Do you have a question about the Grohe QUICKFIX and is the answer not in the manual?

Specifies required water pressure range (0.5-10 bar) and maximum safe temperatures (70°C, 60°C).

Recommends a minimum installation height of 1700mm and references DIN and EN standards.

Details connecting the G1/2 thread with a 22mm wrench and other specified dimensions.

Depicts the assembly of shower rail components and other fixtures.

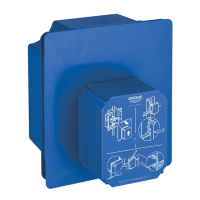

Shows mounting the unit using screws and a 30mm wrench, with reference to specific icons.

Guides on removing an old part and fitting the new unit, with disposal instructions.

Shows how to attach the shower head holder and secure the shower rod.

Guides on attaching the aerator, pipe, and shower head to the system.

Shows height adjustment, decorative cover installation, and control lever adjustment.

Covers using tape, marking, and drilling Ø6mm holes for secure mounting.

Illustrates using screws and assembling various components for final installation.

Shows connecting the main unit and finalizing the shower system assembly.

Shows alignment, shower hose connection, and initial temperature setting.

Illustrates setting the desired water temperature using a thermometer.

Explains how to set the 38°C safety stop for preventing scalding.

Covers the installation of the 43°C temperature limiter for enhanced safety.

Details steps E1-E3 for removing a part, adjusting a cartridge, and setting 38°C.

Covers reassembly and final checks for the 38°C temperature adjustment.

Details steps F1-F3 for removing a part, adjusting a cartridge, and installing the 43°C limiter.

Covers reassembly and final checks for the 43°C temperature limiter adjustment.

Emphasizes reading the guide, following safety measures, and manufacturer liability.

Explains use with different heaters, factory settings, and temperature deviations.

Lists safety stop at 38°C, hot water temp requirements, min. flow rate, and pressure limits.

Advises on draining the system and removing the mixer to prevent frost damage.

Stresses compliance with regulations and turning off the main shut-off valve before work.

Recommends expert help for connectors, avoiding overtightening, and drilling into joints.

Covers setting temperature limits and performing periodic leak checks.

Addresses reversed connections requiring cartridge replacement and checks before drilling.

| Brand | Grohe |

|---|---|

| Model | QUICKFIX |

| Category | Plumbing Product |

| Language | English |