4

A100b

JAN 2009

GAS DETECTION SYSTEM CONFIGURATIONS

There are a number of typical installation configurations to meet national and local codes.

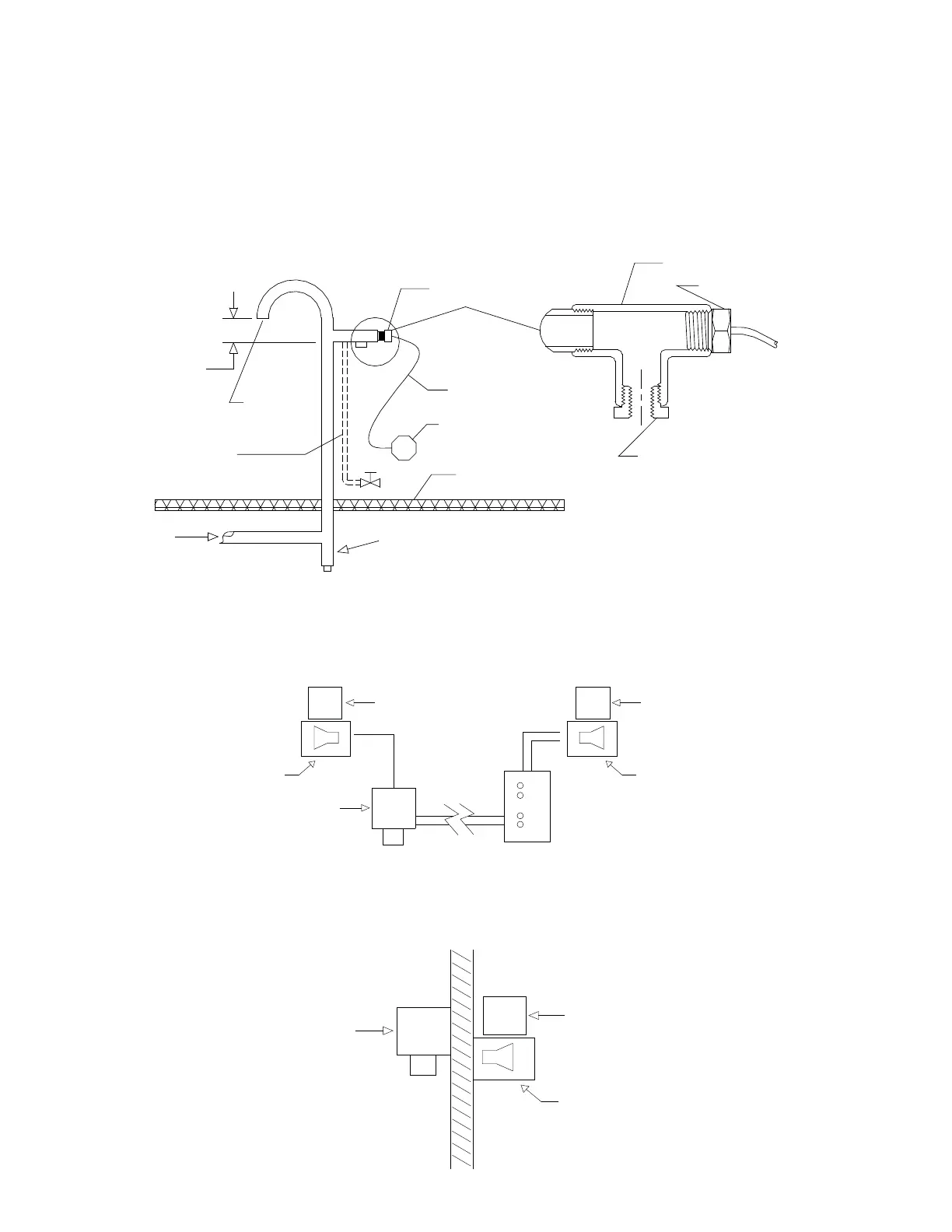

RELIEF VALVE VENT LINE

Often the vent line is extended high above the ground or roof. The sensor element can be installed near the outlet of

the vent line and the gas sensor electronics mounted at a convenient height for servicing. A small length of tubing

can be run for injecting test gas near the sensor element. Install a plug with a small opening to allow a small air flow

to clear fugitive gases and detected gas after a release. Hansen recommends the alarm setting at 5000 PPM.

For water diffuser systems where the relief valve vent piping is diverted into a water diffusion tank, install the vent

line sensor on the diffusion tank exhaust vent, not on the piping to the diffusion tank.

