30

Warnings:

1.

2.

3.

TACK APPROPRIATE STEPS TO KEEP CONTAMINATIONS OUT OF THE LINES, WHILE

THESE LINE ARE OPEN TO ATMOSPHERE.

USE A OFMINIMUM 5% SILVER FOR COPPER TO COPPER CONNECTIONS.

USE A OF MINIMUM 35% SILVER FOR COPPER TO STEEL CONNECTIONS.

operation. Replace any if necessary.

J.

WHEN BRAZING, PURGE DRY NITROGEN THROUGH THE LINES TO PREVENT THE

FORMATION OF OXIDES.

G. Inspect all other components such as check valve and electrical components for proper

H. After all connections are made, open the service valves and pressurize to 150 psi with dry nitrogen,

I. After leak testing ,recover any test refrigerant.

Keep with (A) subpoints.

Use the largest connections and hoses possible to expedite the process.

charging procedures.

Evacuate through both high and low side connections to the system.

Break each vacuum with dry nitrogen to 3.0 psi.

K. Charge with clean, new or reclaimed R-22 refrigerant. Charge in accordance with proper

L. Re-check the system 24 hours of run time to verify the unit is free of acid.

Evacuate to a level of 1500 microns twice and 500 microns the last time.

7. Other Check Points

A. Verify the operating voltage is within the specified range.

E. Inspect all the other electrical components for proper operation.

F.

I.

! WARNING – Disconnect all electrical power to the unit before servicing. Disconnect power to

both the indoor and outdoor units. NOTE: There may be more than one electrical disconnect

switch. Failure to shut off power can cause electrical shock resulting in personal injury or death.

B. Check that all wiring connections are tight.

C. Verify that all fuses or circuit breakers are of the proper type and operational.

G. Verify all ducts and air moving device are sized and operate properly.

Verify all the system are in correct position.

D. Verify the air conditioning operates properly in cooling.

Verify the thermostat and subbase are correct and operate properly.

H. Verify the refrigerant piping is sized correctly and not pinched.

Leak test with liquid detergent. If a leak is found, repair it after removing the nitrogen, and recheck.

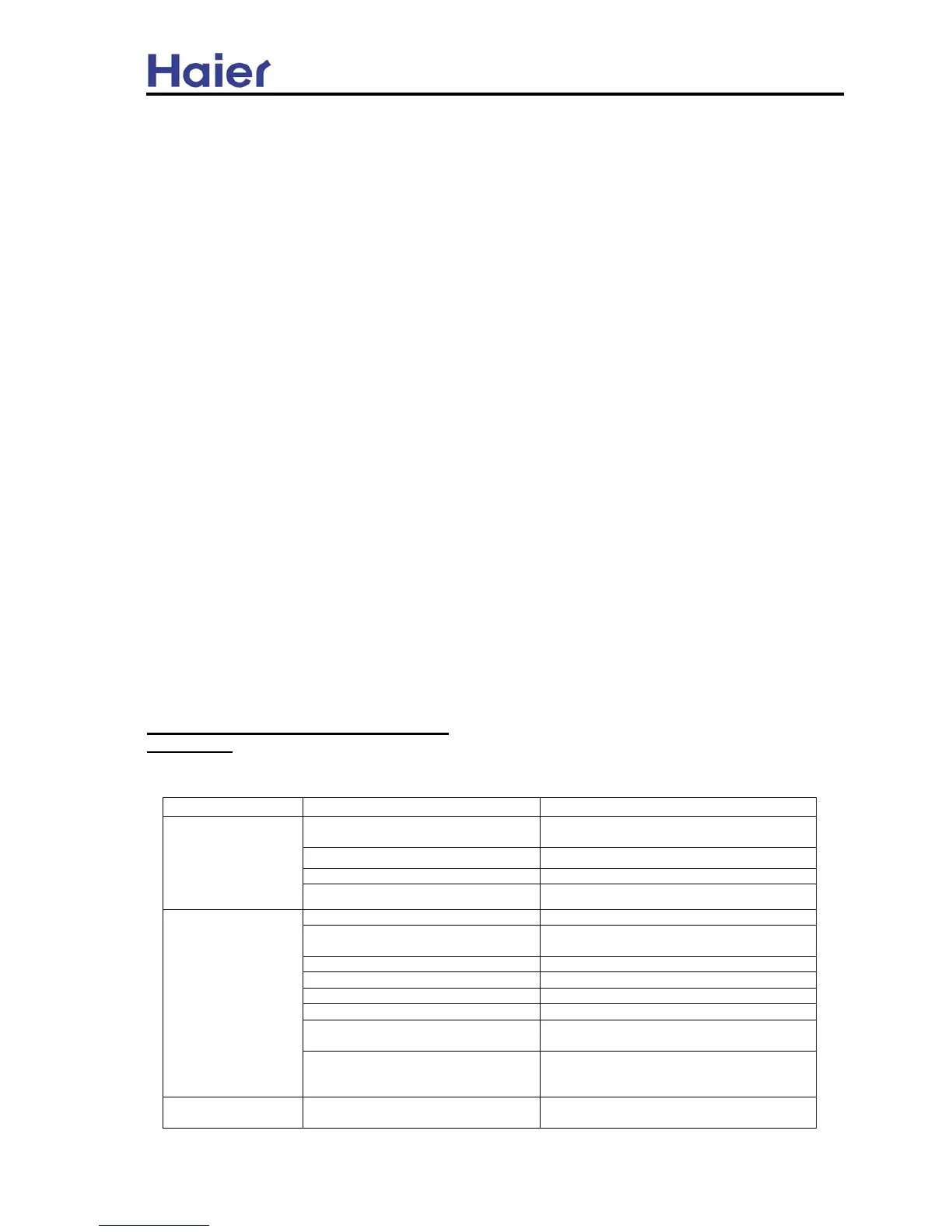

Symptom Possible Cause Remedy

Power off or loose electrical

connection

Make sure main switch is ON. Check and

tighten all connections.

Incorrect thermostat setting Set thermostat correctly

check the valve coil or replace it

No cooling/heating

replace it

Dirty filters Clean & replace

Indoor air blockage Check supply registers and return grills for

blockage.

Clear away leaves and other debris

Improperly sized unit Recalculate load

Improper airflow Check – should be 400CFM/Ton

Incorrect refrigerant charge Charge correctly per instruction.

Air, non-condensable or moisture in

system

Recover refrigerant, evacuate & recharge,

add filter drier

Insufficient Cooling

Incorrect voltage At compressor terminals, voltage must be

within 10% of rating plate volts when unit is

Water on floor or in

furnace trap

Defective 4-way valve

Blocked outdoor coil

Compressor without pump function

Blocked condensate drain and “P” Remove blockage and clean drain lines, verify

operation of condensate pump.

running.

Central Air Conditioning Model: Condensing Unit, HC13-D2

10.2 Troubleshooting Guide

Loading...

Loading...