3

A100b

JAN 2009

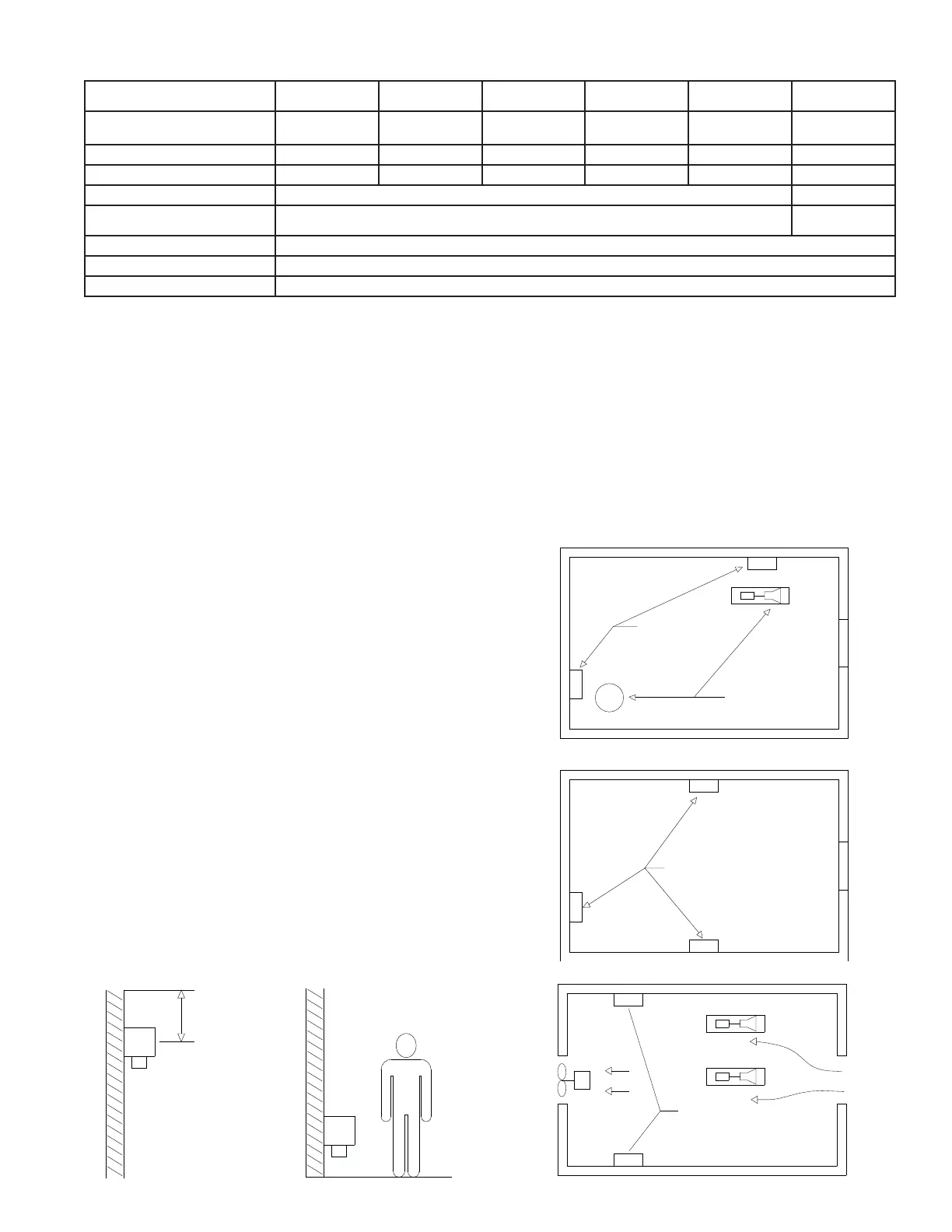

GAS SENSOR SPECIFICATIONS

BASIC STANDARD HARSH VENT LINE

EXPLOSION

PROOF

EXTREME

OPERATING TEMPERATURE

RANGE

0ºF TO 105ºF

(-17ºC TO 40ºC)

0ºF TO 105ºF

(-17ºC TO 40ºC)

-40ºF TO 105ºF

(-40ºC TO 40ºC)

-40ºF TO 105ºF

(-40ºC TO 40ºC)

-40ºF TO 105ºF

(-40ºC TO 40ºC)

-60ºF TO 105ºF

(-51ºC TO 40ºC)

OPERATING CURRENT @ 24V DC

230mA/6W 50mA/1W 280mA/7W 280mA/7W 280mA/7W 1900mA/46W

OPERATING CURRENT @ 24V AC

460mA/11VA 100mA/2VA 560mA/13VA 560mA/13VA 560mA/13VA 2100mA/50VA

VOLTAGE REQUIREMENTS

12-24V AC/DC* 24V AC/DC*

HUMIDITY RANGE

(NON-CONDENSING)

