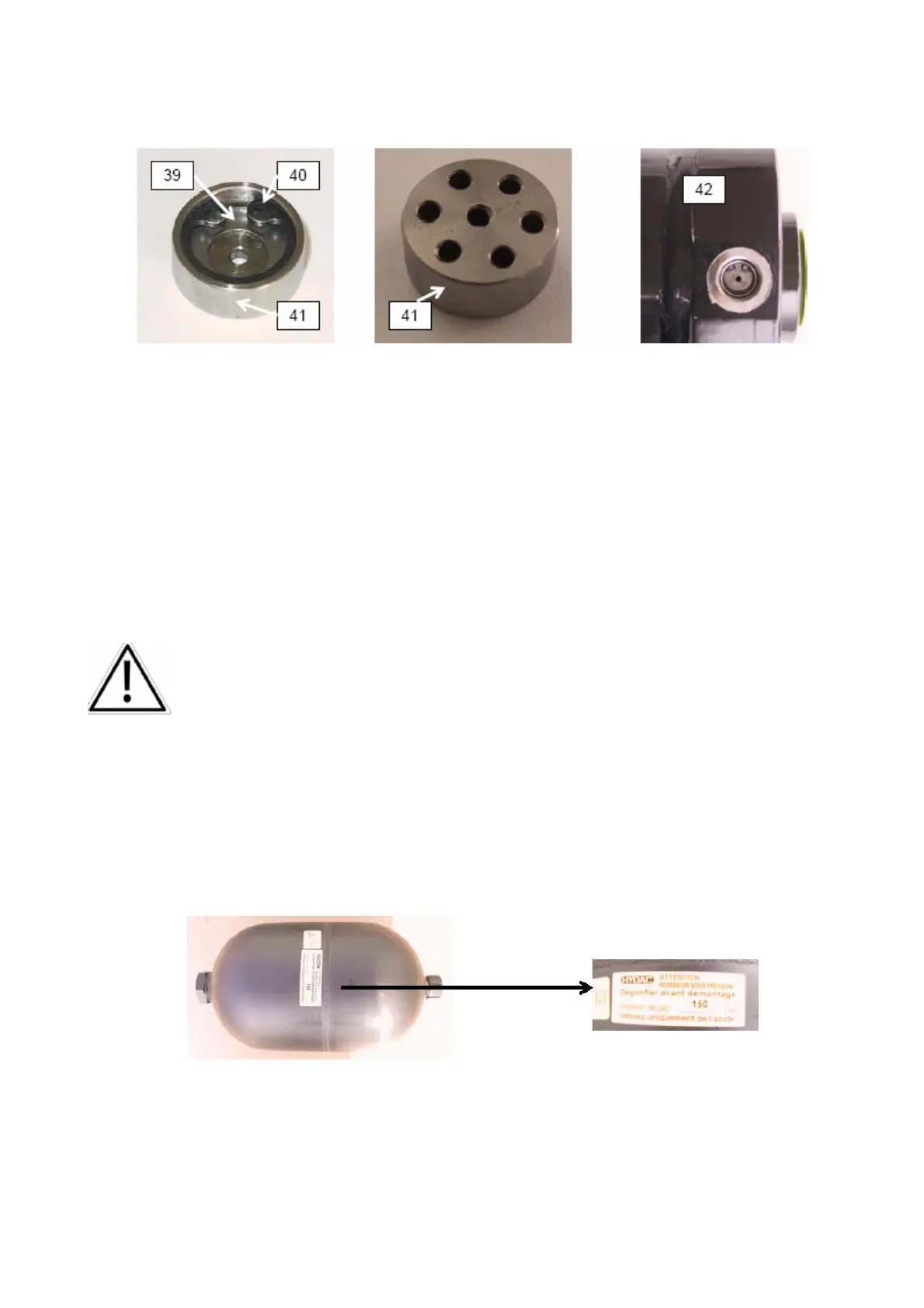

The principle of the work flow limiting pulley :

Inside the pulley (41) there is a plane spring-washer (39) which fastens circlips (40).

When the plough bottom disengages, the oil flowing from the cylinder int he whole length catche

s

the spring-washer circlip. The spring-wacher provides the oil flowing across sevel holes in the

pulley.

After the overcoming the obstacle hydraulic system pressure constrains the oil into the se

curity

cylinder (42)

. The oil going back into the cylinder presses down the spring-washer ont he bottom

of the pulley. Only the middle hole let the oil flow back with the help of it its flowing be

comes slow.

