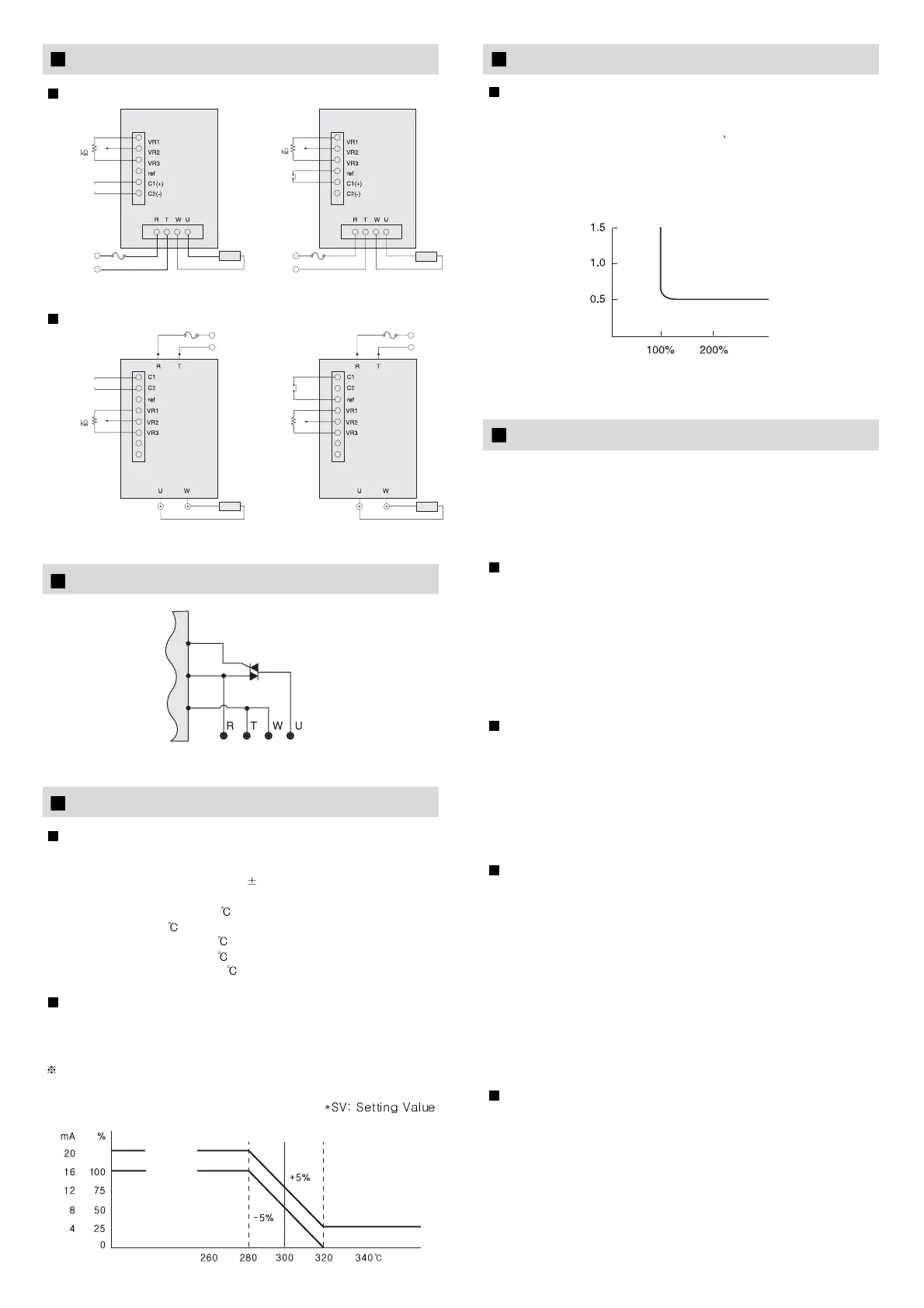

Internal Structure

How to operate

Wiring Diagram Function Explanation

Function Explanation

25 ~ 70 A

Detecting Over-current Function

ON-OFF Control Method

Continuous Control Method

Constant Voltage (Current) Control Method

Constant Power Control Method

100 ~ 200 A

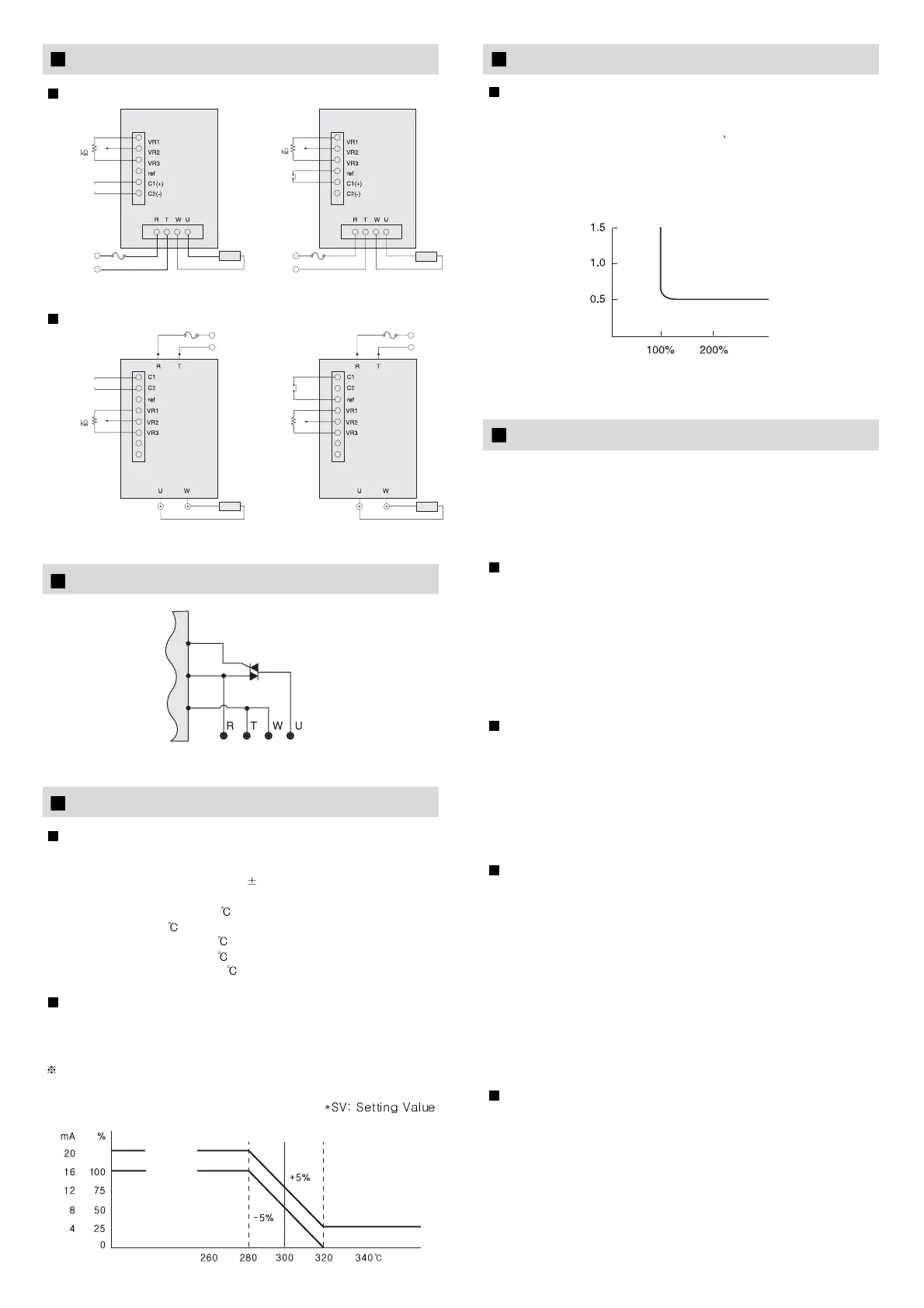

Temperature Controller for Current Output

Thyristor Power Regulator is operating as

following the signal of 4~20 mA DC from the above

This is not followed the method of the relay output which is used up to

the date. This controller outputs the current of 4 ~ 20 mA DC(Internal

Standards) from the setting value of 5 %.

