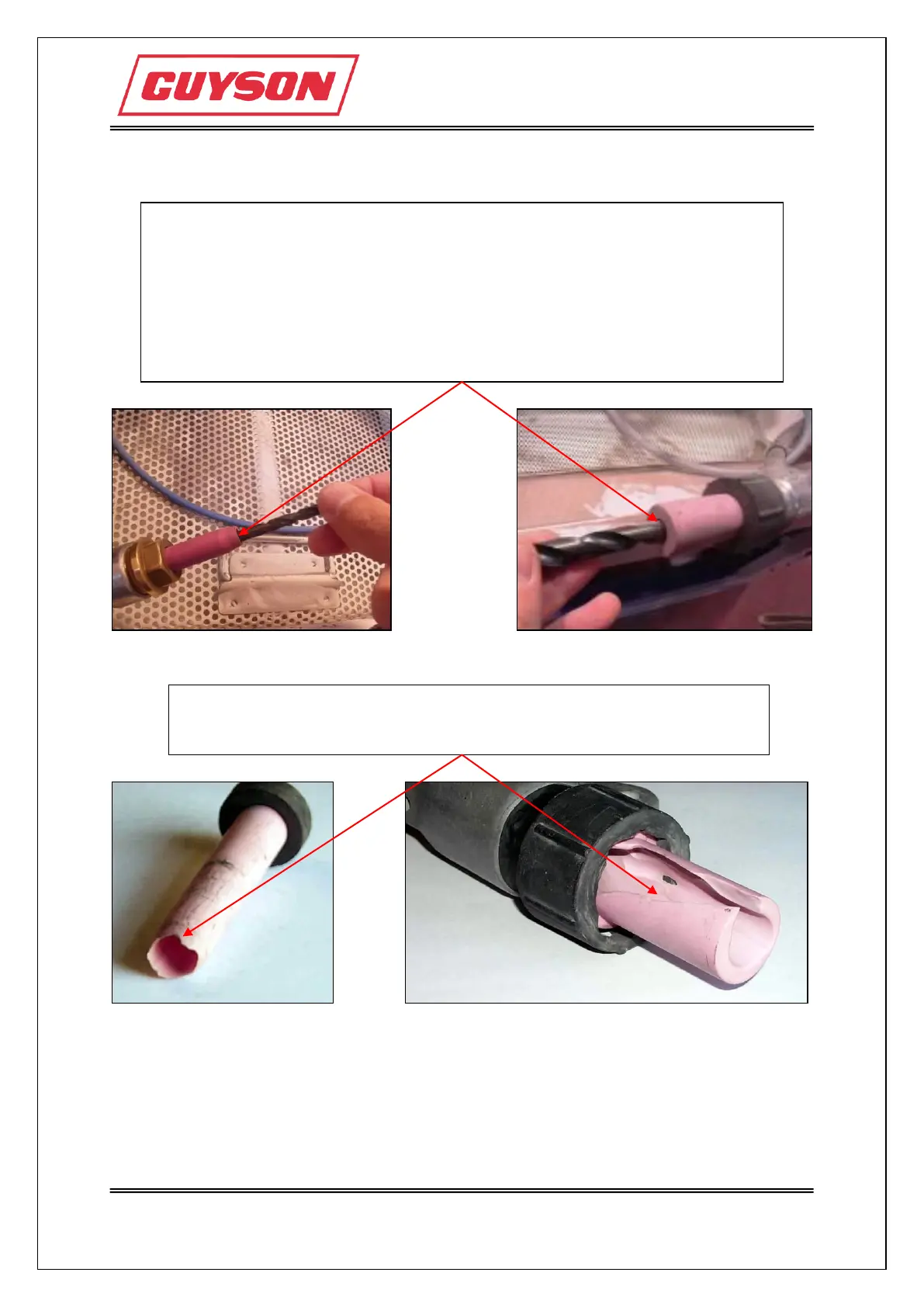

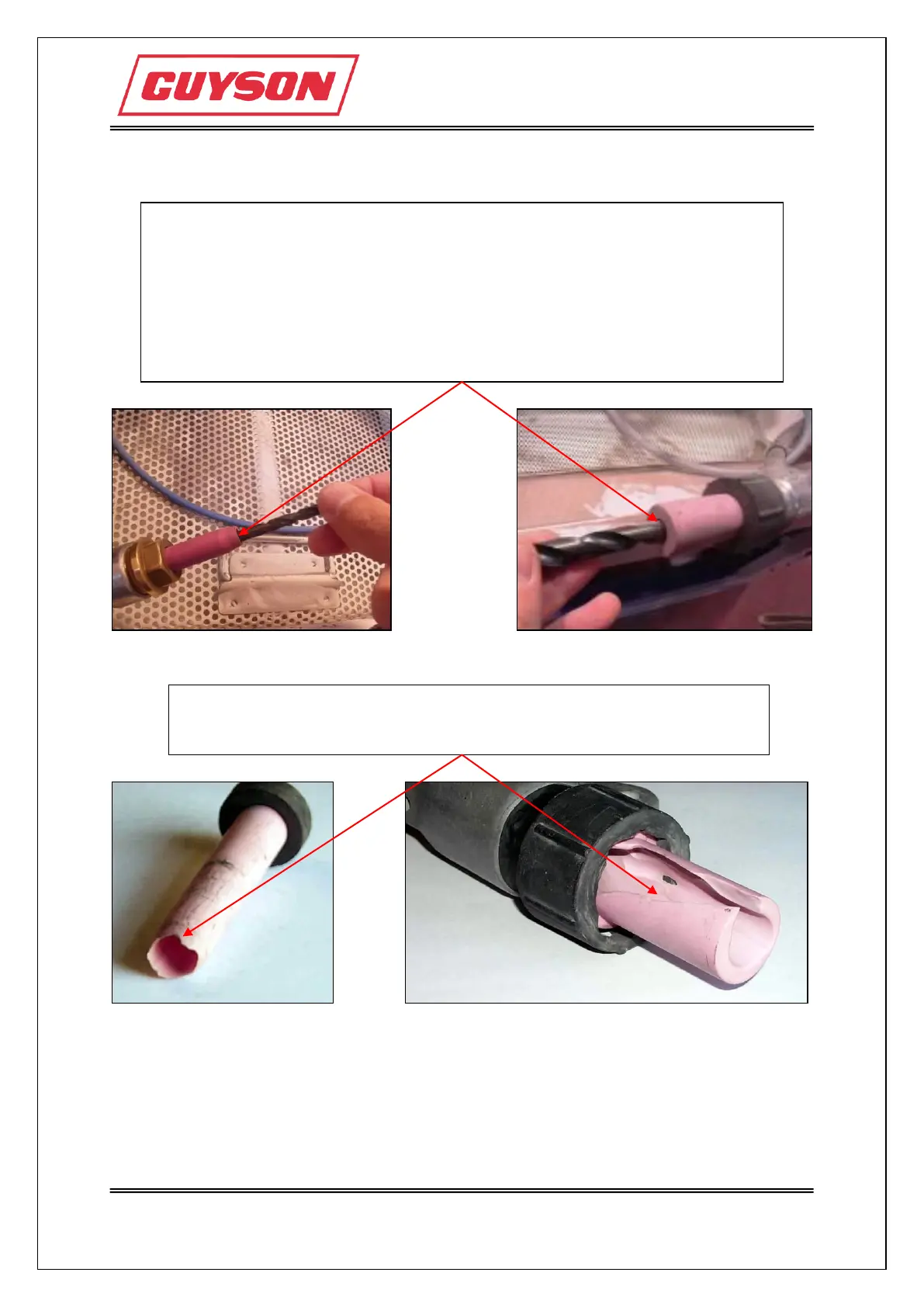

The pictures below show extremely worn nozzles. Your nozzle should not be

allowed to reach this state as it will decrease its blasting effectiveness and may also

damage the blast gun.

Inspect the blast nozzle for wear. When the bore size has increased by 20% (6mm bore

@ 20% = 7.2mm) then the nozzle needs to be replaced. The effective bore of a nozzle

can be quickly checked by use of a twist drill bit.

The nozzle should be withdrawn from the gun body after 8 hours blasting and rotated by

5° to avoid uneven wear.

CAUTION: CUSTOMER WEAR LIMITS ON SHOT PEENING APPLICATIONS

MAY NEED TO BE 10% WEAR LIMIT MAXIMUM

Loading...

Loading...