22PC 45 Corn/Pellet Stove

3-90-02686R29_05/14

Burn Pot Maintenance

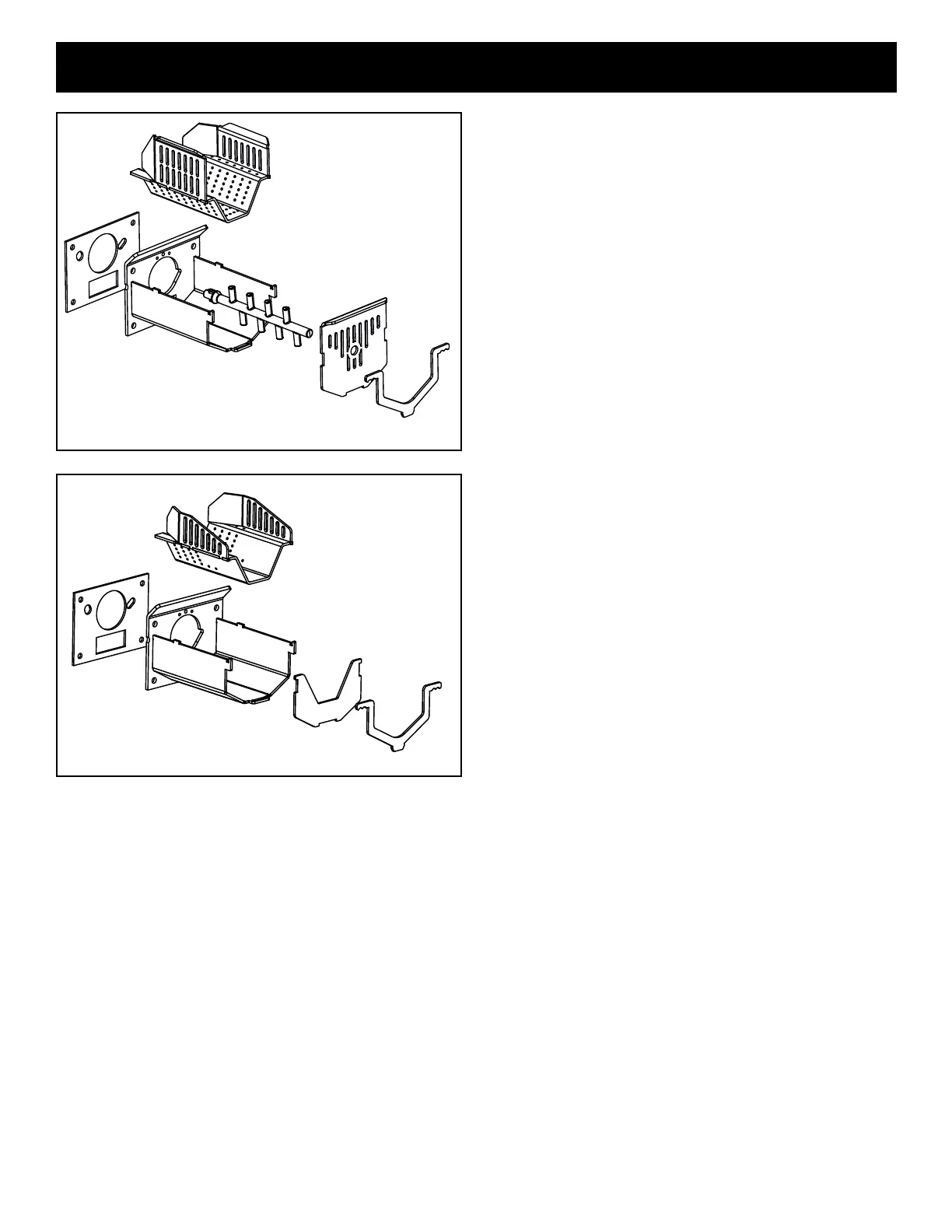

Corn or Pellet Burnpot Setup

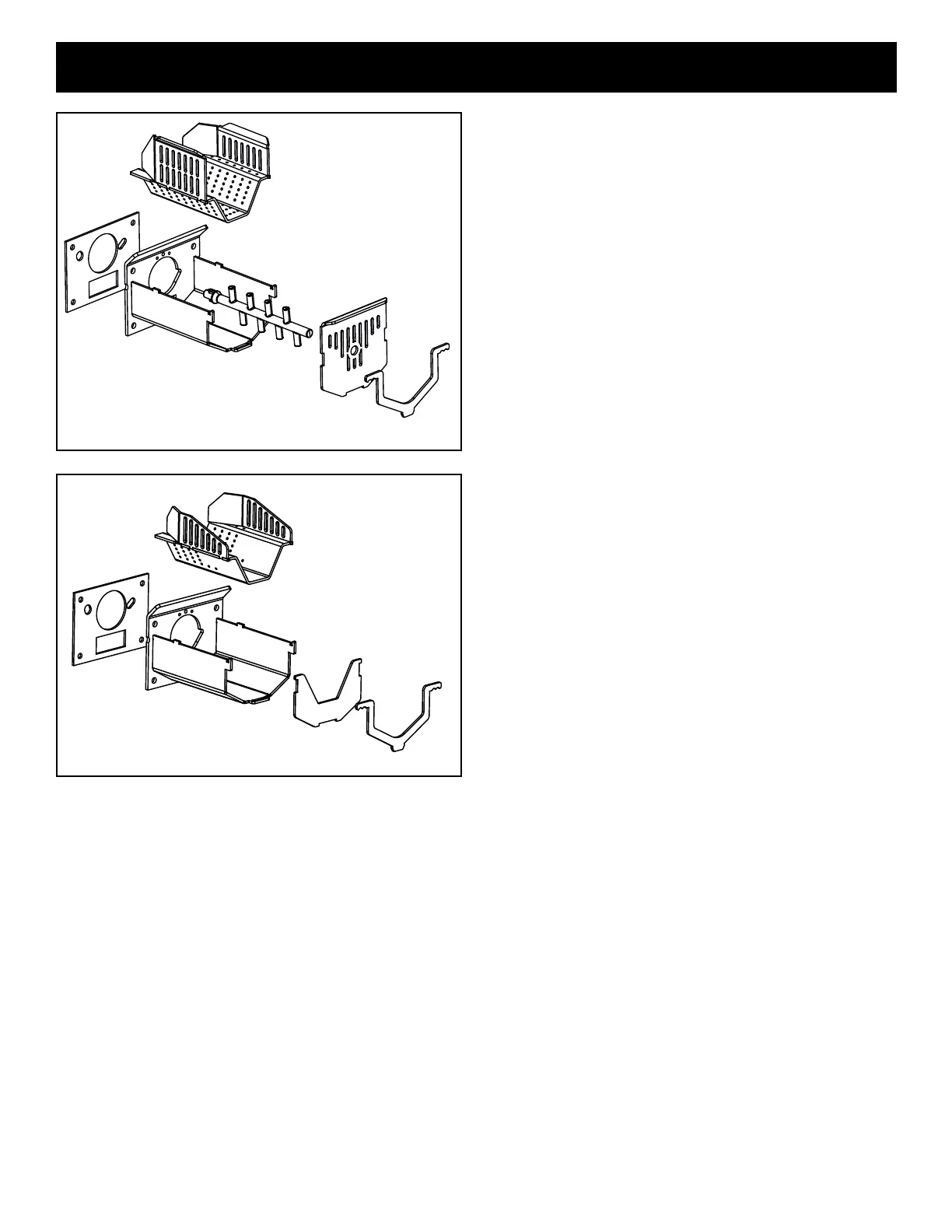

Pellet "only" Burnpot Setup)

Burn Pot Cleaning and Maintenance

1. Besurethestovepoweristurnedoff.

2. Liftupandremovethefrontplatelockandfrontplate.Set

asidethefrontplate.

3. Removetheaugerextensionbypullingtowardyou,then

setaside(cornburnpotonly)

4. Removeburnpotgrateandsetaside.

5. Cleanallnesanddebristhathasaccumulated.

6. Installthe"cleaned"burnpotgratemakingsurethe2holes

lineupwiththe2tabsintheburnpothousing.

7. Now install the spare "clean" auger extension into the

augershaft.Makesurethereisn'tanycornordebrisin

theshaftopening.Thiswillpreventtheaugerextension

frombeingfullyinsertedintotheshaft.

8. Aligntheaugerextensionthroughtheholeinthe"clean"

frontplateandplacefrontplateagainsttheburnpotgrate

andhousing.

9. Installthefrontplatelock.

NOTE:Aftercleaningoftheseparts,inspectforexcessive

wearandreplaceasneeded.

Cleaning of Burnpot Parts

Cleaningcanbeperformedin2basicways:

1.Becausethecornslagbuildupwillabsorbmoisturefromthe

airwhencool,thepartscanjustbeleftexposedforseveral

daysandtheslagbuildupwillcrumbleoffoftheparts.

2.To accelerate this process,theparts can be soaked in

water for approximately 30 minutes (depending on the

amountofbuildup,theycouldbecleanedinlesstime).

NOTE:Cleaningof thesepartsisnotnecessaryuntilyou

seethatthereisanoticeabledecreaseinthequalityofthe

ameintheburnpot.Example:Unburnedfuelbeingpushed

overtheburnpot.

Safety Features

Thelowdraftsensorwhichisavacuumdifferentialswitch,monitorsthenegativepressure(draft)inthereboxthrougha

portontherearofthefeeder.Poordraftcanbecausedbyblockageintheexhaust,excessivebuild-uponthecombustion

blowerfanblades,afailedcombustionblower,oradoororotheropeningtothereboxnotsealedproperly.

Thecircuitboard ismonitoringtheposition ofthisswitch. Ifthisswitchwere toopen,powerto theigniterandthe feed

motorareinterrupted.Theindicatorlightsforthesecomponentsmaybeilluminatedeventhoughpowerisnotowingtothe

components.Besurealldoors,includingthehopperlid,aresecurelyclosedwhenoperatingtheappliance.

Fig. 38

Fig. 39

Loading...

Loading...