For example

Temperature Controller for 400

If Setting value = 300

It outputs 20 mA DC up to 280

It outputs 12 mA DC up to 300

It outputs 4 mA DC beyond 320

Our Thyristor power regulator employs electronic over-current circuit. In

the case of flowing over-current in the load, as the detecting over-

current circuit is operating, it stops the gate s signal of the control

element, Thyristor, so that the control element,

Thyristor, becomes “OFF.” At this moment, the front over-current

indicator (OC) of the Thyristor power regulator will be lighting. At this

time, by using the alarm contact, you can use the alarm.

Control Method of Thyristor Power Regulator

By the function of Temperature Controller, it can be divided into two ways, ON-

OFF control method and continuous control method.

By using Thyristor power regulator, a temperature controller device can be used

ON-OFF, continuous control or etc. as only converting the input signal of the

gate. Specially, for an electric furnace which contains high thermal capacity or a

control target which is slowly responded, these methods are suitable.

This method is operating when the current temperature is higher or lower the

setting temperature of the controller and it has a simple structure and economical.

However, the operating area is ON-OFF around the setting value so there is the

up and down occurrence by 2-position operation.

To eliminate the occurrence, we need the fact that if the adjusting sensitivity

becomes narrower then there might be the output’s tremble occurrence or it can

be affected by the noise and if the adjusting sensitivity, Dead Band, becomes

wider, the accuracy can be a problem. But, if the width of the up and down,

cycling, occurrence is within the allowable temperature width then ON-OFF

control can be applicable.

The proportional operation is the basis as the continuous control of electrical

furnace and this is the method which is applying the proportional outputs to the

heating element in the furnace in accordance with the deviation signal magnitude

after comparing the temperature in the furnace with the setting value.

If applying only the proportional control (P), theoretically, there is unavoidable

error by the circuit constant. To prevent this error and to obtain more accurate

control, it is more effective to employ the integral operation (I) or to make the

response time faster, it is more to use the differential operation (D). Therefore, P.I

or P.I.D control is generally used.

For the case of doing an individual or batch control the temperature of the target

which the temperature detection is difficult, generally, the constant voltage control

is employed. This method controls the average value of the voltage or the

effective value which applies to the furnace constantly with ignoring many little

disturbances about the controller. Therefore, instead of getting the return signal

from the controller of the temperature detection type, detect the furnace°Øs

temperature and then make it as the signal of the power regulator it becomes the

constant voltage control.

At this time, you have to decide whether you use the average value or the

effective value to control. Since the heating effect of the heater is controlled by

the effective power, the latter one looks more suitable. However, generally, the

detection of the effective value of the voltage in comparison with the detection of

the average value it requires more high technology so it costs more. Therefore,

for the target which is not required the high accuracy, normally, the average value

control is used.

Unlike the purely resistive heating element, the resistances of the silundum

heating element and the molybdenum heating element are changed steeply

according to the operating or elapse of the time. Even though using the control

method which is mentioned before, it remarkably shortens the element’s lifetime

as it becomes overpowered or underpowered. The constant power control is to

solve for this faulty matter. To control the constant power, detect the effective

power which can mean to obtain it by multiplying the apparent power and the

power factor as using non-linearity of the combined circuit after detecting the two

elements of the effective voltage as well as the effective current.

Therefore, it is the same way of the general control method except installing the

above power detector into the front of the gate control area from the constant

power control device.

It outputs the power like the bottom

4 mA 0 %, 8 mA 25 %, 12 mA 50 %, 16 mA 75 %, 20 mA 100 %

refer to the picture 1

Loading...

Loading...