English (GB)

24

9.3.1 Checking input and outputs

Pt100/1000

Use a 100 Ω resistance and decide on the basis on the motor

settings which value this resistance will show in the display when

connected to the terminals instead of the Pt100/1000 sensor.

Analog input, AI

It is possible to measure on the analog input to determine if its

function is correct.

During current state, a 292 Ω resistance in the input converts a

current signal (e.g. 0-20 mA) from the sensor to a voltage signal

for the processor.

Measure the voltage across the input and read the current in the

circuit by means of Grundfos GO Remote or PC Tool. The current

value must be equal to voltage divided with resistance.

Alternatively, a milliammeter can be connected in series with the

circuit.

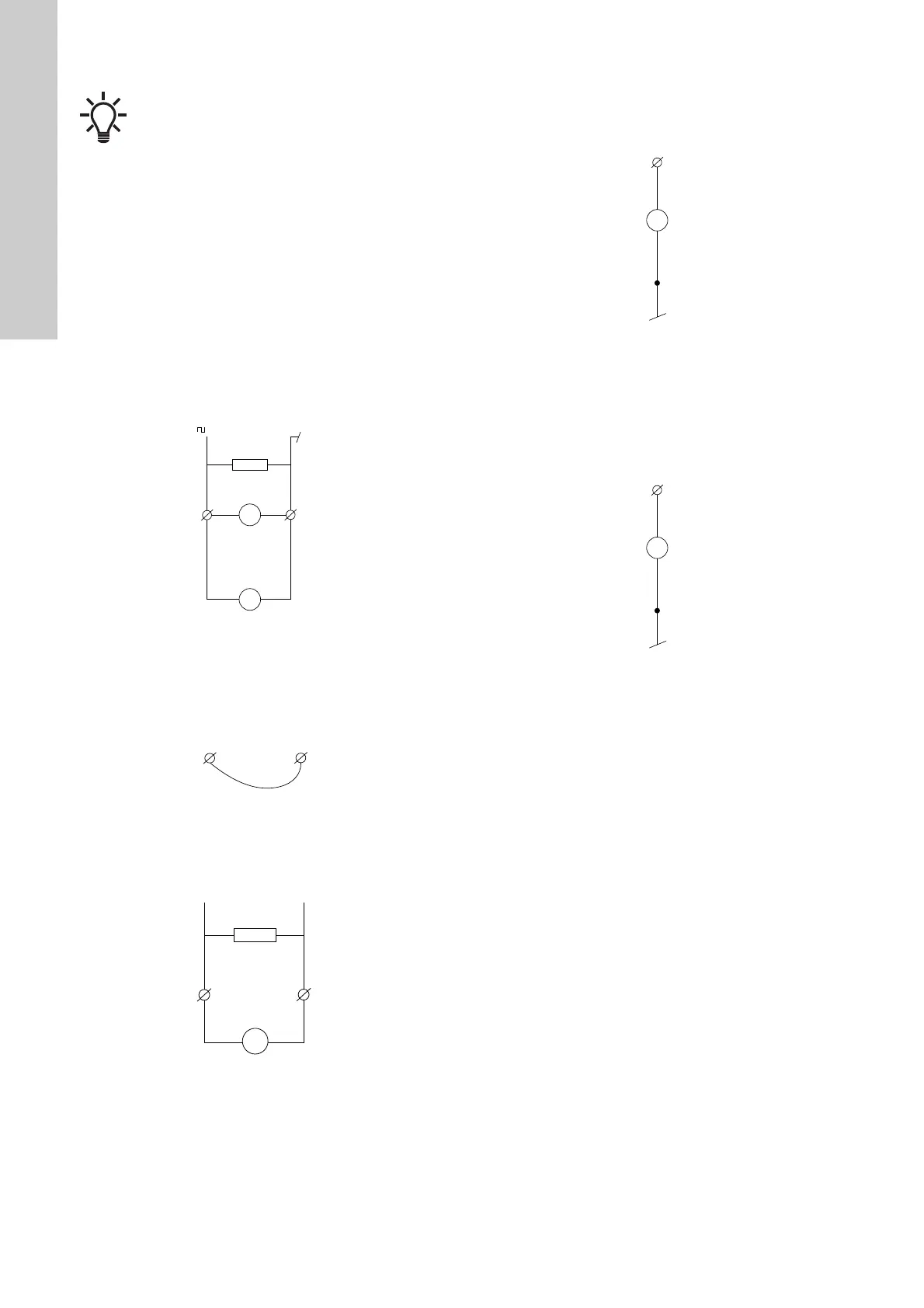

Fig. 55 Measuring on analog input

Next step is to test the input in voltage state. Change the setup of

the input to voltage state (0-10 V). Fit a jumper between terminal

5 (+5 V) and the analog input. 5 V must now be read be means of

PC Tool.

Fig. 56 Testing the input during voltage state

Change the setup of the input to current state and measure on

the input using an ohmmeter. The resistance must be 292 Ω. In

voltage state, the resistance is 122 kΩ.

Fig. 57 Measuring resistance in current and voltage state

Analog output, AO

The analog input is protected against short circuit and will shut

down the signal in case of short circuit. If you suspect a short

circuit, remove the load and compare the value read via PC Tool

with the value measured by means of the measuring instrument.

If the values are not identical, the module is defective.

Digital input, DI

See the settings of the input in PC Tool.

