21

Synchronised Pulsed Inputs (SPI)

Synchronised Pulsed Inputs are capable of

measuring the position, duty cycle, frequency

or state of a signal, as well as analog voltage

inputs.

These inputs are suitable for sensors such as

cam position sensors, fuel composition sensors,

road speed sensors and flat shift switch.

Synchronised Pulsed Inputs are compatible

with digital (hall effect or optical) and reluctor

(analog) based sensors, have a maximum input

voltage rating of 25V and can measure up to

50KHz Maximum frequency.

Specs:

• -10 to 10V digital input

• 0 to 5V analog input

• 1 million samples per second

• Selectable 1k pull-up to 5V

• -15 to 30V indefinite withstand

• 22.5kHz signal frequency max

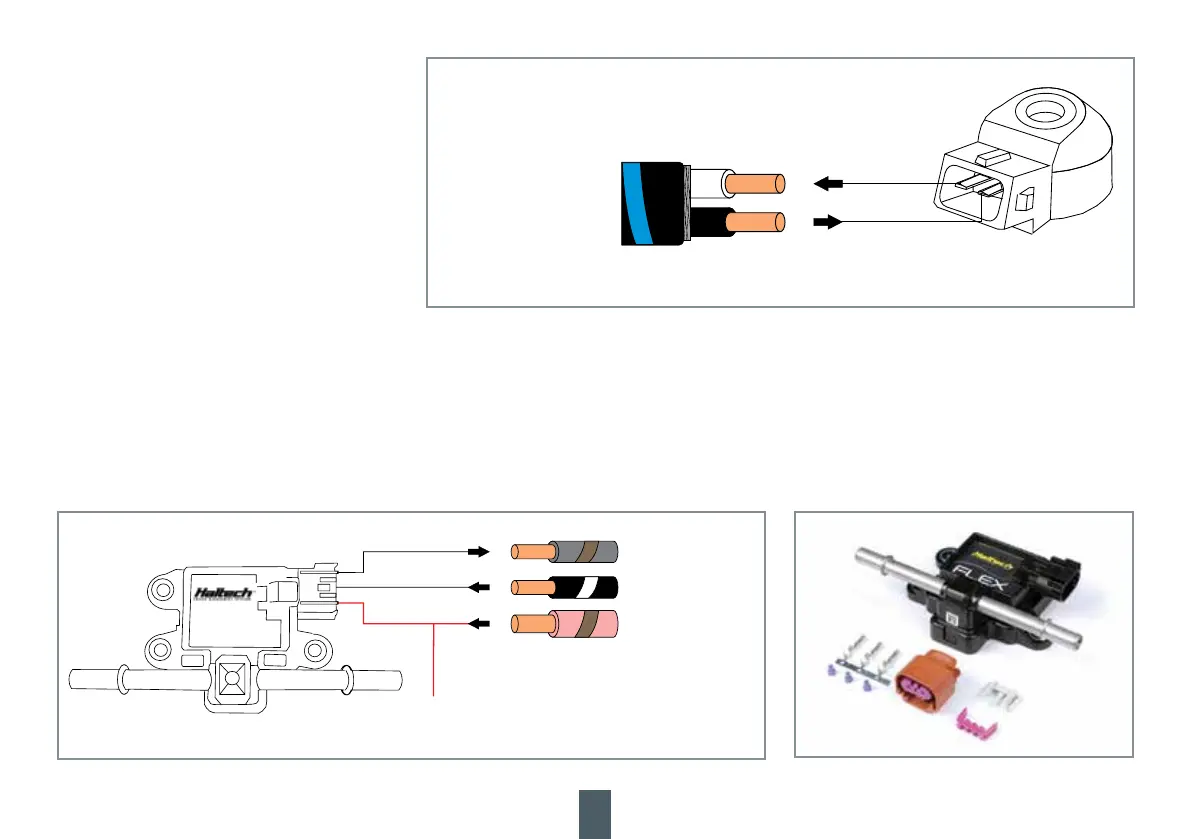

SPI

SIGNALGROUND

HCO

FREQUENCY BASED FLEX FUEL SENSOR

