12

Do not burn any fuel other than wood, such as

charcoal, which can cause increased carbon monoxide

production or overfiring. Never use highly volatile

substances in your stove, such as gasoline, which could

cause an explosion.

When solid fuels are burned completely, they produce

water and carbon dioxide. However, in long slow

burns, a substantial amount of carbon monoxide may

be produced. If allowed to build up, carbon monoxide

(which is odorless) can prove fatally poisonous. Proper

ventilation and draft will prevent this from happening. If

you smell smoke, turn up the air control lever setting,

and thoroughly ventilate your dwelling. During future

burns, be careful not to overload the stove with fuel, so

you will not be tempted to constantly operate at a low

air control setting.

Other causes of poor ventilation or draft are icing,

exhaust fans, a blocked outside air inlet, and room

air starvation. If your stove is sluggish and you get

occasional odor, check these possibilities and increase

the air ow in your home.

When venting your TL300 using a prefabricated

chimney, be sure to contact local building code

authorities, and to follow the manufacturer’s

instructions exactly. Use only the manufacturer’s

parts; do not use makeshift installation techniques. All

prefabricated chimneys must be tested to either the

U.S. or Canadian high-temperature standards, UL 103

or ULC S629.

If you plan on using a pre-existing masonry chimney,

have it thoroughly inspected and cleaned. Any faults

which make the chimney unsafe and unusable must be

repaired prior to use. These can include improper height,

structural defects, blockages, inadequate clearance to

combustibles, unsealed openings into other rooms of

the house, signs of creosote or smoke leakage, a loose

or absent clean-out door, or absence of a liner.

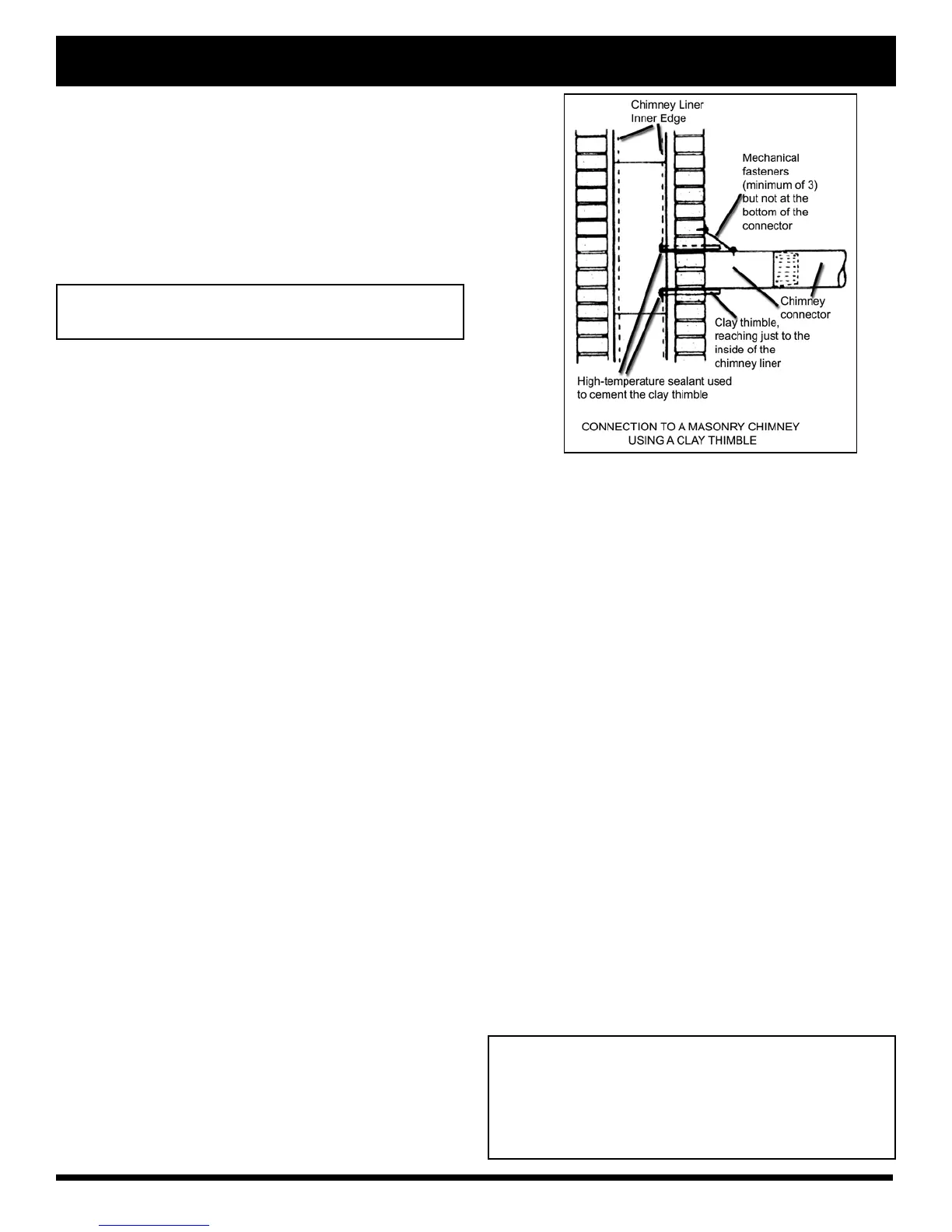

When connecting to a masonry chimney, several

provisions are standard. First, whether the chimney

connector is vented to the chimney through a thimble

or a breech pipe, neither must pass beyond the inner

surface of the chimney liner, and both must be rmly

cemented in place with refractory cement. (A thimble is

a masonry pipe which is inserted through the chimney

wall, and is frequently the preferred method; a breech

pipe is a piece of steel pipe used the same way.) In

Canada, a breech pipe has ridges or protrusions to lock

it rmly into the refractory cement. In either case, the

chimney connector vents to the chimney through the

thimble or breech pipe.

Using a thimble, the connector slides completely

inside the masonry to the inner edge of the ue liner,

and may be easily removed for chimney and connector

inspection. A breech pipe must extend at least 2" (50

mm) into the room, so the connector can be attached

with sheetmetal screws.

In some situations, a code compliant chimney origi-

nally used for a masonry replace may be used to install

your TL300. In addition to the requirements found in

the previous paragraphs, it is important to be aware

that all clearances must be met, including those from

the chimney connector to combustibles. Do not forget

to include oor protection in your plans. (See Clear-

ances and Floor Protection in this section.) Since many

replaces have exposed wooden mantels and trim, pay

special attention to the clearances necessary to these

materials.

If your replace chimney is behind a combustible wall,

you must use an approved wall pass-through system

to gain access to the masonry chimney. The chimney

connector must enter the chimney at a place where it

is lined, and the replace must be made inoperable.

For example, you might remove the damper, replacing

it with a secure, airtight, noncombustible seal (remov-

able for inspection); this also satises the requirement

that no room air must be allowed to enter the chimney.

Loading...

Loading...