4A

1

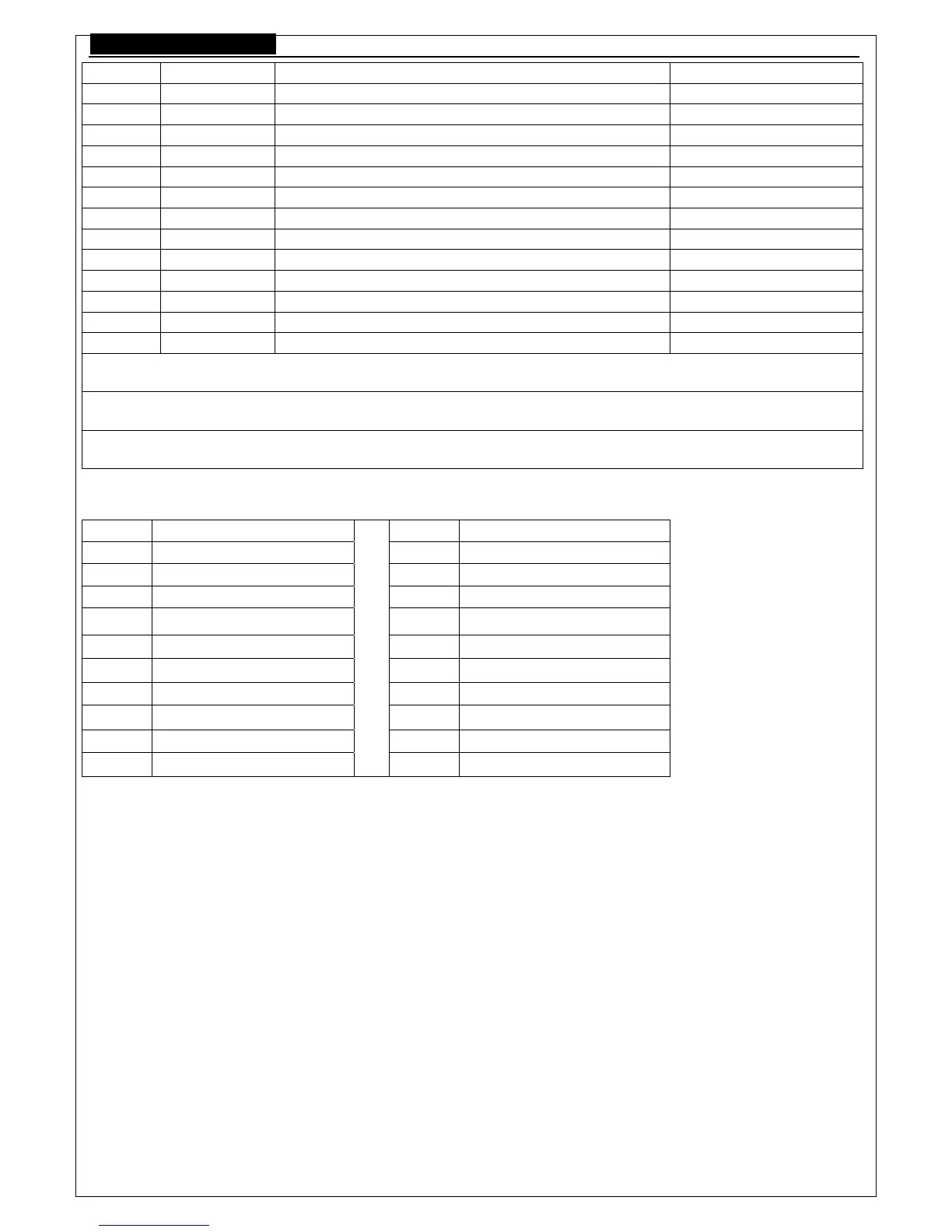

Aux input voltage calibration

$204B ――― $205E P-sensor data, ordered according to the resistance(0.1Ω) from big to small and resistance-related

value-resistance

$205F ――― $2072 T-sensor data, ordered according to the resistance(0.1Ω) from big to small and resistance-related

value-resistance

$2073F ――― $2086 oil position sensor, ordered according to the resistance(0.1Ω) from big to small and resistance-

related value-resistance.