FLEX

FUEL SENSOR

TO OTHER

DEVICES

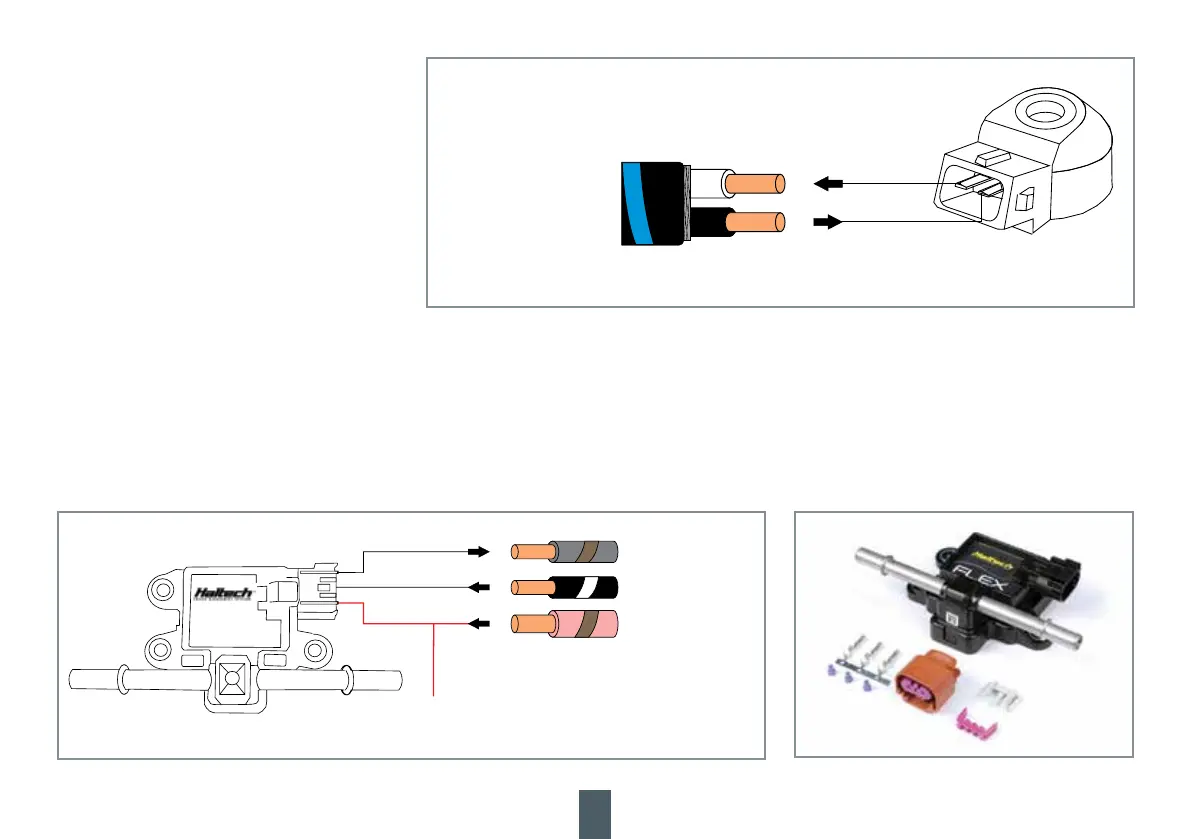

KNOCK

SIGNALGROUND

KNOCK SENSOR

Knock Inputs

A knock sensor detects engine knock and sends

a voltage signal to the ECU.

The NEXUS R5 ECU uses the knock sensor

signal to modify ignition timing if knocking

occurs. Knock detection can be performed by

the ECU by installing a compatible piezoelectric

knock sensor mounted to the engine block.

It is recommended that twin-core shielded cable

is used for knock sensors. Shields must be

terminated to battery ground at one end only.

Specs:

• -2.5 to 2.5V AC input only

• 160Hz to 48kHz signal frequency band

• +-3V indefinite AC voltage withstand

• 50V indefinite DC withstand

Example Wiring Connections

Example Wiring Connections

HT-011000

Loading...

Loading...