IMPORTANT: Pay attention on the d

irection during the mounting of the pulley (41) into the cylinder

(42). The circlip must look outside.

ATTENTION : The pressure must be decreased

to 0 bar before starting any interference.

Follow the security instructions (chapters «General security instructions» and «Greasing

and maintenance») If it is necessary ask the help from the GRÉGOIRE-BESSON dealer.

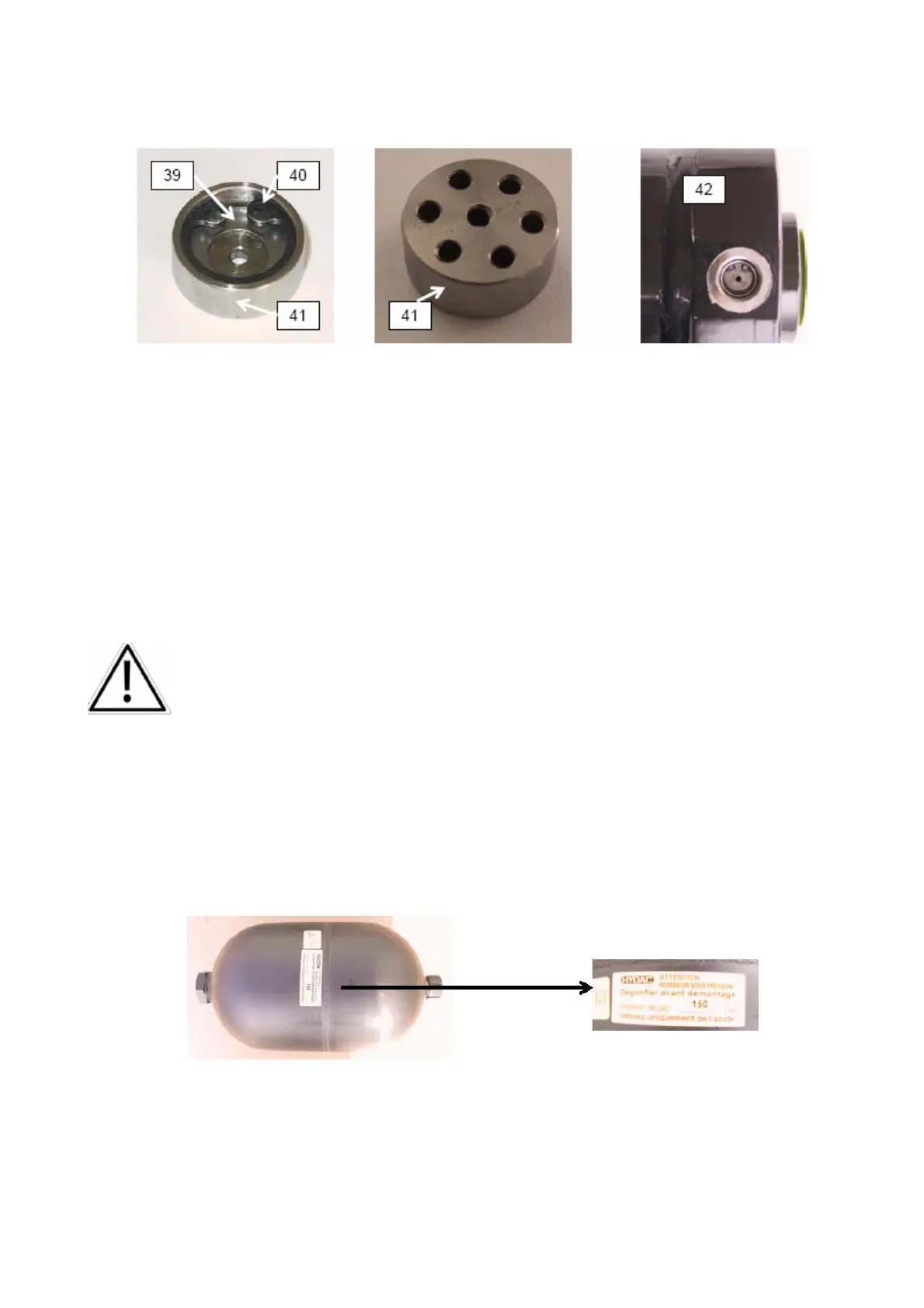

3.9.3 Accumulators

The mounted standard accumulators are used with industrial 100 bar pressure adjustment. The

plough optionally can be mounted with 150 bar accumulators.

Externally th

ere is no difference between two accumulators, the nitrogen adjustment can be seen

ont he label or it is chiseled on the accumulator.

Loading...

Loading...