0-95% 0-100%

MAX. LOOP RESISTANCE

1000 OHMS

OUTPUT

4-20mA, 0-5V, 1-5V, 0-10V, 2-10V DC

4-20mA SIGNAL OUTPUT

Isolated, 2 wire

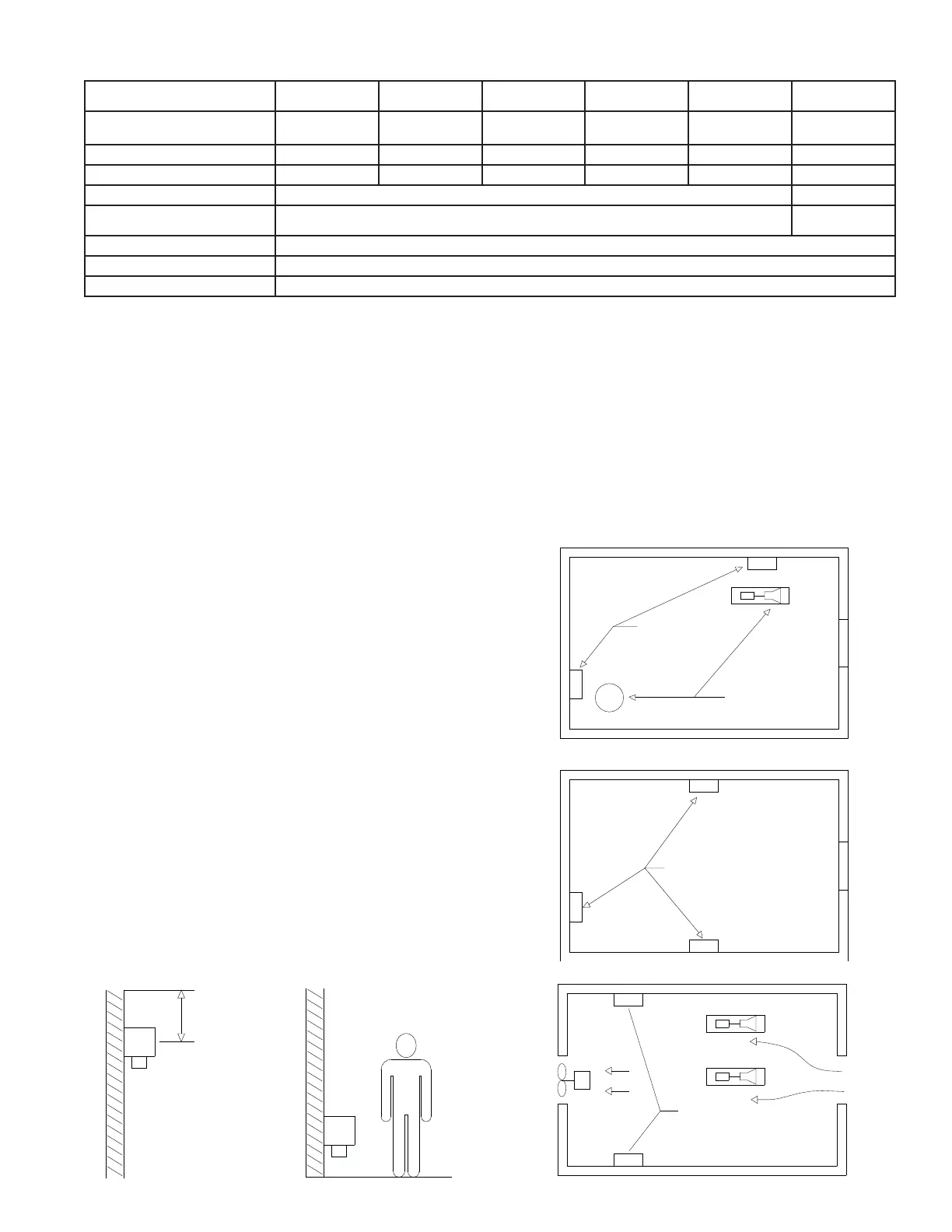

PLACE SENSOR

NEAR OPERATING

EQUIPMENT

OPERATING

EQUIPMENT

PLACE SENSORS

AROUND PERIMETER

OF LARGE ROOM

AIR FLOW

PLACE SENSOR(S)

BETWEEN EQUIPMENT

AND EXHAUST FAN

12" - 24" FROM CEILING

LIGHT GASES (AMMONIA)

HEAVY GASES (CO2, HALOCARBON)

MOUNT NEAR GROUND LEVEL

GAS SENSOR LOCATION

Sensors should be located in an accessible area

for maintenance and testing, but away from moving

equipment that could accidentally come in contact with

the sensor. Avoid thermal extremes (close to heaters)

and do not place unprotected in direct, strong drafts/

airflows, near exit doors, or areas where falling water or

condensing moisture are present. If high humidity is

always present, power up the unit as soon as possible,

as long term exposure can shorten the life of the gas

sensing element. Select the unit for harsh environments

where a condensing atmosphere may be present. In

blast freezers, mount the gas sensor below the coil to

avoid high moisture and steam during defrost.

The two generally accepted methods of locating sensors

are “Point” and “Perimeter” detection. “Point” detection

is where sensors are located near the most likely sources

of leakage. “Perimeter” detection is where sensors

completely surround the area in question. The size and

nature of the area will help to decide which method is

the most appropriate. Air flow should be considered

in a ventilated room. Place sensors downstream of

potential leak points.

Any sensor which is to be used for detecting a gas

with a vapor density greater that one (i.e. heavier

than air) should generally be located nearer ground

level. Conversely, for any lighter than air gases such

as ammonia, the sensor needs to be located higher up.

Typically ammonia sensors are mounted 12˝ - 24˝ (.3 to

POINT DETECTION

PERIMETER DETECTION

VENTILATED ROOM

MOUNTING HEIGHT OF SENSORS

.5m) from the ceiling. Sensors should not be located

too close to the ceiling as hot air trapped under the

ceiling may act to buffer the target gases from reaching

the sensor.

The number of sensors in each area is a function of local

codes and regulations and the customers’ guidelines

for gas detection.

*AC or DC user selectable. See pages 6 and 7 for configuration.

Loading...

Loading...