SPREADING

NOTE: Two speed apron drive and beater engage/disengage mechanisms are contained in a single gear-

box at rear of spreader. This gearbox is controlled by one rope leading to the tractor.

1. When ready to unload, before engaging PT

O, make sure that the gearbox is in the “low’’ position, with

the shifter dog all the way to the “low’’ side of the indicator slot.

2. Raise the hydraulic endgate (if so equipped).

3. Engage

the PTO slowly.

4. The apron speed may be increased from 4-1/2 fpm to 8-1/2 fpm (at 540 RPM) by pulling once on the

control rope until the shifter dog stops and locks into the “high speed’’ position. The beater will

continue to operate in this position.

5. When the spreader is almost empty, the bed can be cleaned out by again, pulling once on the control

rope until the shifter dog locks into the “clean-out/beater disengage’’ position. The beater

will stop, and the apron will continue to run in the “high’’ speed position, thus saving unloading time.

-11-

APRON

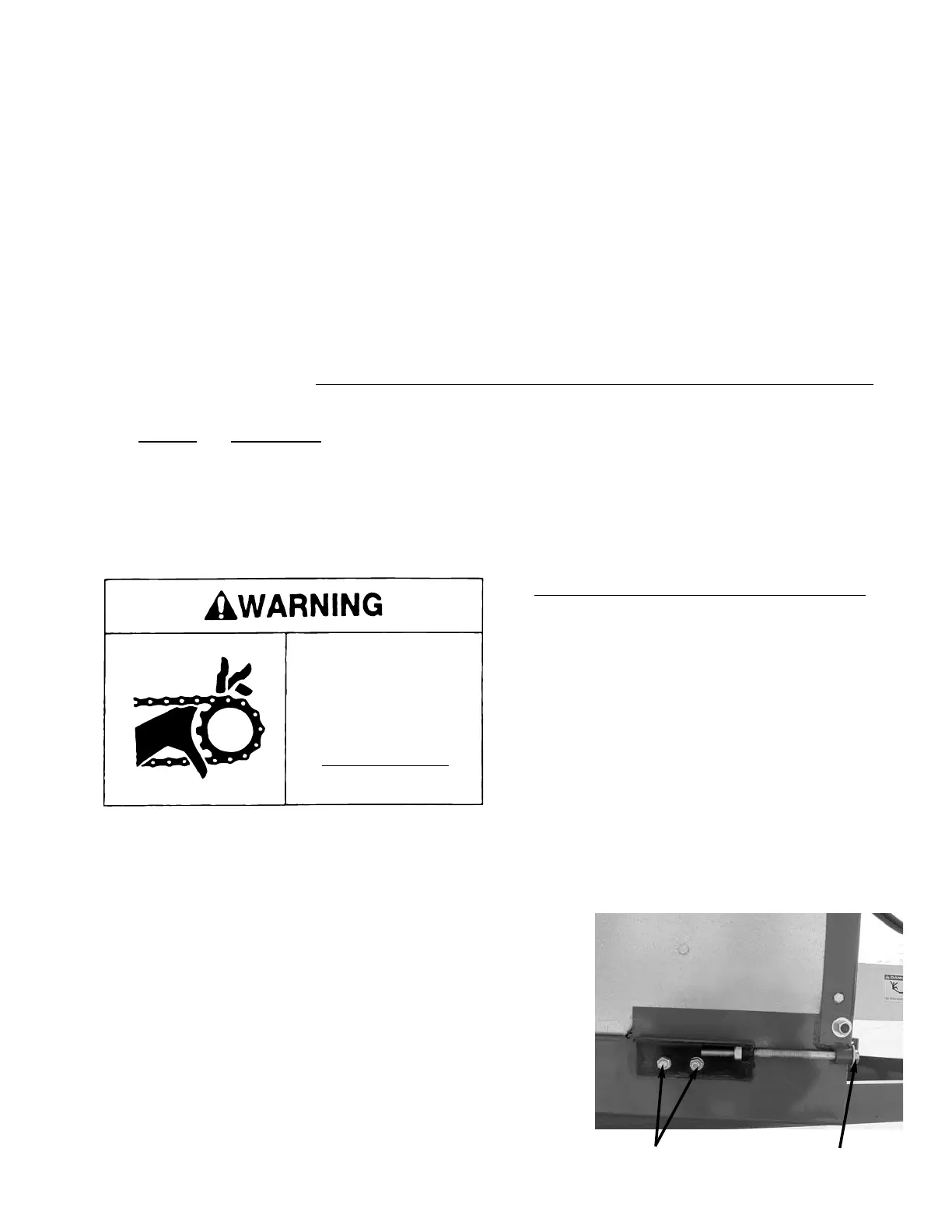

1. Adjust the apron by loosening the mounting bolts on

the chain slides on the outside of the frame. Mounting

bolts shown in the drawing.

2. Tighten the adjusting bolts until the apron has no sag

between the rear drive sprockets and chain slides

under spreader.

NOTE: Tighten the adjusting bolts (on each front corner)

equally on each side so that the apron slats run parallel with

the ends of the bed. The apron will be damaged if the

machine is operated with one end of the apron slats running

ahead of the opposite end. Do not tighten the apron chains

excessively.

DO NOT CLEAN

OR WORK ON THIS

MACHINE WITHOUT

FIRST DISENGAGING

POWER AND

SHUTTING OFF

TRACTOR ENGINE.

ADJUSTMENTS

FAILURE TO FOLLOW THE RECOMMENDED ADJUSTMENTS WILL VOID WARRANTY

ADJUSTING BOLTMOUNTING BOLTS

6. When spreader is empty, SHUT OFF PTO. With

the PTO off, pull the control rope once again, and

release it. The shifter will return to the “low’’

position, ready to begin unloading the next load.

DO NOT SHIFT FROM CLEAN OUT TO LOW

POSITION WITH THE PTO RUNNING.

7. Do not operate the spreader with a PTO speed

greater than 540 RPM unless the necessary

sprocket change has been made.

LOADING

In freezing weather, make certain that hydraulic tail gate (if equipped with one) is not frozen to the sides or

on the floor of the spreader. Make sure the apron chain is not frozen to the spreader floor or any lumps of

manure are frozen to the floor.

Begin loading the spreader at the front end and work toward the rear until loading is completed. Loading

this way permits the material to be spread uniformly. Loading front to rear is particularly important when the

spreader is loaded by a mechanical loader because this type of load requires more power to spread than

other loads.

When hauling extremely heavy material with a large portion of dirt, it may be necessary to reduce the load

size to prevent excessive shear bolt breakage. Never dump material onto the beater. Do not use extra side-

boards. Do not overload spreader. Overloading decreases spreading effectiveness. Do not load more than

15 inches above the beater.

Loading...

Loading...