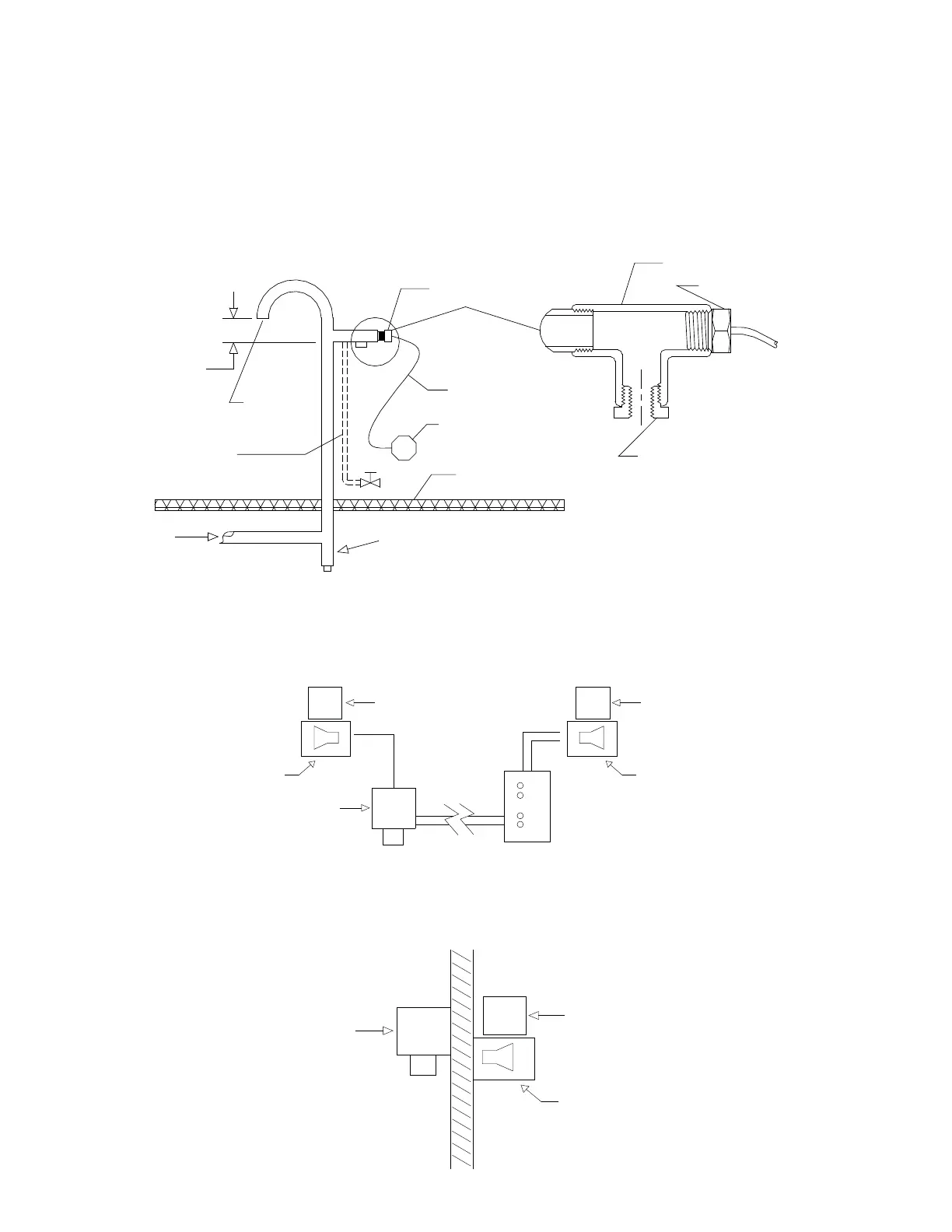

LOCAL AND REMOTE VISUAL/AUDIBLE ALARM

Sometimes it may be advantageous to have both local and remote displays and alarms. A display/alarm control

inside or just outside of a room can be monitored and the same display/alarm or a Hansen monitor in the control

room can also alert the operator to an abnormal condition in the plant.

STAND ALONE CONTROL

The Hansen Gas Sensor can operate as a stand alone device. All that is needed is a 24V AC/DC power supply for

the gas sensor and auxiliary devices for light, horn or digital readout, such as the Hansen GAS Alert System.

INDOOR OUTDOOR

VISUAL

AUDIBLE

GAS

SENSOR

VISUAL

UDIBLE

LARM ALARM

ALARM

ALARM

INDOOR OUTDOOR

VISUAL ALARM

AUDIBLE ALARM

GAS

SENSOR

INSIDE SPACE OUTSIDE SPACE

GAS SENSOR ELEMENT

10' (3m) CABLE, MAX

WEATHER PROOF

GAS SENSOR ELECTRONICS

RELIEF LINE DISCHARGE HEADER

DRIP LEG

INSTALL

GAS SENSOR

ELEMENT WITHIN

2' (.7m) OF

DISCHARGE

VENT LINE APPLICATION

PROTECT

EXIT WITH

SUITABLE

OPTIONAL TUBING

LINE For "BUMP" TESTING

GAS AND AIR PURGE

ROOF LINE

PIPE TEE

GAS SENSOR ELEMENT

1" X 3/4"

TO ALLOW A SMALL AMOUNT OF

AIR FLOW TO CLEAR DETECTED

GASES AND AVOID FALSE ALARMS

REDUCING BUSHING

SCREEN

Loading...

Loading...