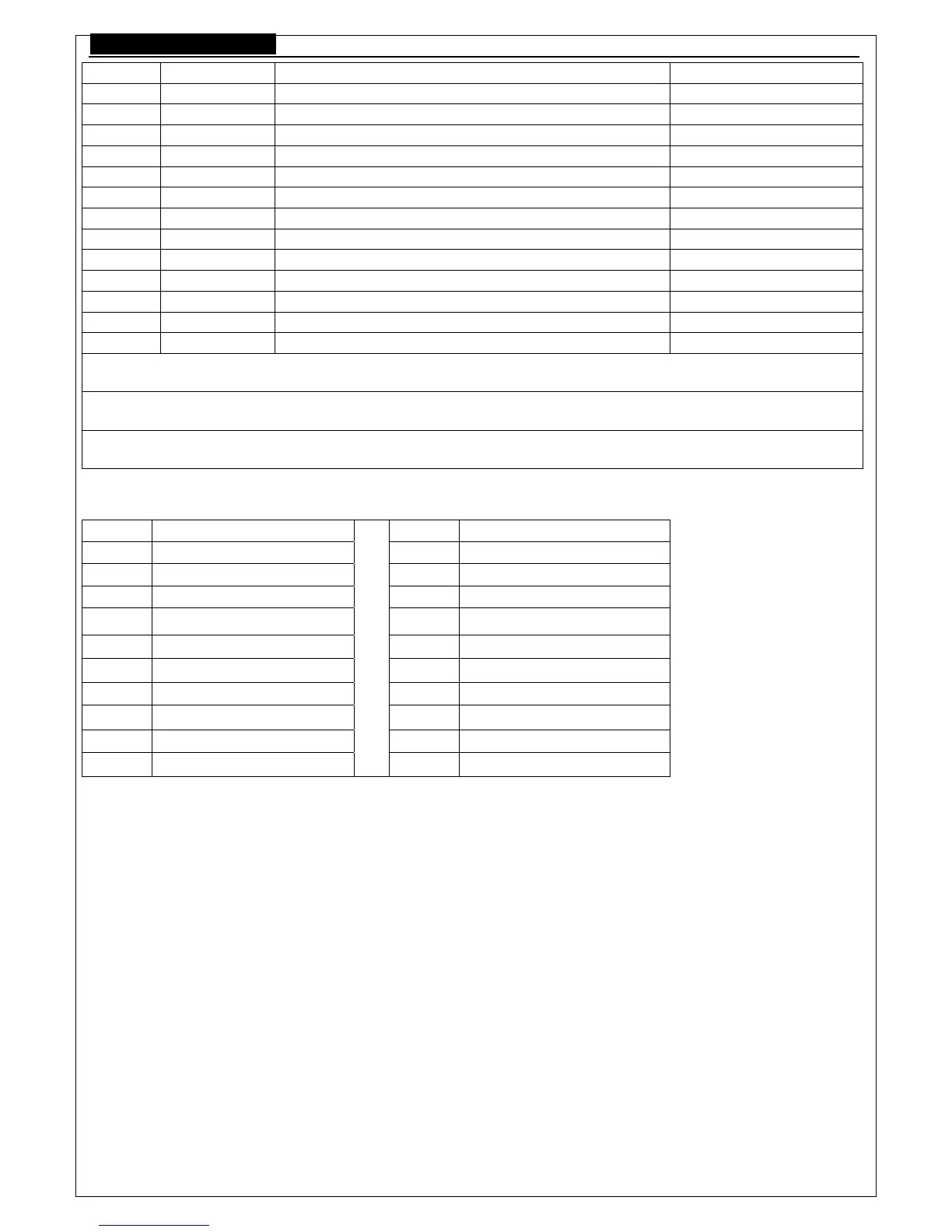

Note: fault code table

Code Fault Code Fault

0 NO ERROR 10 BATTERY LOW

1 NO PICKUP 11 CHARGE FAILURE

2 OVER SPEED 12 V LOW

3 UNDER SPEED 13 V HIGH

4 O-SENSOR OPEN 14

5 LOW OILPRESS 15

6 T-SENSOR OPEN 16 I HIGH

7 COOLANT TEMP 17

8 START FAIL 18

9 STOP FAIL

19

11 Preparations

11.1 To confirm that the controller has installed and fixed properly, and the installation ambient must accord with

installation demand

11.2 To confirm the whole connecting of control lines accord to the electric norm, and confirm to the typical connecting

diagram of “1.3”. Especially the DC power supply must add fusing element safety wire to protect, and the polarity must be

right. Otherwise, it will destroy the controller

11.3 The controller must be ground to the earth properly.

11.4 We suggest that the operators install the “ E- stop” key outside. Connecting the “E-stop” output terminal to the normal

contact of “E-stop” key, and the other point of contact must connect to the anode of working source.

11.5 Putting through the DC working source, confirming the preset parameter accord with actual running requirements.

Such as: current ratio, mode of speed sensor, mode of pressure sensor, mode of temperature, etc.

11.6

If the speed sensor is magnetic speed sensor, we must adjust speed measuring parameter

according to the following steps.

Method 1:

Loading...

Loading...