Connect the digital input to frame (GND) by means of an

ammeter. The value measured must now be approximately 12

mA. Check that PC Tool shows a corresponding value.

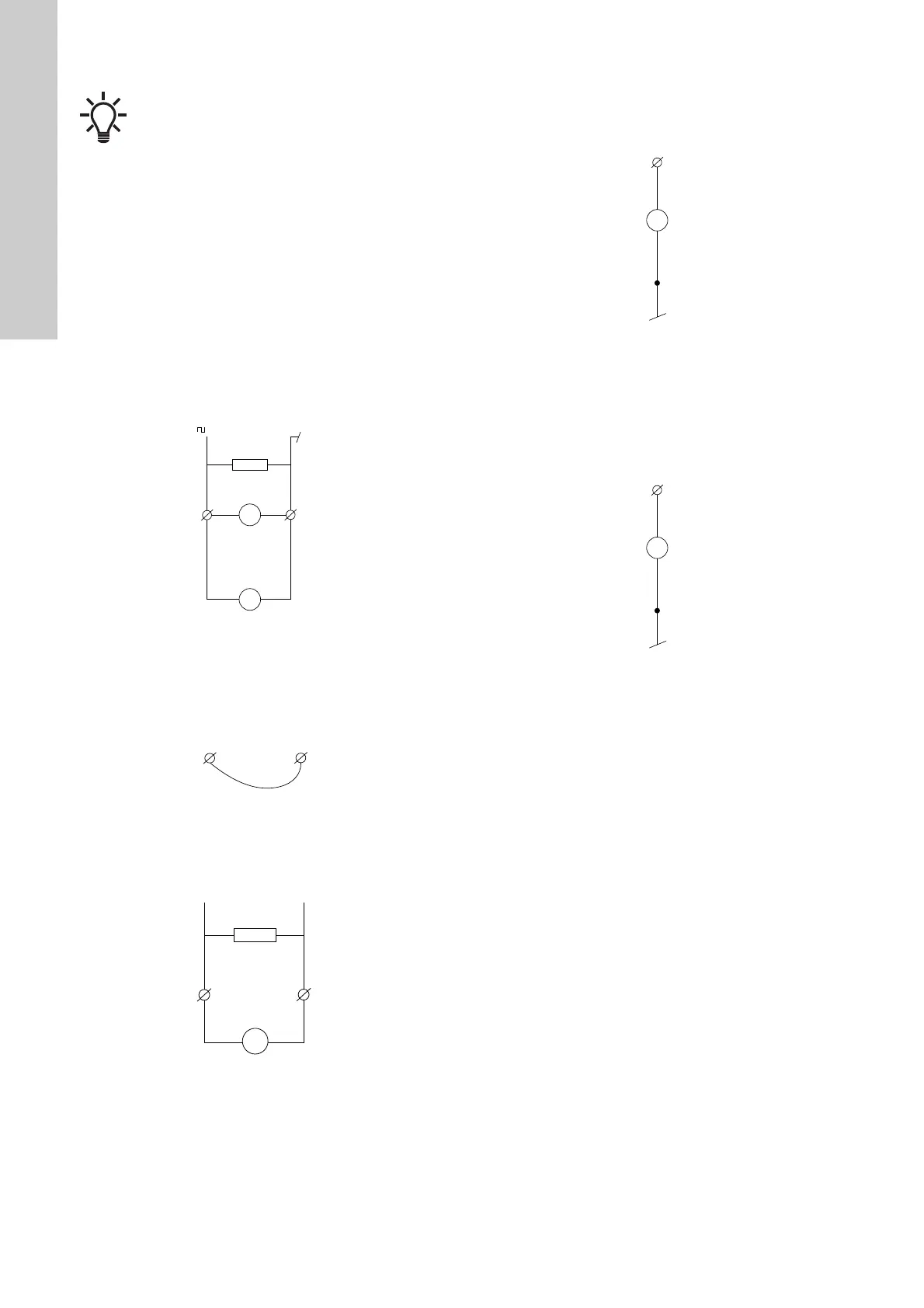

Fig. 58 Testing the digital input

Digital output, DO/open collector, OC

See the settings of the output in PC Tool.

Measure the output. If the value in PC Tool differs from the value

measured with the measuring instrument, remove the load. If the

values still differ, the module is defective.

The voltage of an active output is approximately 5 V.

Fig. 59 Measuring voltage on the digital output

LiqTec sensor

Connect a new LiqTec sensor to check the input. Immerse the

sensor into water and take it up. The motor must now report fault

within 20 seconds.

Signal relay

See the settings of the output in PC Tool.

Check if the relay reacts to the signals of the controller according

to the configuration of the controller.

CIM

Test the CIM module according to its manual.

Radio

If there are problems in the radio connection between Grundfos

GO Remote and the motor, remove the terminal box cover. See

section 7.1 Replacing the terminal box cover. Replace the control

panel if there is still no connection. See section 7.4 Replacing the

control panel.

Battery

Switch off power to the motor for a short period. When you switch

on the power to the pump again, adjust the clock.

Control panel (HMI)

Check the flat cable to the functional module. Replace the control

panel if the connection is correct, and it did not solve the problem.

Make a copy of motor settings.

TM05 7115 0613TM05 7116 0613TM05 7117 0613

TM05 7118 0613TM05 7118 0613

Loading...

Loading...